In this article, we’ll take a closer look at each material’s properties, their most common manufacturing processes, applications for which they are used, costs, advantages and disadvantages, and more.

What is polycarbonate?

Polycarbonate (PC) is a durable, transparent thermoplastic polymer that is known for its high performance in industrial applications. Here are a few of its most important beneficial properties.

-

High impact resistance. Compared to other similar plastics, polycarbonate can withstand significant physical impact without cracking or breaking. You can even drill into polycarbonate.

-

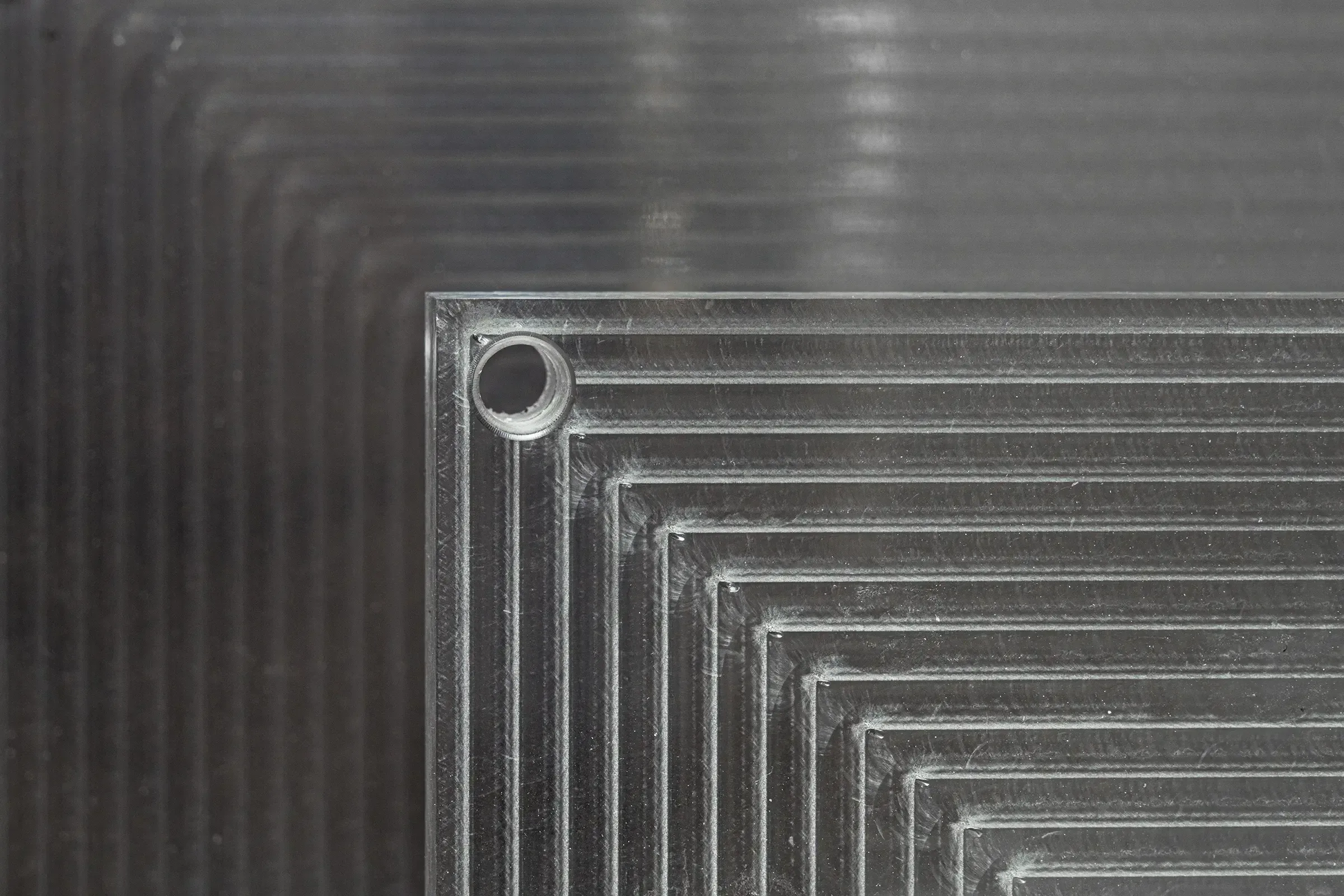

Optical clarity. Polycarbonate is highly transparent, and allows up to 88% of visible light to pass through it. For comparison, window glass has around 92% transparency.

-

Thermal stability. Polycarbonate maintains its shape and strength over a wide temperature range.

-

Chemical resistance. Polycarbonate is highly chemical resistant, making it a good choice for applications where it may come into contact with them

-

Lightweight. Despite its strength and durability, polycarbonate is lightweight, which makes it easy to handle and reduces the overall weight of products in which it is used.

-

Good electrical insulation. Polycarbonate is an excellent electrical insulator, and help protect sensitive components from electrical currents and short circuits.

-

High dimensional stability: Polycarbonate exhibits low shrinkage and high dimensional stability, which helps keep parts in size and shape even after molding. It can also be shaped at room temperature.

What is acrylic?

Acrylic (polymethyl methacrylate, PMMA) is also a transparent thermoplastic. Here, we’ll examine the characteristics and advantages of the material, before moving on to a comparison between acrylic and polycarbonate.

-

High optical clarity: Acrylic offers exceptional transparency, allowing up to 92% of visible light to pass through.

-

Weather resistance. Acrylic is highly resistant to weathering and UV light, maintaining its clarity and color even when exposed to the elements.

-

Lightweight: Acrylic is lighter than glass and many other plastics, making it easier to handle and reducing the weight of products in which it is used.

-

Impact resistance. Although it is less impact-resistant than polycarbonate, acrylic still provides better impact resistance than glass.

-

Scratch resistance: Acrylic has a harder surface than many other plastics, and as such offers good resistance to scratching and abrasion.

-

Polishing. You can polish acrylic to remove scratching or clean up a part’s edges.

What are the key differences between acrylic and polycarbonate?

Now that we've gone over the properties of acrylic and polycarbonate, let's put them side by side, so we can accurately compare the two.

-

Optical clarity. Acrylic has a better optical clarity than polycarbonate, transmitting up to 92% of visible light against polycarbonate’s 88%.

-

Impact resistance. Acrylic is less impact-resistant than polycarbonate, but both are more impact-resistant than glass.

-

Weather resistance. Acrylic exhibits excellent resistance to weather and UV light, and is able to maintain its color and clarity outdoors. Polycarbonate can offer good weather resistance, but must first be treated with UV additives to prevent it from yellowing.

-

Weight. Both materials are very lightweight, although acrylic is generally lighter than polycarbonate.

-

Scratch resistance. Acrylic is harder than polycarbonate, making it less prone to scratching.

-

Thermal stability. Polycarbonate outshines acrylics when it comes to thermal stability, performing well across a wider range of temperatures.

-

Ease of fabrication. Both materials are easy to work with, however acrylic edges out polycarbonate here, as polycarbonate’s higher impact resistance can make it tricker to cut or bend.

-

Electrical insulation. While acrylic offers good electrical insulation, polycarbonate’s is excellent, and is often preferred for electronic components.

-

Flame retardancy. Polycarbonate is more flame retardant than acrylic. It is also self-extinguishing.

-

Dimensional stability. While acrylic maintains its size and shape well, and is suitable for precise applications, polycarbonate is better for demanding applications that require durability under stress.

What are the costs of acrylic and polycarbonate?

Acrylic is typically cheaper than polycarbonate. However, because it is more brittle and prone to cracking that polycarbonate, it may be more costly to maintain. Additionally, polycarbonate’s durability means it may be more cost-effective in the long run, despite having higher manufacturing costs. What manufacturing methods work best with acrylic and polycarbonate? Acrylic and polycarbonate are used in many of the same manufacturing methods. Here are the most common.

-

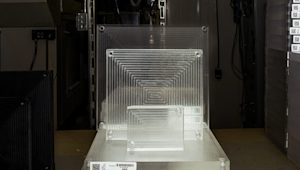

CNC machining. Perhaps the most commonly used manufacturing method for acrylic and polycarbonate, CNC machining allows you to create very parts with high degrees of accuracy, as well as fine details or complex shapes. However, tolerances and deformations vary on the design, and depending on its geometry, we may also observe warping.

-

3D printing. Acrylic and polycarbonate is available as 3D printing filament and liquid resin, meaning both materials are compatible with various types of 3D printing.

-

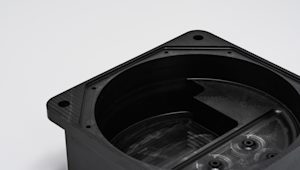

Injection molding. Both acrylic and polycarbonate can be injection molded, which is a great choice when making large batches of parts.

What industrial applications are suited for acrylic and polycarbonate?

Acrylic and polycarbonate are used in many similar industrial applications. However, because polycarbonate has better impact resistance, you will notice that the applications for which it is used tend to be more demanding.

-

Automotive. You can use polycarbonate to create parts like vehicle body components and headlight covers, while acrylic is used for interior applications like light covers and instrument panels.

-

Electronics. Polycarbonate is a good choice for housings or covers for sensitive electronic components, while acrylic is better for creating parts like display screens or light diffusers.

-

Construction. In construction, polycarbonate is often used to create roofing and glazing, while acrylic can be used to create windows, barriers, and signage.

-

Medical. Polycarbonate can be sterilized, making it a reasonable choice for medical applications like syringes and surgical instruments. Acrylic, on the other hand, could be used to create display cases and lab equipment.

-

Consumer goods. Polycarbonate is used for phone cases, eyeglass lenses, and water bottles. Acrylic is also widely used in the consumer good industry, for products like picture frames, aquariums, and cosmetic cases.

Produce custom PC or PMMA parts

Order custom parts using PC or PMMA. Just upload a CAD file to receive instant pricing and lead times. To get your project started, you can also read more about choosing the right materials for your application and our guide to plastics.

Frequently asked questions

Can polycarbonate be used in high-precision applications?

Yes, polycarbonate can be precisely machined and molded for high-precision components.

How does polycarbonate compare to acrylic in terms of flammability?

Polycarbonate is less flammable than acrylic, with better flame-retardant properties.

How does acrylic respond to UV exposure?

Acrylic is UV-resistant and does not yellow under prolonged exposure to sunlight.

What are the load-bearing capabilities of acrylic?

Acrylic has good tensile strength but lower impact resistance compared to polycarbonate.

How does acrylic's chemical resistance compare to polycarbonate?

Acrylic is more resistant to alkalis and some organic solvents, but less resistant to acids and alcohols than polycarbonate.