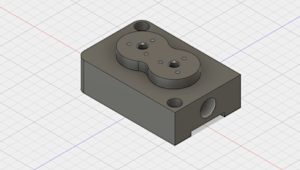

When your design demands precision components measured in millimeters (or smaller), CNC machining delivers the accuracy required to keep tiny parts performing reliably. From micro medical devices to aerospace connectors no bigger than a fingernail, these compact components prove that good things really can come in small packages

This guide covers the essentials engineers need to know when designing CNC small parts, including capabilities, materials, fixturing, DFM guidelines, and the applications where CNC machining packs mighty power into mini builds.

Why is CNC machining ideal for small parts?

CNC machining brings several advantages to small part production that other manufacturing methods struggle to match. Computer-controlled precision reduces human error, while rigid machine construction dampens vibration that could throw off tolerances on delicate features. Modern CNC machines can hold tolerances as tight as ±0.025 mm (±0.001") on features that might be only a few millimeters across.

The subtractive nature of CNC machining also means you're working from solid material blocks, giving small parts the structural integrity they need without the material inconsistencies that can appear in additive or molded parts. When a component needs to withstand stress despite its diminutive dimensions, starting from a solid billet makes all the difference.

Small parts benefit from several of CNC machining's core strengths:

-

High repeatability: CNC machines can reproduce tiny features with minimal variation across batches.

-

Excellent surface finish: End mills and turning tools can achieve clean edges and consistent finishes, which is critical for mating parts or sliding interfaces.

-

Wide material compatibility: Metals, plastics, and high-performance alloys can all be machined at small scales.

-

Scalability: A design that starts as a single prototype can use the same process to scale to thousands of units.

For engineering teams that need accurate, functional small parts fast, CNC machining remains one of the most dependable options.

CNC capabilities for small geometries

Small parts can be machined on a range of CNC setups, each offering different advantages depending on feature size, tool access, and tolerance requirements. Most miniature components are produced with one or a combination of the following machining approaches:

-

3-axis machining: A cost-effective, reliable option for prismatic parts, flat surfaces, pockets, and standard drilled features.

-

5-axis machining: Provides multi-angle access in a single setup, improving accuracy for complex surfaces, tight areas, and angled microfeatures.

-

2+3-axis machining: Uses a 3-axis mill with an indexing rotary or tilt table to reach multiple faces efficiently. An affordable middle ground for small parts that need angled or multi-sided features without full 5-axis interpolation.

-

Turning and mill-turn machining: Ideal for cylindrical small parts, precision diameters, threads, and components requiring both turning and milled details.

-

Swiss machining: Offers exceptional precision and rigidity for very small or slender parts, making it a top choice for medical, aerospace, and electronics components.

Want to learn more about the main CNC machine types? Watch our short explainer video about the different types of CNC machining.

Materials for small CNC parts

Material performance becomes even more important at small scales. Here’s a comparison table with data engineers use most often when comparing CNC metals and plastics.

| Material | Typical tolerances | Minimum wall thickness | Notes on machinability | Common small-part applications |

|---|---|---|---|---|

| Aluminum (6061, 7075) | ±0.025–0.05 mm | 0.5–0.8 mm | Very machinable, low tool wear, excellent chip evacuation | Electronics housings, connectors, optical mounts |

| Stainless steel (304, 316, 17-4 PH) | ±0.025–0.05 mm | 0.8–1.0 mm | Harder to machine; requires slower feeds/speeds; strong threads | Surgical tools, structural components, mini mechanical parts |

| Titanium (Grade 2, Grade 5) | ±0.025–0.05 mm | 0.8–1.0 mm | Generates heat; slower machining; excellent strength-to-weight | Aerospace brackets, implants, high-performance fasteners |

| Copper alloys (C110, brass, bronze) | ±0.025–0.05 mm | 0.6–0.8 mm | Pure copper can be gummy; brass machines very well; high conductivity | RF connectors, heat spreaders, electrical interfaces |

| Plastics (Delrin, ABS, nylon, PC) | ±0.125 mm (±0.005″) | 1.0–1.5 mm | Soft materials may deflect; excellent for prototypes; good surface finish | Sensor housings, consumer electronics, lightweight prototypes |

Workholding strategies for small components

Small parts need secure, lightweight setups that hold the workpiece firmly without distortion.

-

Soft jaws: Custom‑machined aluminum or plastic jaws that grip delicate shapes without marking them.

-

Vise parallels and mini‑vises: Support thin or narrow parts while keeping clamping forces low.

-

Vacuum fixtures: Useful for flat, thin, or flexible pieces that can’t be clamped traditionally.

-

Collets and mandrels: Provide excellent grip and concentricity for small turned parts.

-

Micro end mills (0.1–2 mm): Allow precise slots, pockets, and fine features.

-

Small‑diameter drills: Create accurate holes and fine threads in tiny geometries.

-

Specialized tool coatings: Reduce heat and wear when cutting tougher metals like stainless steel or titanium.

Using the right workholding and tools minimizes vibration, protects fragile features, and keeps tiny components machining cleanly and consistently.

DFM tips for CNC small parts

Often, the smallest parts require the highest precision. Smart design choices make the difference between small parts that machine efficiently and those that push manufacturing limits unnecessarily.

-

Minimum wall thickness: Aluminum typically needs 0.5–0.8 mm, plastics 1.0–1.5 mm, and stainless steel or titanium 0.8–1.0 mm to maintain rigidity.

-

Minimum feature size: Internal radii typically fall in the 0.2–0.5 mm range depending on cutter diameter.

-

Hole diameters: Aim for drilled holes ≥ 1 mm, as threads smaller than M2 become difficult.

-

Thread options: Use M2–M3 threads, helicoils for soft metals, and thread milling for flexibility.

-

Chamfers and radii: Add 0.2–0.5 mm chamfers and match internal radii to standard cutter sizes.

-

Part orientation: Position the part to minimize setups, improve access, and reduce vibration in thin or flexible areas.

For more comprehensive guidance, see our knowledge base on designing parts for CNC machining.

Using CNC small parts for prototyping and production

When parts are only a few millimeters across, material behavior becomes very important. CNC machining lets you validate stiffness, heat resistance, wear, and surface finish in the final production material from the very first prototype, which is crucial for miniature connectors, sleeves, brackets, and housings where tiny variations can affect performance.

CNC machining also makes it easy to move from prototype to production because the same digital program works at any volume. You can start with simple 3‑axis setups for a handful of test parts, then shift to multi‑part fixtures or small‑part‑specific workholding as quantities increase.

Protolabs Network is particularly well suited for producing small parts thanks to its network of partners who specialize in tight tolerances, micro-features, and the workholding setups that tiny components demand. Whether you need 10 prototypes or 10,000 production units, Protolabs’ CNC machining services provide consistent accuracy across every batch.

Industries relying on miniature precision

Small CNC parts punch above their weight across industries where precision is a heavy consideration. Here's where miniature machined components make their biggest impact.

-

Medical devices: CNC is widely used for surgical tools, implant hardware, and diagnostic equipment because it delivers the precision, smooth finishes, and biocompatible materials these small-scale, high-stakes parts need.

-

Connectors and electronics: RF connectors, heat spreaders, and sensor housings depend on CNC machining for tight mating features, excellent conductivity in copper alloys, and stable geometries that keep assemblies reliable.

-

Aerospace: Lightweight brackets, housings, and high-strength fittings require durability, and repeatable tolerances across batches, which is why CNC machining is often used for aerospace.

-

Automotive sensors: Housings, thermal components, and pressure-sensitive interfaces use CNC machining for reliability, heat resistance, and airtight dimensional accuracy.

-

Robotics: Small CNC-machined parts power joints, end-effectors, sensor mounts, and actuation systems. CNC delivers the stiffness, repeatability, and wear resistance these motion-heavy components need to stay accurate over time.

Get started

Does your next big idea depend on small parts? Upload your CAD file for an instant quote and let high-precision CNC machining bring the little details to life.

Frequently asked questions

What is considered a “small” CNC part?

Most manufacturers treat parts under 100 mm in any dimension as “small,” and many produce components that are only a few millimeters across.

How tight can CNC tolerances be on small parts?

Typical tolerances are ±0.025 mm, with some metals reaching ±0.01 mm. Plastics usually fall in the ±0.05–0.1 mm range.

What’s the difference between micro-machining and small-part machining?

Micro-machining targets micron-scale features using specialized equipment. Small-part machining covers roughly the 1–50 mm range using standard CNC machines.

Do small parts cost less because they use less material?

Usually not. Reduced material use is offset by the extra fixturing, tooling, and careful setup that tiny parts require.