Laser engraving is one of the most popular part-marking services for adding serial numbers, traceability, branding, or labels to production parts. Whether you're shipping parts to a controlled environment (like a cleanroom), meeting compliance requirements, or just want your logo to last, laser engraving delivers results that won't fade, smudge, or wear off.

In this guide, we’ll cover what laser engraving is, where it fits into manufacturing workflows, and how to get crisp, consistent marks on your parts.

What is laser engraving?

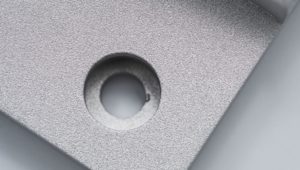

Laser engraving uses a focused beam of light to remove a small amount of material from the surface of a part. That removal process leaves behind a mark, like a number, logo, barcode, or image, which remains permanent and precise.

Unlike ink-based printing, engraving doesn’t involve any contact with the part. That means it works well on parts with tight tolerances because it doesn’t introduce debris or smudging. It’s also more durable and well-suited for harsh or outdoor environments.

There are three main types of laser marking:

-

Laser engraving removes material to create a deep, long-lasting mark.

-

Laser etching melts the surface to make a faster, shallower mark, which can work well with coated or softer materials.

-

Laser annealing heats the surface (usually of metals like stainless steel) to create a color change without removing any material.

Laser engraving is compatible with many manufacturing processes, including CNC machining, sheet metal fabrication, and 3D printing. It’s most commonly used on metal parts, but certain plastics like ABS and acrylic also engrave nicely.

Interested in other ways lasers are leveraged in manufacturing? This introduction to laser cutting explains how it can be used to shape parts, not just mark them.

How is laser engraving used for end-use products?

Laser engraving adds details—like serial numbers, barcodes, or logos—to finished parts. These marks often help with product identification, compliance, and tracking once parts leave the factory. Unlike temporary labels or printed ink, engraving won’t rub off, so it can handle demanding use cases.

That’s why it’s frequently included in production orders as teams move from prototypes to volume manufacturing. It’s a reliable and repeatable process that doesn’t require extra assembly steps or slow down production.

Engraving is often an integral part of the workflow for industries where parts must carry data throughout their lifecycle:

-

Aerospace manufacturing: For flight-critical parts, every component must be traceable. Engraving makes it easy to apply unique serial numbers that can survive heat, wear, and extreme environments.

-

Medical manufacturing: Instruments, implants, and disposable tools may require engraved Unique Device Identification codes or part IDs to meet regulations and maintain traceability through sterilization and use.

-

Automotive manufacturing: Parts like engine components, brake systems, and Vehicle Identification Number plates rely on engraved marks for quality control, warranty tracking, and safety compliance.

-

Electronics manufacturing: Logos, barcodes, and version indicators help improve usability and assembly on enclosures and printed circuit boards.

Benefits of laser engraving

Laser engraving is a high-precision, non-contact process that works across a wide range of materials and manufacturing methods. It’s fast, clean, and easily automated, making it a practical way to mark everything from metal brackets to plastic enclosures. It’s also surprisingly affordable at scale compared to more short-term options, like ink stamping or labels, and is ideal for companies ramping up production.

Because it delivers reliable, consistent results without interrupting your workflow, laser engraving is a great solution for traceability, branding, and quality assurance. It slots easily into production processes, no matter your volume or part complexity.

-

Permanence: The markings hold up over time, resisting scratches, fading, and exposure to chemicals.

-

Precision: Even small, detailed designs like logos or barcodes come out clearly and accurately.

-

Repeatability: Every part in a batch gets the same consistent mark with no variation.

-

Non-contact process: The laser doesn’t physically touch the part, so there’s no risk of damage or deformation.

-

Minimal impact: Engraving only affects the surface, so it doesn’t interfere with part strength or tolerances.

-

Speed: Laser systems can engrave large volumes of parts quickly and efficiently.

-

Material and process flexibility: Compatible with a range of metals and plastics and works across CNC, 3D printing, and sheet metal fabrication.

-

Cost efficiency at scale: Once the setup is complete, applying the engraving is quick and low-cost for high volumes.

Compared to alternatives like ink stamping or adhesive labels, engraving stands out for durability and professional appearance, which are essential when regulations or brand expectations call for markings that won’t wear off.

Laser engraving material considerations

Some materials are naturally suited to laser engraving, producing high-contrast marks that are easy to read. For example, aluminum and acrylic tend to darken or whiten where lasered, for a strong visual contrast. Others, like Teflon or Delrin, don’t absorb the laser energy well, so the marks come out faint. Or, even worse, the material can melt under the heat and release toxic fumes. That’s why material choice is one of the most important factors in getting reliable, legible results.

Best materials for laser engraving:

-

Metals: Aluminum, stainless steel, copper, and brass. These metals engrave cleanly with sharp results.

-

Plastics: ABS, acrylic (PMMA), polycarbonate, and nylon: These plastics can be engraved successfully, particularly when they include laser-sensitive additives, like carbon black or metal oxides, that help the plastic absorb laser energy more effectively.

Materials to avoid:

-

PVC: Engraving PVC releases toxic chlorine gas that is hazardous to operators and equipment.

-

PTFE (Teflon): Its fluoropolymer structure resists laser energy, so you end up with poor contrast and low durability.

-

POM/Delrin: It releases formaldehyde fumes when lasered. Marks are faint and low contrast.

If you aren’t sure about the best material for your part, contact networksales@protolabs.com and someone from our team can help you decide.

Laser-engraving material comparison

| Material | Laser engraving | Technologies | Notes |

|---|---|---|---|

| Aluminum | Excellent | CNC, sheet metal | Great contrast, very readable. |

| Stainless steel | Excellent | CNC, sheet metal | Tough and stays readable even after wear. |

| Copper | Good | CNC | Shiny surfaces can reflect the laser, leading to shallower marks. |

| Brass | Good | CNC | Engraves well but can fade a bit over time. |

| ABS | Good | CNC, 3DP | Makes crisp, clean marks. Great for enclosures. |

| PMMA / Acrylic | Good | CNC, 3DP | High contrast. Just avoid very thin walls. |

| Polycarbonate | Good | CNC, 3DP | Good contrast, easy to engrave. |

| Nylon | Fair | CNC, 3DP | Can look faint. Darker colors help. |

| PVC | Not recommended | CNC | Can’t be engraved due to unsafe fumes. |

| PTFE / Teflon | Not recommended | CNC | Doesn’t engrave well, results in low visibility. |

| POM / Delrin | Not recommended | CNC | Faint marks and releases bad fumes. |

Best surface finishes for laser engraving

Engraving on top of a finished surface helps create strong contrast and improves mark durability, particularly for colored or coated parts. Here are a few finishes that pair particularly well with laser engraving:

-

Anodizing: An electrochemical process that thickens the oxide layer on aluminum, improving corrosion resistance and allowing for dye-based coloring. Engraving on anodized surfaces burns through the color layer to create high-contrast marks.

-

Powder coating: A dry finishing process that applies a durable polymer layer to the surface. Engraving after powder coating exposes the base material, giving the mark a sharp, readable finish.

-

Chromate conversion coating: A chemical treatment for aluminum that improves corrosion resistance while maintaining conductivity. Engraving on top of this finish helps maintain clear markings without compromising the protective layer.

For a full breakdown, see our surface finishing options.

Design tips for engraving production parts

If you’re having something engraved into thousands of parts, you want to make sure you get it right. No blurry logos, unreadable QR codes, or typos—just crisp, consistent marks every time.

-

Use vector files: Formats like AI, SVG, or DXF give clean, scalable results.

-

Call out locations: Add engraving zones to your CAD or upload a technical drawing.

-

Check the scale: Text and logos should be at least 1mm tall for readability, though larger sizes work better for fast scanning.

-

Stick to flat areas: Engraving curved surfaces can cause distortion or blur, especially for Data Matrix codes, which are small 2D barcodes used for tracking and tracing.

-

Plan for finishing: Marking typically happens after surface treatments. If you anodize or coat parts after the engraving, marks may fade.

Engraving is generally one of the last production steps, so it’s important to finalize dimensions and part finishes first. If in doubt, talk to your Account Manager or email networksales@protolabs.com for feedback.

Alternative marking methods

Laser engraving is tough to beat on durability and precision, but in some cases, other marking methods may offer better flexibility, speed, or cost—especially if durability isn't the top priority.

-

Pad printing: This method uses a soft silicone pad to transfer ink from an etched plate onto a part’s surface. It can print logos or text in color, and works particularly well on irregular or curved surfaces. It’s good for branding or decoration, but the ink can wear over time. Example: logos on bicycle helmets.

-

Silk screening: Also known as screen printing, this process pushes ink through a stencil on a mesh screen to apply flat, colorful labels. It’s used for high-volume production of simple markings. Example: graphics on T-shirts or branding on promotional items.

-

Inkjet or thermal transfer: These digital printing techniques are used to apply high-resolution text, barcodes, or date codes. They're fast and flexible, but the markings are less durable—best for packaging or indoor-use products. Example: expiration dates on snack wrappers.

-

Adhesive labels: Printed stickers that can be applied to parts for tracking, branding, or instructions. They’re inexpensive and flexible, but not suitable for high-wear or high-temperature environments. Example: tracking QR codes stuck to laptops or office equipment.

If permanence, chemical resistance, or traceability are critical to your product, laser engraving is still your best bet.

Does Protolabs Network offer laser engraving?

Yes, Protolabs Network offers laser engraving. It’s one of our most frequently added post-processing services for production orders. While it's not currently a built-in option in our quote builder, it's easy to submit as a custom request.

To get started, just email networksales@protolabs.com with your part-marking requirements. You can also provide a CAD file, a vector file (typically in AI, DXF, or SVG format for logos or barcodes), and a technical drawing (PDF format) that shows engraving size and placement.

Learn more

Looking to scratch beneath the surface of laser engraving? Here are a few helpful resources:

Need a material that holds up under pressure? Upload your CAD file to get a free, instant quote.

Get a quoteFrequently asked questions

What materials can be laser engraved?

Laser engraving works well on most metals and select plastics like ABS, polycarbonate, nylon, and acrylic (PMMA).

Is laser engraving permanent?

Yes, it creates long-lasting marks that resist wear, heat, and chemicals.

Can I request laser engraving on prototypes?

Yes. While it’s more standard on production orders, prototypes can also be engraved through a custom request.

How much does laser engraving cost?

It depends on the part size, material, and quantity. Costs are relatively low for production volumes.

What’s the difference between engraving and etching?

Engraving removes material for a deep mark. Etching is shallower and often faster, but may be less durable.

Can I engrave logos, barcodes, or QR codes?

Yes. All of these are commonly engraved for traceability and branding.

What file types are best for submitting engraving instructions?

Send your CAD file and any artwork files (like .DXF or .AI) with instructions on size, location, and content.

Is engraving available on all manufacturing methods?

It works best with CNC machining, sheet metal fabrication, and some 3D printed parts.