In designing Norway-based Remotion’s robots, Senior Design Engineer Gediminas Mitkus has two primary concerns: cost and delivery time.

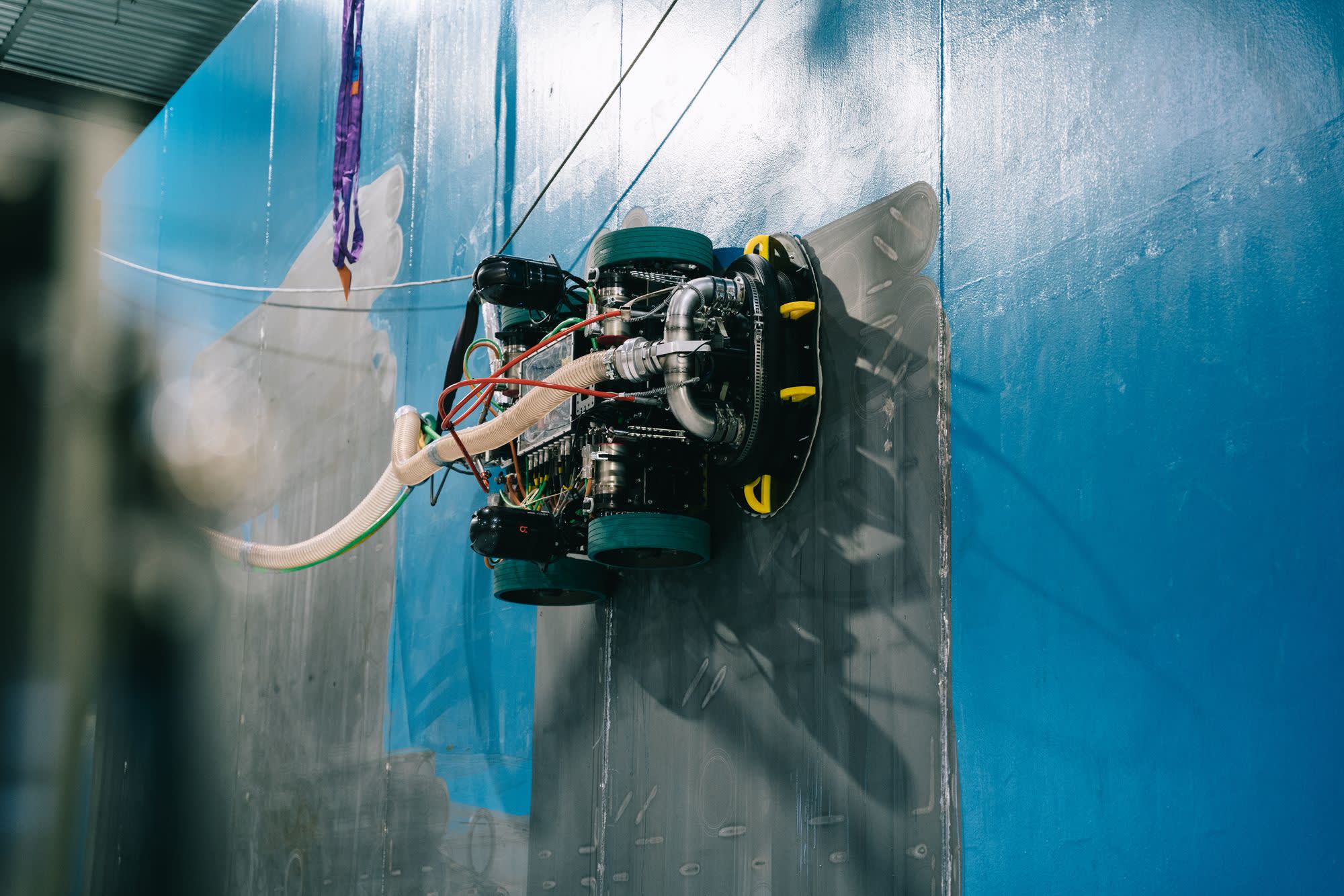

They also must be high-quality, of course, but that’s a given. The company’s robots are used for offshore applications on ships or floating platforms, and are often subject to harsh, potentially dangerous conditions. Recently, for instance, Remotion created a remote-controlled, magnetic robot that operators could use to sandblast a ship’s interior tank to remove rust and corrosion.

The structure of these robots – as well as brackets and supports for the cameras, tools, or other equipment attached to them – are predominantly CNC-machined out of aluminum. They are complex and intricate, with very tight tolerances. They’re also expensive to create, meaning minimizing manufacturing costs is an absolute necessity.

As Mitkus’s budgetary concern: when an issue arises offshore, it is typically an urgent one. Time, then, is of the essence, and Mitkus must act quickly to keep Remotion’s clients both operational and safe.

“We often have narrow windows in which to operate,” Mitkus said. “Sometimes the weather has an impact, but quite often the client requires immediate attention. For example, after inspection, they find something critical that needs repair.”

Remotion’s robots, however, are not a one-size-fits-all solution. Its clients have varying and far-ranging needs, meaning that the robots are tailored to specific jobs. This means that the parts Mitkus requires typically come in small orders – and that doesn’t always result in the best treatment from local manufacturers.

“Quite often, local vendors prioritize larger orders, and when you have a smaller order, it can sometimes feel like you’re just in the way,” he said. “That’s not the case with Hubs. It helps that we can order from them regardless of the quantity.”

Our combination of quality, speed, and low cost are game-changers to Mitkus and Remotion. With it – and sometimes combining it with Protolabs’ factories – they’re able to work as efficiently and effectively as possible, ensuring that clients have everything they need to navigate the rigorous challenges of offshore work.

“It’s great quality. It’s reasonably priced. It has a quick delivery time. The customer service is great,” he said. “There’s no reason not to use the network. And in the case we need something even faster, Protolabs makes it possible. Overall, it’s been a fantastic experience.”