CNC machining produces parts with tight tolerances and fine detail from a wide range of metals and plastics. Because material is removed rather than added, machined parts often show visible tool marks. Surface finishing reduces those tool marks, improves functionality, and enhances appearance.

Surface finishing applies post-processing to improve surface roughness, appearance, and wear resistance of CNC machined metal parts. When the finish matches the application, it enhances both function and aesthetics.

This article outlines the most common surface finishes for metal CNC parts to help engineers select the best option for outsourced production.

Did you know we offer local sourcing for CNC machining?

What CNC machining surface finishes do we offer?

Below are the most common surface finishes available on our platform for metal parts.

| As machined | As-machined parts show minor visible tool marks. The standard surface roughness (Ra) is 3.2 μm, with tighter options of 1.6, 0.8, and 0.4 μm available. |

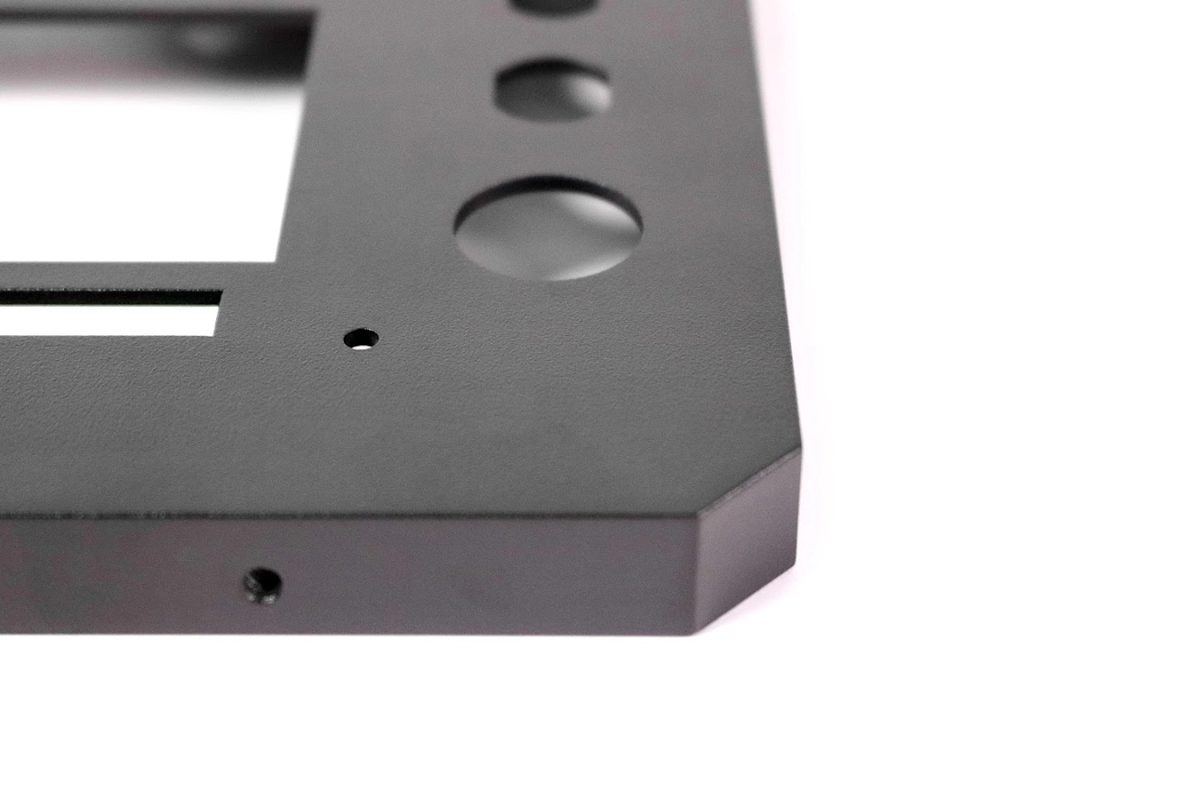

| Bead Blasting | Bead blasted parts have a matte finish with a fine texture. This finish is primarily used to improve a part's visual appearance. |

| Anodizing Type II (clear or color) | Type II anodizing creates a corrosion-resistant oxide layer on the part surface. Available for aluminum and titanium, this finish can be dyed in a range of colors. |

| Anodizing Type III (hardcoat) | Type III anodizing creates a thicker, wear- and corrosion-resistant oxide layer that provides greater protection than Type II. Available for aluminum and titanium, this finish can also be dyed in a range of colors. |

| Powder coating | Type III anodizing creates a thicker, wear- and corrosion-resistant oxide layer that provides greater protection than Type II. Available for aluminum and titanium, this finish can also be dyed in a range of colors. |

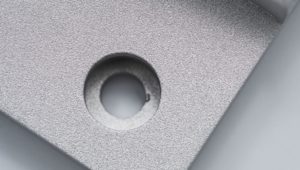

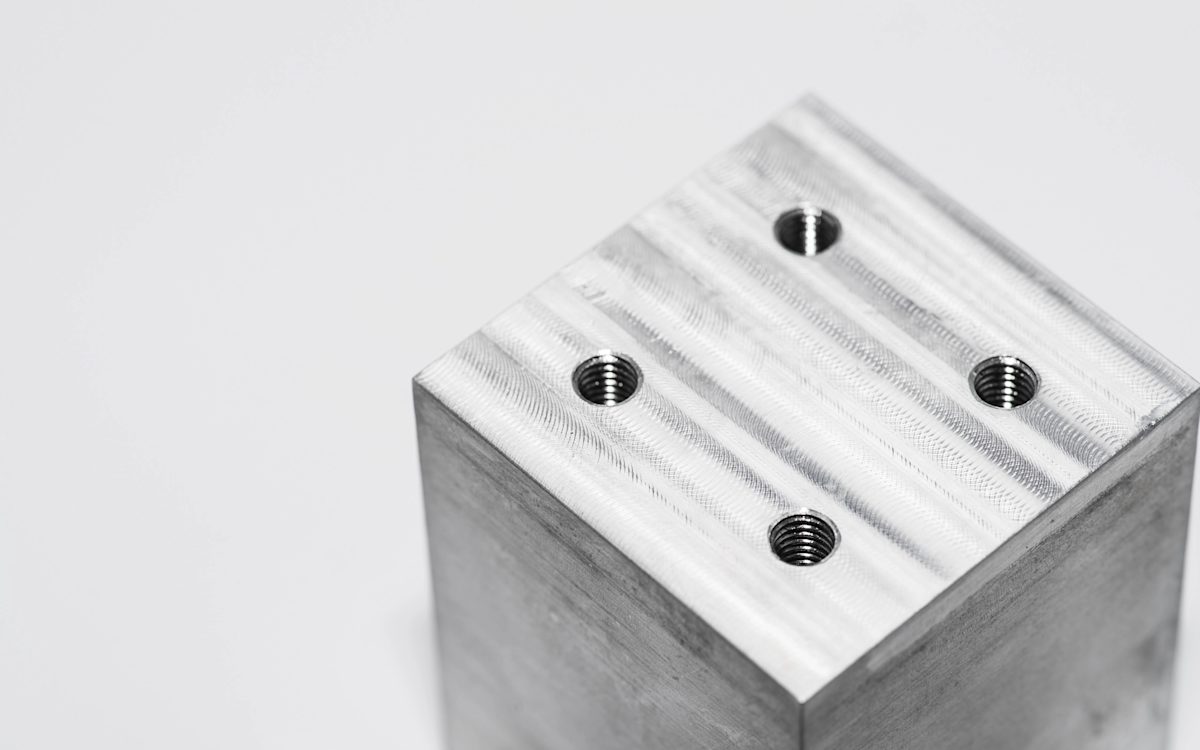

Surface finishes explained: As machined

All CNC machined parts show marks that follow the cutting tool path. Surface quality is expressed as average surface roughness, Ra, which measures the average deviation of the machined profile from an ideal surface.

The standard as-machined Ra is 3.2 μm (125 μin). A finishing cutting pass can reduce Ra to 1.6, 0.8, or 0.4 μm (63, 32, or 16 μin). Tighter Ra values increase part cost because they require additional machining steps and stricter quality control.

Smoothing or polishing can improve appearance by lowering Ra, but these processes remove material and can affect dimensional tolerances.

Pros

Cons

| Finish | ★ ★ ☆ ☆ ☆ |

| Tolerances | ★ ★ ★ ★ ★ |

| Protection | ★ ☆ ☆ ☆ ☆ |

| Cost | $ |

| Suitable for | Any material |

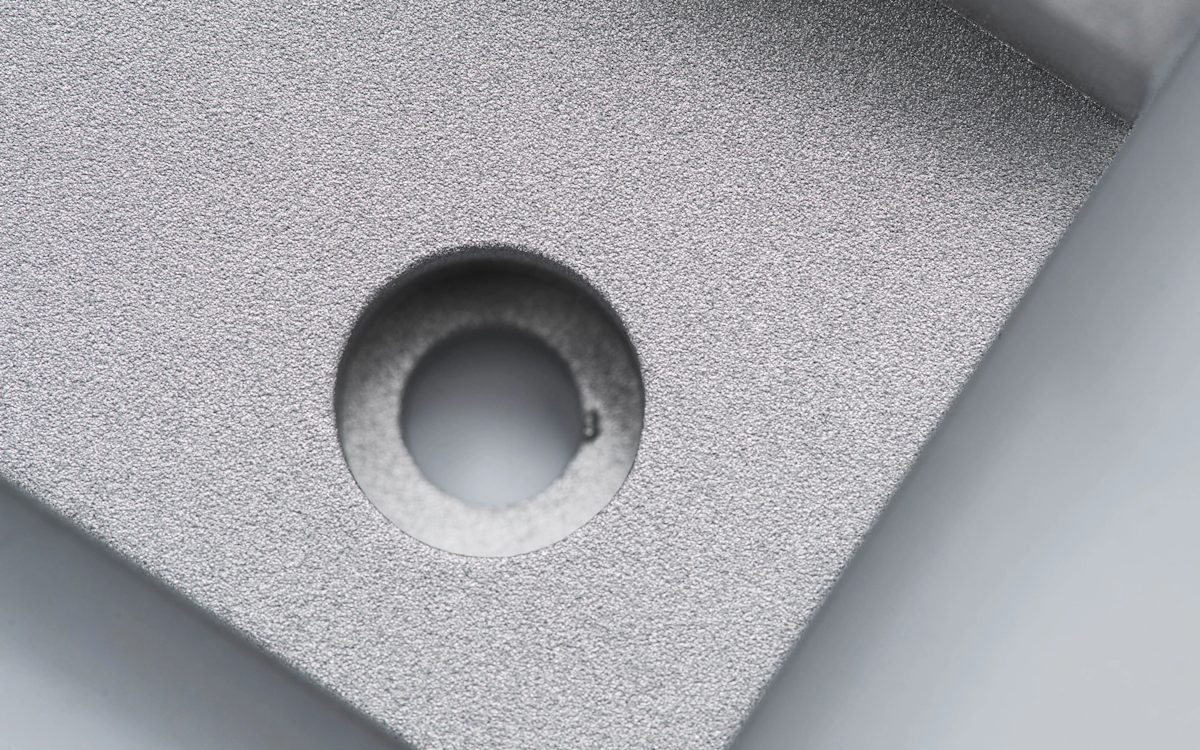

Surface finishes explained: Bead blasting

Bead blasting produces a uniform matte or satin finish and reduces visible tool marks. The process uses a stream of glass beads propelled by pressurized air to remove small amounts of material and smooth the part surface. Critical features, such as holes, can be masked to prevent dimensional change.

Bead blasting is primarily used for aesthetics. It is a manual operation, so the final appearance depends in part on operator skill. The main process variables are air pressure and bead size. Glass beads range from coarse to very fine, similar to sandpaper grades. Protolabs Network generally uses a #120 grit for bead blasting.

Pros

Cons

| Finish | ★ ★ ★ ☆ ☆ |

| Tolerances | ★ ★ ★ ☆ ☆ |

| Protection | ★ ☆ ☆ ☆ ☆ |

| Cost | $$ |

| Suitable for | Any material |

Surface finishes explained: anodizing (Type II and Type III)

Anodizing forms a thin ceramic oxide layer on metal parts to protect against corrosion and wear. The anodic coating is nonconductive, and type III produces a thicker, harder layer than type II. Anodizing is compatible with aluminum and titanium only. Coatings can be dyed for color.

With type II and type III anodizing, the part is submerged in a diluted sulfuric acid solution and a voltage is applied between the part and a cathode. An electrochemical reaction converts the exposed surface material into hard aluminum or titanium oxide. Areas that require tight dimensions or electrical conductivity, such as threaded holes, can be masked to prevent anodizing. Dyeing is done before sealing to add color.

By varying current, anodizing time, solution concentration, and temperature, manufacturers control coating thickness and density to meet engineering requirements.

What is Type II (clear or color) anodizing?

Type II anodizing, also called standard or decorative anodizing, produces oxide coatings typically in the 4–12 µm range depending on color. Black-dyed parts commonly fall in the 8–12 µm range, while clear (undyed) coatings are usually 4–8 µm.

Type II improves surface smoothness and provides good corrosion resistance with limited wear resistance.

What is Type III (hardcoat) anodizing?

Type III anodizing, also called hardcoat anodizing, produces much thicker ceramic oxide layers. Typical hardcoat thickness is about 50 µm unless another thickness is specified, and coatings can be produced up to 125 µm.

Type III delivers high density and superior corrosion and wear resistance for functional applications. It requires tighter process control than Type II, including higher current density and a solution temperature maintained near 0 °C, which increases process cost.

Pro-tip for anodizing

The anodic coating grows outward and inward from the original surface. For example, a 50 µm coating will extend about 25 µm above the original surface and remove about 25 µm below it. A cylinder 1.00 mm in diameter before anodizing will measure about 1.05 mm after a 50 µm coating. See MIL-A-8625 for detailed specifications.

Pros

Cons

| Finish | ★ ★ ★ ★ ★ |

| Tolerances | ★ ★ ★ ★ ☆ |

| Protection | ★ ★ ★ ☆ ☆ (Type II); ★ ★ ★ ★ ☆ (Type III) |

| Cost | $$$ (Type II); $$$$ (Type III) |

| Suitable for | Aluminum & titanium |

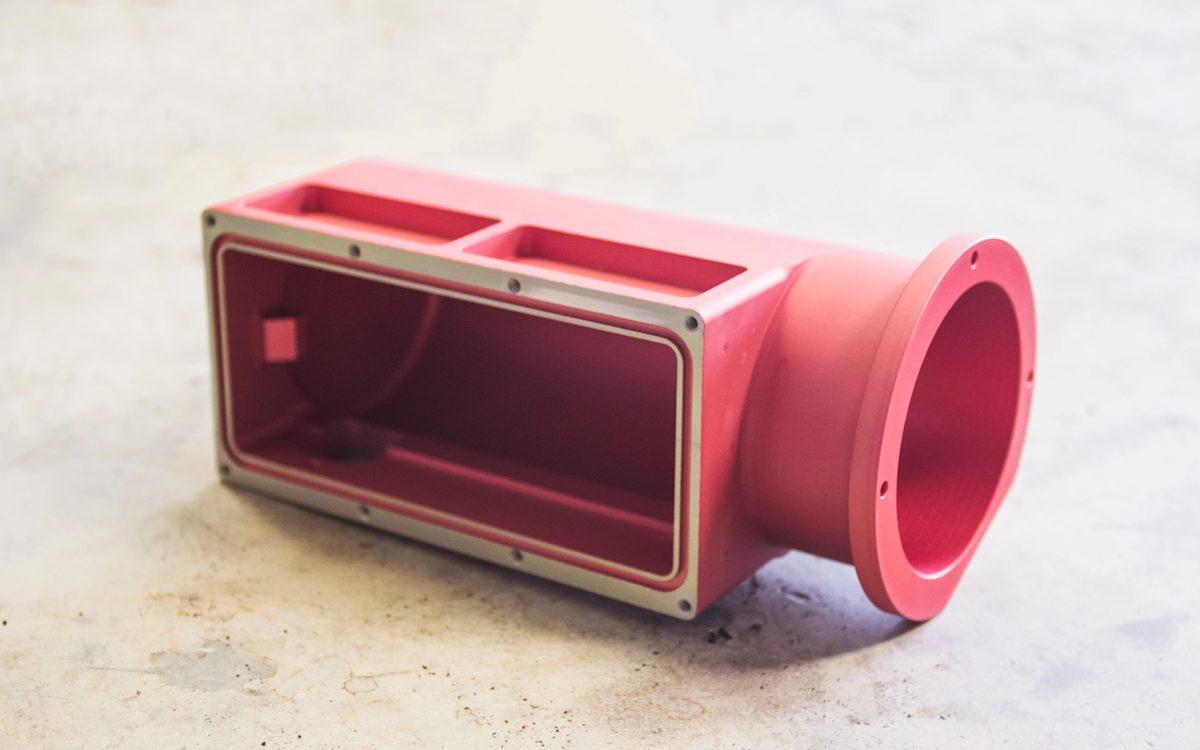

Surface finishes explained: Powder coating

Powder coating adds a thin, protective polymer layer to part surfaces. It is a durable, wear and corrosion resistant finish that can be applied to any metal and is often combined with bead blasting to produce a uniform, smooth appearance.

Powder coating process is similar to spray painting but uses a dry powder instead of a liquid. Parts may receive an optional phosphate or chromate primer to improve corrosion resistance. The dry powder is applied with an electrostatic spray gun and the parts are cured in an oven, typically at about 200 degrees Celsius.

Multiple layers can be applied to increase coating thickness. Typical thickness ranges from about 18 μm to 72 μm. A wide range of colors is available.

Pros

Cons

| Finish | ★ ★ ★ ★ ★ |

| Tolerances | ★ ★ ★ ☆ ☆ |

| Protection | ★ ★ ★ ☆ ☆ |

| Cost | $$$ |

| Suitable for | Any material that can survive the thermal curing process |

What are Protolabs Network top tips & tricks for choosing surface finishes for CNC machining?

Selecting the right surface finish depends on how well the finish properties match the part requirements and application. Each finish has trade offs, so decisions should be based on function and appearance rather than preference alone.

Functional and aesthetic requirements should be defined separately. Surfaces that must resist wear, corrosion, or carry electrical current typically need different treatments than cosmetic faces. Consider how the finished part will mate with adjoining components and whether sealing, conductivity, or tight tolerances are required.

Friction and wear are key factors. Parts exposed to repeated contact, sliding, or abrasion usually need harder, thicker coatings. Cosmetic finishes such as bead blasting can improve appearance but provide limited protection unless combined with an anodize or coating.

The operating environment affects finish choice. Outdoor exposure, salt spray, high temperature, and UV light can require more robust finishes than indoor use. Dimensional change from coatings and masking needs for critical features should be accounted for during design and specified on drawings.

Best practices per surface finish

-

Bead blasting: suitable when dimensional tolerances are not critical. Provides a uniform matte texture to improve appearance.

-

Anodizing (type II): appropriate for aluminum and titanium when corrosion resistance and a cosmetic finish are required. Available clear or dyed.

-

Anodizing (type III): suited to functional parts that require high wear resistance and surface hardness. Used where durability is a priority.

-

Powder coating: recommended for applications needing high impact resistance and a wide color range. Applicable to most metals and an alternative when anodizing is not suitable.

Need CNC parts machined fast? We've got 5 day lead times

Frequently asked questions

What is surface finishing?

Surface finishing is the final stage of CNC machining that improves part appearance and performance. Finishing removes tool marks and minor defects, enhances corrosion and wear resistance, and can adjust electrical conductivity or surface texture. Finishes can affect dimensions and tolerances, so specify critical surfaces and any masking requirements when ordering parts.

What is the purpose of surface finishing?

Surface finishing protects parts from wear, corrosion, and chemical attack while improving their appearance. The appropriate finish can also enhance functionality by increasing wear resistance, controlling friction, sealing pores, or adjusting electrical properties. Critical surfaces and tolerances should be specified so finishing is applied where required without compromising fit or function.

What are the different types of surface finishes?

Protolabs Network offers a range of surface finishes for metal parts, including bead blasting, anodizing type II and type III, powder coating, brushed and electropolished, and brushing. Other finishes are available depending on material and application. Specify required areas and tolerances when ordering to ensure the correct finish is applied for your engineered parts.

What’s the difference between surface finishing and surface roughness?

Surface finishing is any post-processing applied to a part after machining to change its appearance or performance. Surface roughness is a way to quantify the small-scale irregularities on a surface. The Ra parameter represents the average of all surface heights measured across a given surface area.

What preparation is needed before applying surface finishes?

There are often steps between removing a part from the machine and applying a surface finish. For example, masking may be required to protect specific surfaces or holes because some finishes add material thickness. Added thickness can interfere with threaded holes and tight tolerances, so critical areas should be identified and protected before finishing.

Can you combine several surface finishes?

Yes. Multiple surface finishes are often combined to achieve both the required appearance and functional properties. For example, bead blasting before anodizing produces a uniform matte look and then adds corrosion and wear resistance. Sequence, masking, and dimensional allowances should be considered so the final part meets tolerance and performance requirements.

Is there an alternative to anodizing for materials other than aluminum and titanium?

Yes. For stainless steels and tool steels, a common alternative is black oxide, which applies a thin iron oxide layer to the surface. The coating reduces light reflection and, when sealed with oil or wax, improves corrosion resistance and lowers friction. Black oxide is suitable for ferrous materials where anodizing is not compatible.