What is Manufacturing-as-a-Service (MaaS)?

Manufacturing-as-a-Service (MaaS) applies the 'as-a-service' model, made famous by software and cloud computing, to the manufacturing industry. By leveraging digital platforms, MaaS connects businesses to a distributed solution for advanced manufacturing resources, offering on-demand access to scalable, flexible, and efficient production capabilities.

Introduction to Manufacturing-as-a-Service (MaaS)

While ride-scheduling and food-delivery services take advantage of machine-learning and advanced algorithms to automate the bottlenecks, it is an odd anachronism that engineers often have to pick up the phone and call around to find a reliable facility to manufacture their designs. Manufacturing-as-a-Service (MaaS) provides the same level of ease that’s long been available in other industries to manufacturing, offering a flexible, decentralized solution that connects businesses with global manufacturing capabilities for rapid prototyping, small-batch production, or large-scale manufacturing.

This article explains what MaaS is and how it is reshaping the future of production.

How does Manufacturing-as-a-Service (MaaS) work?

Manufacturing-as-a-Service (MaaS) works by streamlining the production process through digital platforms. Instead of the traditional approach—contacting multiple suppliers, negotiating pricing, and waiting on long lead times—users can upload their designs, receive instant quotes, and place orders in minutes. The platform then matches each order with a vetted manufacturer that has the right capabilities and availability. This helps optimize each project for cost, speed, and quality.

MaaS is considered a service because it transforms manufacturing from a transaction-based model into an on-demand, platform-driven experience— similar to how SaaS (Software-as-a-Service) delivers software without requiring ownership of infrastructure. Instead of committing to long-term contracts or investing in dedicated suppliers, businesses can access manufacturing capabilities flexibly, paying only for what they need, when they need it. The platform offers the service of handling supplier matchmaking, pricing, production management, and logistics, making the entire process faster, more flexible, and more efficient.

Benefits of MaaS in distributed production

Manufacturing-as-a-Service leverages a system of distributed production where parts and products are manufactured across multiple locations rather than in centralized facilities. Here’s why that matters:

-

Flexibility and scalability: MaaS platforms allow businesses to scale production up or down based on demand, without requiring large capital investments.

-

Faster lead times: Distributed networks reduce logistical bottlenecks for quicker delivery. Engineers can move parts into production in minutes, which means engineering companies can bring new products to market faster than ever before.

-

Global access: Companies can source manufacturing capabilities anywhere, tapping into unlimited capacity, diverse expertise and myriad technologies.

-

Fair pricing: Instead of being locked into fixed prices from a few local manufacturers, businesses can compare options and choose the best mix of cost, speed, and quality.

-

Lower risk: MaaS takes away the need for big upfront investments in equipment and contracts. Going with a distributed network means avoiding supply chain disruptions, equipment failures, and capacity issues, so production is more reliable and resilient.

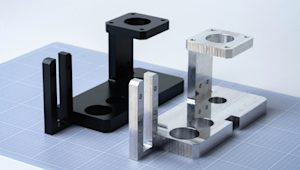

MaaS solutions, like Protolabs Network, offer an extensive network of manufacturing partners to fulfill everything from CNC machining and 3D printing to injection molding. By providing instant pricing, design feedback, and seamless order management, Protolabs Network simplifies on-demand production for engineers worldwide.

How MaaS is transforming traditional manufacturing models

Traditional manufacturing comes with a bevy of challenges. The process for producing everything from sneakers to airplane parts is bloated with long lead times to assess designs and quote prices. It can take weeks just to get an estimate. Smaller companies without access to their own machine shops have to join the queue at various suppliers. MaaS flips this model by:

-

Offering instant access to vetted suppliers: Engineers don’t have to spend weeks searching for a reliable manufacturer or negotiating pricing.

-

Leveling the playing field: MaaS gives startups access to top-tier manufacturing, helping them compete with industry giants on a global scale.

-

Facilitating faster iteration: Shorter lead times and instant quotes mean companies can refine products and get them to market faster than ever.

Key technologies enabling MaaS

The success of MaaS is driven by advanced technologies that seamlessly connect engineers and manufacturers:

-

Cloud computing: Centralizes data, enabling instant quoting and design sharing.

-

Internet of Things (IoT): Provides real-time tracking of manufacturing processes and inventory.

-

AI and machine learning: Optimizes production schedules, identifies cost-saving opportunities, generates instant quotes based on historical data and supplier availability, provides automated design feedback, and matches projects with the most efficient solutions

-

Digital twins: Simulates production environments to refine designs before manufacturing begins.

Platforms like Protolabs Network integrate these technologies, making on-demand manufacturing more accessible and reliable than ever.

Challenges in adopting MaaS

While MaaS offers significant benefits, shifting from traditional manufacturing to a distributed, on-demand model isn’t always easy. Companies that have only worked directly with a small set of trusted suppliers may struggle with new procurement processes, quality assurance, and supply chain visibility. Key challenges include:

-

Procurement complexity: Traditional procurement teams are used to working with a fixed set of suppliers. Adapting to a dynamic, digital network requires new workflows, vetting processes, and contract management strategies.

-

Integration with legacy systems: Many manufacturers still rely on outdated ERP and supply chain management tools that may not easily connect with MaaS platforms.

-

Managing production visibility: With MaaS distributing production across multiple suppliers, real-time visibility can be more complex, making it harder to track progress or address issues quickly.

-

Overcoming internal resistance: Teams accustomed to long-term supplier relationships may be hesitant to shift to an on-demand model, especially if they’re unfamiliar with how distributed manufacturing works.

-

Ensuring quality consistency: With parts coming from different manufacturers, maintaining uniform quality and meeting tight tolerances across multiple production runs can be tricky. Solutions like Protolabs Network work to address these concerns with comprehensive quality assurance and systems for continually vetting their supplier network.

Future outlook: MaaS and the shift towards globalized production

MaaS is already reshaping global production, but with the launch of OpenAI and DeepSeek, a new era of transformation is just dawning. As AI, IoT, and automation evolve, manufacturing will become faster, leaner, and more adaptive. Here’s what’s next:

-

AI-powered design: Intelligent assistants will help engineers refine designs in real-time, predict manufacturability issues, and optimize for cost and sustainability before production even begins.

-

Smarter local production: AI will match orders with the best nearby supplier, cutting lead times and emissions.

-

Custom at scale: Advances in manufacturing will make mass customization faster and more cost-effective, blurring the line between personalized and mass-market production.

-

Self-optimizing supply chains: AI will predict disruptions, reroute production, and keep everything running smoothly with little to no human intervention.

-

Next-level collaboration: AI will drive innovation by connecting industries like never before, fueling breakthroughs in product development and materials science.

The future of MaaS isn’t just about making things faster and cheaper—it’s about making them smarter and better.

Ready to streamline your production process?

Upload your CAD files now for a free, instant quote.

Frequently asked questions

Which industries benefit most from MaaS?

Industries like automotive, aerospace, medical devices, and consumer electronics benefit greatly due to their need for rapid prototyping, precision, and scalability.

How is MaaS different from traditional manufacturing?

Traditional manufacturing relies on centralized facilities and long lead times, whereas MaaS leverages digital platforms and distributed networks for faster, more flexible production.

What role does Protolabs Network play in MaaS?

Protolabs Network connects engineers and businesses to a global network of manufacturing partners, offering instant quoting, design feedback, and streamlined production across multiple technologies.