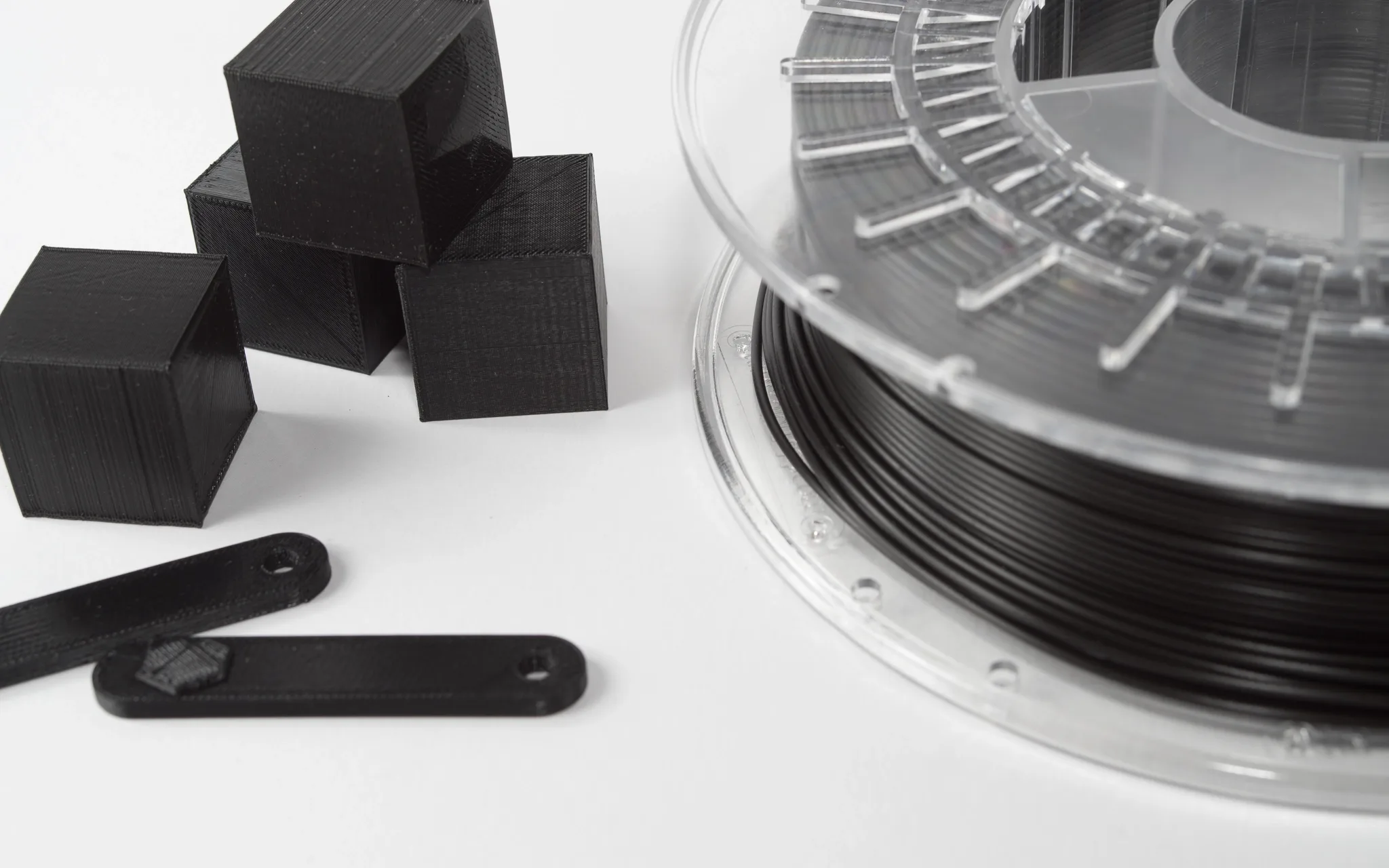

PLA and ABS are the two most common materials for prototyping FDM 3D printing (along with PETG). Both are thermoplastics, so the filament softens when heated and returns to a solid when cooled. FDM printers melt and extrude PLA or ABS through a nozzle to build parts layer by layer.

While both are used for FDM they have key differences that make each better suited to specific applications. This article covers the main differences engineers should consider.

We also have a Youtube explainer video that compares PLA and ABS filaments.

Want to compare pricing for PLA and ABS?

What is PLA? Printing with polylactic acid

PLA (polylactic acid) is a thermoplastic derived from renewable sources such as cornstarch or sugarcane. Biodegradable under the right conditions, PLA is a widely used bioplastic for applications ranging from plastic cups to medical implants.

For FDM 3D printing, PLA is cost efficient and delivers good surface quality. It is easy to print and has higher stiffness than ABS and materials like nylon, but it does not handle high temperatures or significant stress well. PLA can be stronger than ABS and some nylon grades, but it offers limited heat and chemical resistance.

What is ABS? Printing with Acrylonitrile Butadiene Styrene

ABS (acrylonitrile butadiene styrene) is a common thermoplastic used in FDM 3D printing and widely used in injection molding. Typical applications include toys such as LEGO bricks, housings for electronics, automotive components, and household appliances.

ABS is tough and impact resistant, with mechanical properties that generally exceed PLA while being lighter and more durable. The tradeoff is more challenging printability and higher processing temperatures. ABS deflects heat more effectively than PLA, but it is not known for high heat resistance. During printing, ABS can produce strong odors.

What’s the difference between PLA and ABS?

PLA and ABS differ in tensile strength, density, and typical applications. The table below compares the key material properties of PLA and ABS filaments.

| Properties* | ABS | PLA |

|---|---|---|

| Tensile Strength** | 27 MPa | 37 MPa |

| Elongation | 3.5 - 50% | 6% |

| Flexural Modulus | 2.1 - 7.6 GPa | 4 GPa |

| Density | 1.0 - 1.4 g/cm3 | 1.3 g/cm3 |

| Melting Point | 200 ℃ | 173 ℃ |

| Biodegradable | No | Yes, under the correct conditions |

| Glass Transition Temperature | 105 ℃ | 60 ℃ |

| Spool Price*** (1kg, 1.75mm, black) | $USD 21.99 | $USD 22.99 |

| Common Products | LEGO, electronic housings | Cups, plastic bags, cutlery |

What is the part accuracy of PLA and ABS?

Dimensional accuracy in FDM depends on machine calibration, process control, and part geometry. PLA and ABS typically achieve about 0.8 mm feature resolution, with minimum feature sizes around 1.2 mm. For connecting or interlocking parts, a typical guideline is 0.5 mm clearance and a minimum wall thickness of 1 to 2 mm to maintain strength across walls.

Because PLA prints at lower temperatures, it is generally easier to process with less risk of warping when cooled correctly. PLA also supports sharper corners and finer features than ABS.

Want to improve your 3D printing design skills?

How strong are PLA and ABS parts?

PLA and ABS have similar tensile strengths, which makes both suitable for many prototyping applications. Engineers often select ABS for its improved ductility compared to PLA. ABS offers higher flexural strength and greater elongation at break, which supports some end-use applications. PLA is commonly used for rapid prototyping when form is more important than function.

In general, PLA is a good choice when parts are not exposed to significant mechanical loads, UV radiation, or elevated temperatures. ABS is better suited to industrial use and withstands physical strain more effectively than PLA.

How fast can you print with PLA and ABS?

PLA and ABS generally print at similar speeds, so machine speed settings often remain unchanged when switching between these materials. For PLA, 60 mm/s is a common baseline, though print speeds above 150 mm/s are reported in some setups. ABS typically runs at the same speed range, with 40 to 60 mm/s providing more consistent results.

Surface finishes and post-processing for PLA and ABS

FDM parts have visible layer lines regardless of material. PLA often yields a glossier finish, while ABS tends to appear more matte. Acetone vapor smoothing is commonly used to give ABS a glossy finish. Sanding and secondary machining are viable for ABS, and PLA can also be sanded and machined with additional care. For parts where cosmetic quality is critical, SLA 3D printing is often selected.

Want to explore all the options for FDM post-processing?

How heat resistant are PLA and ABS?

For higher temperature applications, ABS is preferred over PLA. ABS has a glass transition temperature of about 105°C, while PLA is around 60°C. As PLA approaches 60°C, it can lose structural integrity and may droop or deform, especially under load.

Are PLA and ABS biodegradable?

PLA remains stable under normal atmospheric conditions, but it can biodegrade in industrial composting within about 50 days and in water within about 48 months. ABS is not biodegradable, but it is recyclable. For food service applications, material safety must be confirmed with the filament supplier and applicable regulations.

Frequently asked questions

When should you use PLA?

PLA is a strong choice when high-quality aesthetics are required. Its lower printing temperature supports fine details and consistent surface finish, making it suitable for visual prototypes and parts that are not exposed to elevated temperatures or high loads.

When should you use ABS?

ABS is suited for applications that require strength, ductility, machinability, and thermal stability. Its durability makes it a good option for prototyping, low-stress end-use components, and other practical applications. ABS is more prone to warping than PLA.

How strong are PLA and ABS?

PLA and ABS have similar tensile strength. Engineers often select ABS for its improved ductility. ABS typically offers higher flexural strength and greater elongation at break than PLA.

Are PLA and ABS flexible?

PLA and ABS are not flexible filament materials like TPU. ABS is generally less brittle and more impact resistant than PLA.

How long do PLA and ABS last?

PLA and ABS parts can last for decades when they are not used in heavy load bearing applications.