Ready to test your design? Upload your parts for free DfM analysis.

Get instant quote

Material type

Metal

Material name

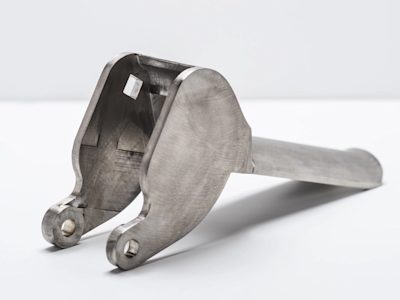

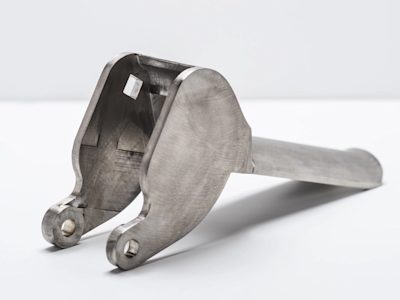

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Alternative names

42CrMo4, 1.7225

Process compatibility

CNC machining

AISI 4140 is low alloy steel with chromium and molybdenum content ensuring reasonable strength. Moreover it has good atmospheric corrosion resistance. It is widely used in many industries due to its excellent properties.