When the temperature rises, manufacturing materials don’t just get hotter, they creep, oxidize, expand, and slowly lose strength. That’s what changes fits, tolerances, and long-term reliability.

If you’re searching for materials for high-heat applications, you probably want to know what you can use, what it will survive, and what to watch out for.

This guide breaks down what counts as “high temperature,” the key properties to check, and common heat-resistant materials for CNC machining, 3D printing, and injection molding.

What counts as "high temperature"?

What counts as “high temperature” depends on the material. It’s any service temperature high enough to change strength, stiffness, dimensional stability, or chemical resistance in a way that affects function or safety.

As a quick rule of thumb:

-

Polymers: High temperature often starts around 150°C+. As you approach the polymer’s glass transition temperature (Tg), stiffness can drop quickly and creep risk rises.

-

Metals: High temperature is often 300°C+, where strength loss and long-term effects like creep become more important.

-

Very high heat: Above 600°C, oxidation and creep tend to guide material choice.

| Temperature band | Typical range | Common scenarios |

|---|---|---|

| Elevated temperature | 100–150 °C | Warm electronics housings, light under-hood exposure |

| High temperature | 150–300 °C | Continuous hot air, tooling near heat sources, many high-temp plastics |

| Very high temperature | 300–600 °C | Exhaust systems, hot manifolds, industrial furnaces |

| Extreme temperature | 600–1000 °C | Turbine hot-sections, high-temp fasteners, some nickel alloys |

| Ultra-high temperature | 1000 °C+ | Specialized superalloys, ceramics, thermal barrier systems |

Properties that matter most at high temperature

In high heat, failures are often slow, like creep, warping, and oxidation. Here are the core properties to check when selecting heat-resistant materials:

-

Strength retention: How much strength and stiffness the material keeps at your operating temperature.

-

Creep resistance: Whether it will slowly deform under constant load over time.

-

Oxidation and corrosion resistance: How well it holds up in hot air, moisture, fuels, or chemicals.

-

Thermal behavior: Thermal conductivity and coefficient of thermal expansion (CTE), especially for tight tolerances or multi-material assemblies.

-

Surface protection: If oxidation, wear, or corrosion is a risk, coatings and surface finishing services can extend part life.

-

Heat treatment / temper (metals): Temper condition can dramatically change high-temperature strength and stability.

Metals vs. polymers for high-heat applications

For most designs, the first big choice is whether you can use a high-temperature polymer or you need to move to metal. Polymers can work well in moderate heat, especially for lightweight, chemical-resistant parts, but as temperatures rise, metals usually dominate.

Key takeaway: Below ~300°C you still have viable polymer options. Above ~300°C, you’re usually choosing from metals for continuous service and load-bearing designs.

Metals for high-heat applications

Metals are the go-to materials for most high-temperature applications, offering excellent strength, thermal conductivity, and manufacturability through processes like CNC machining.

-

Aluminum: Great for weight and conductivity, but it loses strength quickly above ~150–200°C. For sustained heat or load, move to steel or titanium.

-

Stainless steels: The default for hot air and oxidation resistance.

-

Titanium alloys: A strong pick when weight matters, typically up to ~400°C for many applications.

-

Nickel superalloys: The go-to above ~700°C (and for high load/long exposure), common in aerospace and power generation.

| Material | Max continuous temp | Key advantages | Typical applications |

|---|---|---|---|

| Aluminum alloys | 150–200 °C | Lightweight, excellent thermal conductivity | Heat sinks, housings, moderate under-hood components |

| Copper alloys | 200–300 °C | Great thermal conductivity | Heat exchangers, thermal management |

| Titanium alloys | ~400 °C | High strength-to-weight ratio | Aerospace structures, hot hardware |

| Stainless steels (304/316/321) | 800 °C (oxidation resistance, not strength) | Good oxidation resistance, widely available | Exhaust hardware, food processing, chemical equipment |

| Tool steels | ~600 °C | High hardness and wear resistance (temp depends on grade/tempering) | Tooling, dies, hardened components |

| Nickel superalloys | 700–1200 °C | Exceptional strength retention and oxidation resistance | Turbine engines, combustors, power generation, high-temp fasteners |

| Cobalt superalloys | 800–1100 °C | Excellent hot strength and oxidation resistance | Turbine vanes, hot-section components |

High-temperature polymers and polymer composites

Advanced engineering polymers can sometimes replace metal parts below ~300°C, especially when you need weight savings, chemical resistance, or electrical insulation.

-

PEEK / PAI: Top picks for heat + load (best polymer strength and creep resistance).

-

PEI (Ultem): Great all-rounder for dimensional stability and flame resistance.

-

PPSU: Best for steam and hot-water exposure with strong toughness.

-

PTFE: Low friction and chemical resistance, but not structural under load.

-

Carbon-filled grades: Improve stiffness and dimensional stability, with a tradeoff in brittleness and tool wear.

If you want a deeper overview of selection criteria, check out our guide to heat-resistant plastics.

| Material | Max continuous temp | Tg / melt point | Key advantages | Typical applications |

|---|---|---|---|---|

| Polycarbonate | ~120 °C | ~150 °C | Impact resistance, transparency, dimensional stability | Safety equipment, optical applications, electronics |

| PSU/PESU (Polysulfone/Polyethersulfone) | 150–180 °C | ~185–230 °C | Hydrolytic stability, steam resistance, transparency | Medical devices, food processing, sterilizable components |

| PEI (Ultem) | 170 °C | ~217 °C | Dimensional stability, flame resistance, some grades transparent | Aircraft interiors, medical devices, electronics |

| PPS | 200 °C | ~90 °C | Chemical resistance, inherent flame retardancy | Automotive fuel systems, electrical connectors, pump housings |

| PPSU (Polyphenylsulfone) | 180–200 °C | ~220 °C | Steam + hot-water resistance, tough, hydrolytically stable | Medical devices, food processing, sterilizable components |

| PEEK (Polyetheretherketone) | 250 °C | ~143 °C | Excellent mechanical properties, chemical resistance, biocompatible | Aerospace structures, medical implants, under-hood automotive |

| PAI (Polyamide-imide) | 260 °C | ~280 °C | Exceptional wear resistance, creep resistance | Bushings, bearings, seals in high-temp environments |

| PTFE (Teflon) | 260 °C | Melt point ~327 °C | Chemical resistance, low friction, non-stick | Seals, gaskets, coatings (limited structural use) |

| CF-PEEK / CF-PEI | 250 °C+ | Similar to base polymer | Enhanced strength, stiffness, dimensional stability | Aerospace structural parts, industrial machinery |

Continuous use temperature varies by grade and environment. Use as a screening metric only.

Coatings and surface finishes for high temperatures

Even the best high-heat materials often benefit from extra surface protection—especially in hot air, corrosive environments, or under repeated thermal cycling.

-

Thermal barrier coatings (TBCs): Ceramic coatings can insulate the surface and help metal substrates run cooler (often by ~100–200°C at the surface).

-

Anodizing: Best for aluminum parts in moderate heat. It improves corrosion resistance and surface hardness, and can slightly improve oxidation resistance (often used around ~150–250°C).

-

High-temperature paints and powder coatings: Silicone- or ceramic-filled coatings can protect steel and other metals up to ~600°C, reducing oxidation and improving heat radiation.

-

Electroless nickel plating: Adds uniform corrosion and wear resistance, with some high-temperature variants rated to ~400°C.

Have a custom request? Email networksales@protolabs.com.

Manufacturing processes for high-heat materials

High-temperature material selection is also highly dependent on what you can reliably manufacture. Here's how high-heat materials show up across processes:

-

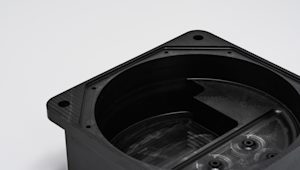

CNC machining: Best for high-temperature metals (stainless steel, titanium, nickel alloys) and high-performance plastics (PEEK, PEI, PPS, PPSU) when you need tight tolerances and strong mechanical performance.

-

Injection molding: Best for high-volume production in high-temperature thermoplastics like PPS, PEI, PEEK, and CF-filled variants.

-

3D printing: Useful for complex geometry and rapid iteration in heat-resistant polymers (commonly PEI/Ultem and some PEEK systems).

If your process is already fixed, confirm material availability early using the materials overview.

Choosing the right material for your application

Temperature narrows the shortlist, but it doesn’t pick the final material. Your environment (hot air, steam, chemicals), time at temperature (short bursts vs. continuous use), and mechanical load (creep risk) all shift the answer. Always validate final limits with datasheets for your specific grade and conditions.

| Service temperature | Start with | Why it works |

|---|---|---|

| ≤200 °C | PEI, PPS, PSU/PESU/PPSU | Stable, chemical resistant; PSU/PESU/PPSU for steam. |

| 200–300 °C | PEEK, PAI, CF-filled variants | Best for heat and load; CF for stiffness. |

| 300–600 °C | Stainless steels, tool steels, titanium | Metals dominate based on oxidation, weight, wear. |

| ≥600 °C | Nickel superalloys, high-temp stainless (309/310) | Nickel for load/long exposure; 309/310 near 600 °C. |

Where to learn more

Explore the materials overview and knowledge base for more on heat treatments and tempers, heat-resistant plastics, and injection molding materials.

Order custom parts for high temperatures

Ready to start your next hot project? Get an instant quote on high-temperature parts that can handle the heat.

Frequently asked questions

What is the best material for high-temperature applications?

It depends on temperature. High-performance polymers like PEEK work up to ~250°C. Stainless steels handle ~300–600°C. Nickel superalloys are often used above ~700°C.

Can plastic parts withstand high temperatures?

Yes, high-performance plastics like PEEK and PEI can handle ~150–260°C continuously, while standard plastics like ABS are often limited to ~80–120°C.

What’s creep, and why does it matter at high temperatures?

Creep is slow deformation under constant load, and it’s a common long-term failure mode in hot environments.

Should I prioritize oxidation resistance or corrosion resistance?

If the part sees hot air, prioritize oxidation resistance. If it sees chemicals, prioritize corrosion resistance.