We are excited to announce that you can now select industrial FDM 3D printing and industrial SLA 3D printing through the Protolabs Network platform.

Upload your CAD file to get instant pricing today.

What are the advantages of Protolabs Network’s industrial FDM service?

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy and cost-efficiency. Industrial FDM takes place in a controlled build room, meaning consistent and repeatable quality. It uses a set catalog of branded materials with specific, high-performing properties that are ideal for end-use parts.

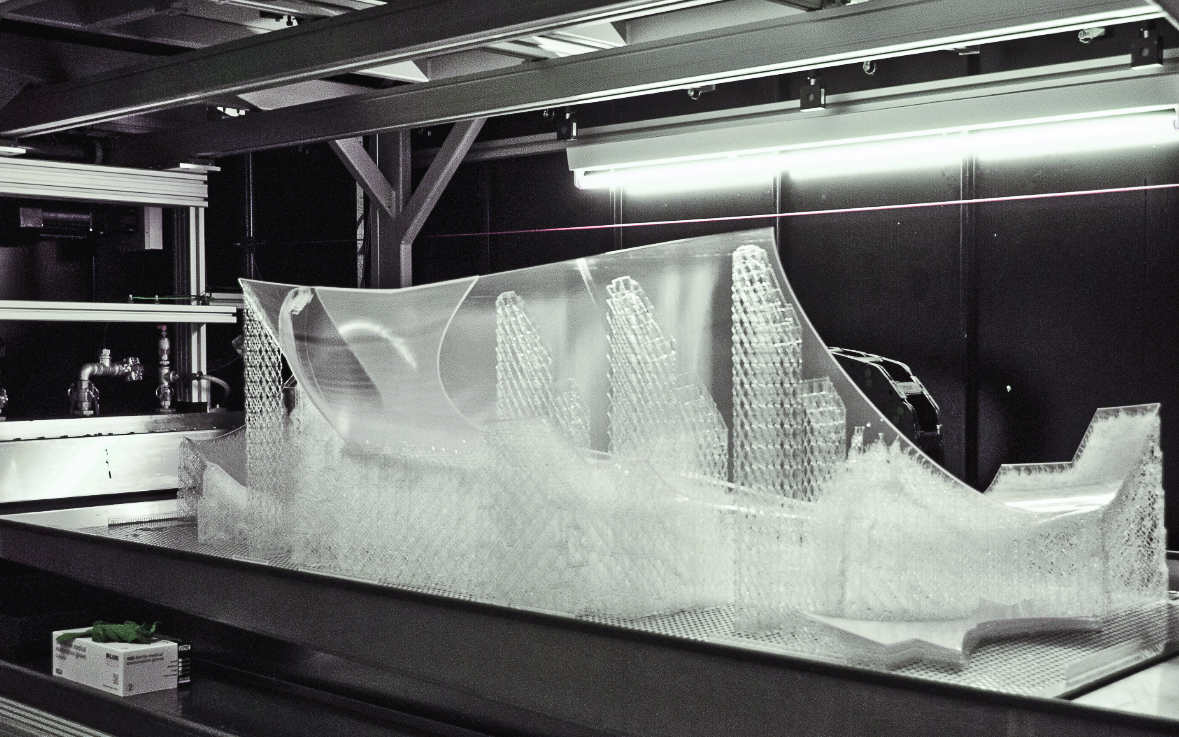

Image courtesy of Stratasys

Image courtesy of Stratasys

Build volumes

Protolabs Network’s industrial FDM 3D printing service offers large build volumes up to 406 x 355 x 406 mm on Stratasys Fortus platforms and 320 x 132 x 154mm on our Mark platforms.

- Industrial FDM: 406x355x406mm (914x609x914mm with manual review)

- Desktop FDM: 500x500x500mm

Materials

Material types: ABS M30, ASA, ULTEM 9085, ULTEM 1010, ABSPlus, Markforged Onyx

Layer heights

- 100 microns

- 180 microns

- 200 microns

- 330 microns

Protolabs Network’s FDM tolerance capabilities

- Industrial FDM: ±0.25% with a lower limit: ± 0.25 mm (0.01")

- Desktop FDM: ±0.5% with a lower limit of ±0.5 mm (±0.02″)

Find out more about the differences between desktop and industrial FDM.

What are the advantages of Protolabs Network’s industrial SLA service?

Industrial SLA printers can produce more accurate parts than desktop machines. Industrial machines typically produce parts in a controlled environment, use machine-specific materials and are built using high-cost components.

Build volumes

- Industrial SLA: 500x500x500mm

- Desktop SLA: 145x145x175mm

Materials

Material types: Accura Xtreme White 200, Accura Clearvue, Accura 25

Layer heights

- 50 microns

- 100 microns

Protolabs Network’s SLA tolerances capabilities

While desktop SLA printers are able to produce parts with tolerances of 150 - 300 microns (with this increasing significantly over larger parts), industrial machines are capable of tolerances as low as 30 microns for any build size.

- Industrial SLA: ±0.2% with a lower limit of ± 0.127 mm (±0.005")

- Desktop SLA: ±0.5% with a lower limit of ± 0.15 mm (±0.006″)

Find out more about the differences between desktop and industrial SLA.