What are the SPI surface finishes available through Protolabs Network?

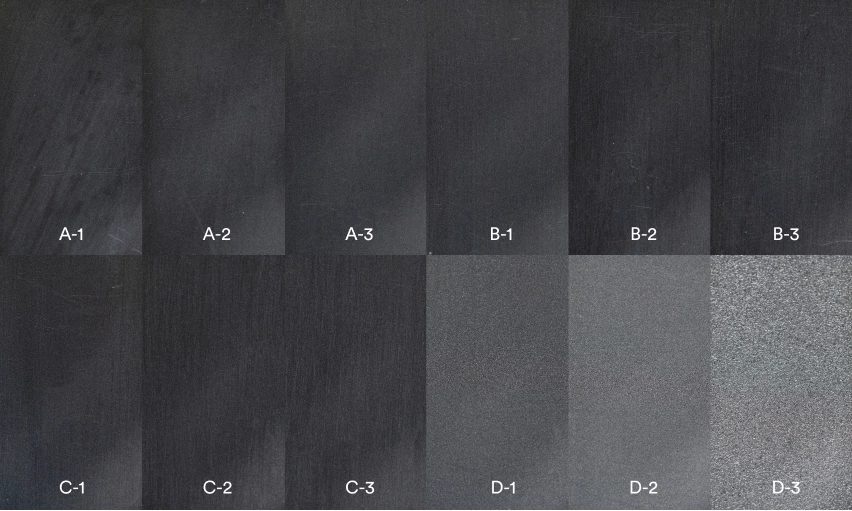

This table contains all of the SPI injection molding surface finishes we offer.

| Finish | SPI* standard | Finishing Method | Typical surface roughness Ra (μm) |

|---|---|---|---|

| Super High Glossy finish | A-1 | Grade #3, 6000 Grit Diamond Buff | 0.012 to 0.025 |

| High Glossy finish | A-2 | Grade #6, 3000 Grit Diamond Buff | 0.025 to 0.05 |

| Normal Glossy finish | A-3 | Grade #15, 1200 Grit Diamond Buff | 0.05 to 0.10 |

| Fine Semi-glossy finish | B-1 | 600 Grit Paper | 0.05 to 0.10 |

| Medium Semi-glossy finish | B-2 | 400 Grit Paper | 0.10 to 0.15 |

| Normal Semi-glossy finish | B-3 | 320 Grit Paper | 0.28 to 0.32 |

| Fine Matte finish | C-1 | 600 Grit Stone | 0.35 to 0.40 |

| Medium Matte finish | C-2 | 400 Grit Stone | 0.45 to 0.55 |

| Normal Matte finish | C-3 | 320 Grit Stone | 0.63 to 0.70 |

| Satin Textured finish | D-1 | Dry Blast Glass Bead #11 | 0.80 to 1.00 |

| Dull Textured finish | D-2 | Dry Blast #240 Oxide | 1.00 to 2.80 |

| Rough Textured finish | D-3 | Dry Blast #24 Oxide | 3.20 to 18.0 |

| As machined | - | Finished to the machinist’s discretion | 3.20 (with visible machining marks) |

- SPI (Plastics Industry Trade Association) standards

To get started with injection molding or get a quick refresher before manufacturing your custom parts, check out our comprehensive guide to injection molding.

What’s the right material for each SPI surface finish?

SPI surface/mold finishes produce different results depending on the material you use for injection molding components. The tables below detail how to select the right mold finish and materials for your specific application.

Glossy finish

| Material | A-1 | A-2 | A-3 |

|---|---|---|---|

| ABS | Average | Average | Good |

| Polypropylene (PP) | Not recommended | Average | Average |

| Polystyrene (PS) | Average | Average | Good |

| HDPE | Not recommended | Average | Average |

| Nylon | Average | Average | Good |

| Polycarbonate (PC) | Average | Good | Excellent |

| Polyurethane (TPU) | Not recommended | Not recommended | Not recommended |

| Acrylic | Excellent | Excellent | Excellent |

Semi-glossy finish

| Material | B-1 | B-2 | B-3 |

|---|---|---|---|

| ABS | Good | Good | Excellent |

| Polypropylene (PP) | Good | Good | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Good | Good | Excellent |

| Nylon | Good | Excellent | Excellent |

| Polycarbonate (PC) | Good | Good | Average |

| Polyurethane (TPU) | Not recommended | Average | Average |

| Acrylic | Good | Good | Good |

Matte finish

| Material | C-1 | C-2 | C-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Excellent |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Excellent |

| Polycarbonate (PC) | Average | Not recommended | Not recommended |

| Polyurethane (TPU) | Good | Good | Good |

| Acrylic | Good | Good | Good |

Textured finish

| Material | D-1 | D-2 | D-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Good |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Good |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Good |

| Polycarbonate (PC) | Excellent | Not recommended | Not recommended |

| Polyurethane (TPU) | Excellent | Excellent | Good |

| Acrylic | Average | Average | Average |

Need more advice on injection molding custom parts?

Frequently asked questions

What are SPI surface finishes?

SPI surface finishes refer to the predominant global surface finish standard set by the Plastics Industry Trade Association (SPI). It covers the 12 grades of SPI mold finishes. You can also refer to SPI surface finishes as SPI mold finishes.

What is the VDI 3400 standard?

While SPI surface finishes are widely used around the world, they aren’t the only mold finishes. The other standard to consider is the VDI 3400 texture or surface finish standard. Set by the Society of German Engineers, it covers 45 grades of texture for injection molded parts.