Introduction to mass production with injection molding

Injection molding is a manufacturing method where molten plastic is injected into a mold cavity under high pressure, cooled until solid, and then ejected as a finished part. It’s a widely used process for mass production because, once the mold is made, parts can be produced quickly, consistently, and at a low per-unit cost. Check out our injection molding guide to see how this process delivers at scale.

While it has many advantages, finding a good injection molding solution can be a daunting. It can take weeks of research, multiple calls, and navigating international suppliers just to secure a quote. These barriers can make high-quality injection molding difficult to access, particularly for startups. A digital manufacturing platform eliminates these challenges, providing instant access to vetted suppliers with guaranteed capacity and quality standards, so you can move from prototyping to production with less hassle.

Benefits of choosing our high-volume injection molding service

Many engineers think of platforms like Protolabs Network as ideal for prototyping. And while we’re great at helping you take those first steps, we’re also perfectly equipped to scale your project to production volumes. Need 10,000 parts? 100,000? Up to a million? We’ve got you covered—and it’s not just about the numbers.

Engineers use our high-volume injection molding production services because we offer guaranteed quality, competitive pricing (thanks to economies of scale), near unlimited capacity, and a pre-vetted network of specialized manufacturing partners. This means you can:

-

Instantly access a reliable injection molding facility that meets your needs.

-

Cut down on pre-production lead times and get your parts faster.

-

Build inventory as you need it, reducing waste and storage costs.

-

Take advantage of volume pricing for large production runs.

-

Customize orders with smaller quantities of multiple line items.

Scaling to production isn’t just about making more parts— it’s about making smarter decisions for your product development. Download our injection molding factsheet to find out more about our capabilities.

"Ready to scale with injection molding? Get started with our guide.

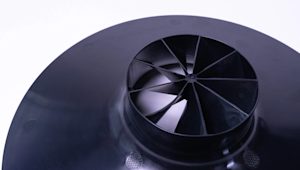

Download nowAccelerated production with multi-cavity molds

When speed matters (and let’s face it, it almost always does), multi-cavity molds make a big difference. Instead of producing one part at a time, these molds let you make multiples in a single shot, potentially cutting production time by as much as 50–80%, depending on the part and mold design.

To break it down, if a single-cavity mold takes 30 seconds per cycle, a four-cavity mold can produce four parts in the same time—effectively quadrupling output without adding extra labor or machine time. Not only does this help you keep up with demand, but it also brings down the cost per part, making large-scale production a lot more efficient.

So why not always use multi-cavity molds? Single-cavity molds come with a lower price tag for upfront tooling, can be better for large parts, and may prove easier for troubleshooting. It all depends on your production needs, part complexity, and budget. At Protolabs Network, we help you design the right mold setup to get the best balance of speed, quality, and cost.

Automation for consistent quality

Automation plays a starring role in getting every injection molded part to meet the same exacting quality standards, cycle after cycle. Many modern injection molding machines are equipped with robotic systems, precision sensors, and real-time monitoring software that regulate material flow, cooling time, and part ejection. Automated robotic arms remove parts quickly and consistently, preventing warping or defects caused by inconsistent cooling times. Smart sensors track production parameters in real time, making automatic adjustments to maintain quality. allowing for real-time quality control and process adjustments.

Automated quality checks—such as machine vision inspection and in-line measurement systems—spot defects immediately, so you can fix issues before you end up with a pile of faulty parts.

Through our network, engineers get access to specialized manufacturers that use state-of-the-art robotic systems for everything from material handling to post-production inspections. This minimizes the risk of human error and ensures that every part performs exactly as intended. And when you’re dealing with production volumes, that level of consistency is non-negotiable.

Material flexibility for custom manufacturing

There’s a lengthy menu of plastics to choose from, each with its own special characteristics. The right choice of injection molding materials depends on your application. Protolabs Network gives you access to a wide range of injection molding plastics, from tough, heat-tolerant thermoplastics to flexible, impact-resistant polymers. Beyond those listed on our platform, we can also source thousands of additional materials on request.

If you’re feeling lost in the labyrinth of plastics, our experts can help you find the perfect fit for your project by weighing cost, durability, and performance requirements.

Industries leveraging our high-volume injection molding

Some of the world’s most innovative businesses use Protolabs Network for injection molding. Here are just a few of the industries manufacturing more efficiently through our network:

-

Automotive: Companies likeLektrico rely on injection molding to produce high-performance vehicle components in large volumes.

-

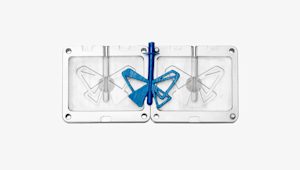

Medical: Organizations likeCircleg andFillauer Composites use injection molding to create reliable, lightweight prosthetics that improve mobility.

-

Consumer goods: Consumer brands likeZinstax use injection molding to manufacture high-volume consumer products with consistent results.

-

Electronics: Injection molding is a heavy-hitter for consumer electronics, used to churn out durable housings, connectors and enclosures that meet functional and aesthetic needs.

-

Industrial machinery: Engineers use injection molding to produce tough, wear-resistant components that keep heavy-duty equipment running reliably.

Tailored solutions for every injection molding project

Every project is different, and we get that. That’s why our injection molding production services are designed to adapt to your needs. Whether it’s adjusting for unusual part geometries, incorporating multiple materials, or optimizing for production speed, our experts are here to help.

We also offer flexibility in order sizes. Maybe you need one million of a single part—or maybe you need a few thousand each of several different parts. Either way, we’ll work with you to find the best approach.

Commitment to quality in every production run

What’s the point of mass production if the parts don’t measure up? At Protolabs Network, we’ve built our reputation on delivering high-quality parts, no matter the volume.

Our Protolabs Network Standard outlines rigorous quality assurance measures to ensure every part meets strict requirements for tolerances and dimensional accuracy, mold standards and quality control procedures. Here’s what that means for your production:

-

ISO-certified facilities (such as ISO 9001 and ISO 13485) for precision manufacturing.

-

Detailed inspections, dimensionally and visually, during and after production to check that every part meets your specifications.

-

Access to quality documentation like PPAP, Certificates of Conformance and Material Test Reports on request for added transparency.

Get a quote for high-volume injection molding

Ready to scale your project?Get a free quote to see how Protolabs Network can help you take your injection molding production to the next level.

Frequently asked questions

When should you use injection molding for production?

Injection molding production is ideal for high-volume manufacturing where repeatability, precision, and cost-effectiveness are key. Common applications includeautomotive parts,consumer electronics, andmedical devices.

What are the benefits of using injection molding for production volumes?

Injection molding offers high repeatability, low per-unit costs, and efficient large-scale production. Once the mold is made, parts can be produced quickly with minimal waste, making it ideal for manufacturing lots of parts with consistent quality.

How many parts can Protolabs Network produce?

We can handle production volumes of up to one million parts. Customization, including lower volumes of many different line items, is also one of our strengths.

What materials can I use for injection molding?

Our extensive material library includes a wide range ofplastics for injection molding, and we can source thousands of specialized materials on request.

How does on-demand production work?

On-demand production allows you to build inventory as needed, reducing upfront costs and storage requirements. It’s a flexible, price-competitive way to scale.