Delrin is an engineering thermoplastic that offers low friction, high stiffness, and exceptional dimensional stability. It enables the production of highly precise parts because of its high strength and wide operating temperature range (−40 to 120 degrees Celsius). Delrin also delivers strong mechanical performance and is tougher than ABS.

This article examines the material properties of Delrin and offers practical tips for working with this robust engineering thermoplastic. Whether planning to CNC machine, injection mold, or 3D print custom parts, this resource explains what Delrin is made of and when to use it.

Did you know we offer local sourcing for CNC machining?

How is Delrin made?

Delrin, or POM-H (homopolymer acetal), is part of the POM family, which also includes copolymer acetal (POM-C). The polymer chemistry behind Delrin was first identified by German chemist Hermann Staudinger in 1920. DuPont later developed and commercialized Delrin, producing it from 1956.

Delrin is made by distilling hydrocarbons into fractions and combining those fractions with catalysts through polymerization to form the finished plastic. The Delrin name refers specifically to the acetal homopolymer first manufactured by DuPont.

How is Delrin used? What can you make with Delrin?

Delrin is preferred by many machinists because it machines easily on 3- and 5-axis centers, similar to metal parts. It is also suitable for 3D printing and injection molding, which makes it a versatile choice for a wide range of applications.

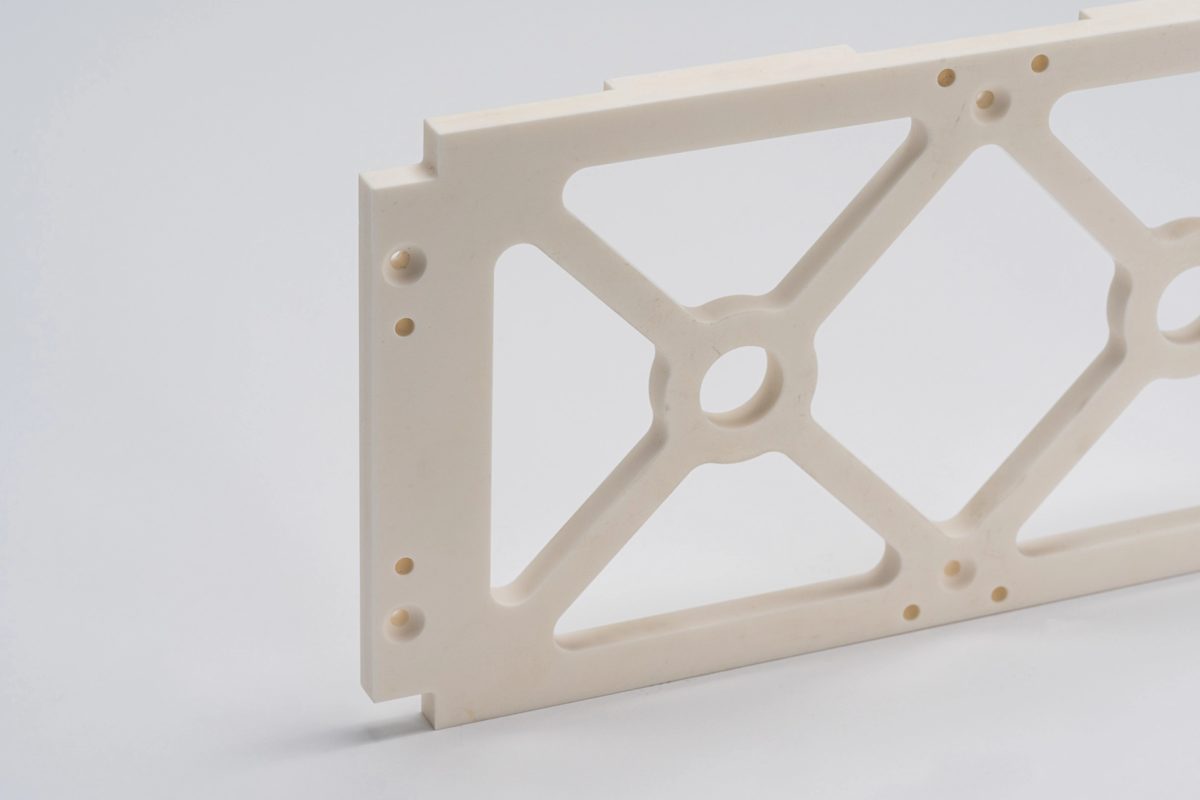

Delrin components are common in automotive and consumer electronics, and in any sector that requires high performance engineering parts. Typical uses include gear wheels, housings, screws, nuts, and pump components.

Electrical engineering parts such as connectors, covers, and insulators are frequently made from Delrin. It is also used for vehicle components like door locks and articulated shells, and in medical devices such as insulin pens and metered dose inhalers. Delrin is often selected as a plastic replacement for metal parts.

What are the benefits of making parts with Delrin?

Delrin offers a combination of properties that make it a strong choice compared with many plastics and some metals. High strength and stiffness allow parts to carry heavy loads while retaining dimensional stability through humidity and temperature changes.

Delrin also shows excellent resistance to impact, creep, fuels, and solvents, so it is suitable for petrochemical environments and other demanding conditions.

These properties make Delrin a good option for industrial, automotive, aerospace, energy, healthcare, and consumer applications. Common uses include pump and valve components, kitchen appliances, water management controls, sports equipment, and food containers. Delrin is also frequently used to replace metal parts.

From a manufacturing perspective, Delrin machines well. It can be cut into a wide range of geometries with standard tools and is well suited to injection molding and extrusion.

How do you assemble Delrin parts?

Delrin parts can be assembled with self-tapping screws, snap fits, and press fits for removable joints. Welding, adhesives, and riveting provide permanent assembly.

For prototypes or small runs, adhesives are an option, but they typically lack the strength required for end-use performance. Bonded joints are recommended when performance is critical.

Clean and degrease mating surfaces with sandpaper or appropriate chemicals to improve assembly results.

What’s the difference between Delrin and acetal?

There are two main variants of POM: POM-C (copolymer) and POM-H (homopolymer). Delrin is the commercial name for POM-H, while POM-C is commonly referred to as acetal. A key difference is melting point: POM-C softens around 160 to 175 degrees Celsius, while POM-H melts between 172 and 184 degrees Celsius.

Overall, POM-H offers superior mechanical and physical properties compared with POM-C, making it better suited for applications requiring high abrasion resistance and a low coefficient of friction. POM-C is not as strong or as stiff as Delrin, but it is easier to process and performs well in low‑friction applications.

What are the material properties of Delrin?

Delrin is a high-performance engineering thermoplastic with several notable properties:

-

Excellent dimensional and geometric stability

-

Reliable machinability

-

Resistance to wear and fatigue

-

Good heat and chemical resistances

-

Shiny surface and opaque white color (natural form)

In many cases Delrin can replace metals and be used in 3D printing. These properties stem from its chemical composition and high degree of crystallinity. Some of Delrin’s chemical benefits include:

-

Toughness at lower temperatures (as low as -40 degrees Celcius)

-

High mechanical strength

-

High rigidity

-

Endurance against fatigue

-

Impact and moisture resistance

-

Ease of fabrication

-

Insulating characteristics for electrical use

-

Solvent and neutral chemical resistance

However, while Delrin is more resistant to rapid failure from exposure to organic compounds than other plastics, it is susceptible to strong acids, strong bases, and hot water or steam.

Mechanical properties of Delrin

-

Ultimate tensile strength: 60 - 89.6 MPa

-

Yield strength: 48.6 - 72.4 MPa

-

Young's modulus (modulus of elasticity): 2.5 - 4 GPa

-

Elongation at break: 15 - 75%

-

Hardness: 14.6 - 24.8 HV

Thermal properties of Delrin

-

Maximum service temperature: 76.9 - 96.9 degrees Celcius

-

Thermal expansion coefficient: 75.7 - 202 10^-6 / degrees Celcius

-

Thermal conductivity: 0.221 - 0.35 W / (m - degrees Celcius)

Physical properties of Delrin

-

UV resistance: Poor

Electrical properties of Delrin

-

ESD Safety: Yes

Delrin can be machined with standard shop equipment such as drilling, milling, turning, threading, sawing, and tapping. Its material properties should be considered during machining: lower stiffness requires support for thin walls to prevent deflection, and lower thermal conductivity and melting point require minimizing heat input.

What’s the right surface finishing for Delrin?

Delrin parts are typically finished one of two ways depending on cosmetic needs and function. As-machined parts are usually acceptable but will show machining marks and a slightly rough surface. Bead blasting provides a uniform matte finish and can improve surface durability.

Several surface customization options are available for Delrin parts, including hot stamping, silk screen printing, painting, laser marking, metalizing, and pad printing.

Painted Delrin parts can be baked at temperatures up to 160 degrees Celsius. Surfaces can also be metalized with copper, chrome, or aluminum coatings to improve appearance and durability. Delrin parts accept laser marking and can be pretreated with mildly acidic solutions to improve adhesion.

How do geometric tolerances behave for large Delrin parts?

Delrin machines easily and is dimensionally stable, which supports tight tolerances. However, large parts can exhibit shrinkage of about ±0.05 mm.

How much does it cost to machine Delrin parts?

Delrin is among the most machinable plastics, which makes it more expensive than many alternatives but often worth the cost. It retains its shape during machining and is less likely to break because of its high rigidity.

What are the drawbacks of Delrin?

While Delrin is a robust material for many applications, it has drawbacks. It is difficult to bond because many adhesives and solvent-based glues do not properly dissolve its surface. Delrin is also flammable at elevated temperatures and can deform during machining if temperatures are not controlled.

Are there design restrictions for Delrin parts?

Delrin follows many common design rules that apply to engineering plastics. There are few material-specific restrictions, but standard best practices remain important to maintain tight tolerances and avoid deformation or fracture. Pay attention to wall thickness, support for thin features, thermal management during machining, and appropriate fillets at stress concentrations.

When designing parts for CNC machining, specify internal radii at corners rather than 90 degree angles. Milling cutters are cylindrical and cannot produce sharp internal corners without extra tooling or operations. Using radii reduces machining time and cost and simplifies production for machinists.

Avoid tight tolerances unless required. Not every component needs close tolerances, and specifying only the critical dimensions reduces cost and machining time.

Avoid thin walls and deep cavities in your designs. Thin walls increase machining time and can cause part damage during production. These features may require specialized machines, which raises cost. Keep thread depth to less than three times the hole diameter, since deeper threading increases machining time and cost.

Ready to start producing custom Delrin parts?

See if Delrin's right for your design Upload a CAD file for a free, instant quote

Frequently asked questions

Is Delrin plastic hard or soft?

Delrin is slightly harder than other acetal (POM) plastics.

How durable is Delrin?

Delrin is a durable, high-strength material suited to a range of applications. It performs well in wet environments and is a good option for thin, lightweight components. Delrin resists fatigue and impact and is unlikely to suffer permanent deformation.

What materials are similar to Delrin in terms of strength?

Nylon is similar to Delrin in strength, durability, and wear resistance. Both materials resist UV exposure and many chemicals and have a low coefficient of friction.

Nylon is generally the better choice for 3D printing, with many grades available. It is better suited to higher temperature applications than Delrin, while Delrin outperforms Nylon in moist or damp environments.

Is Delrin brittle?

Delrin can become brittle at low temperatures. Account for this when specifying part geometry and wall thickness.

How resistant is Delrin?

Delrin offers strong resistance to chemicals and wear, but it is not suited to high-temperature applications and will degrade if exposed to excessive heat.

Is Delrin a good substitute for metal?

Delrin can substitute for metal in many applications unless the specific strength or temperature properties of steel are required.

What’s the minimum dimension achievable with Delrin?

Delrin parts can have a minimum wall thickness of 0.8 mm (0.03 in). This may vary depending on the ratio of wall thickness to the part’s planar dimension. The minimum machining tolerance for Delrin is 0.25 mm (0.01 in). As nominal dimensions increase, achievable tolerances generally become looser.

How thin can walls be for Delrin parts?

Typically the minimum wall thickness should be at least 1 mm (0.039 in). For more robust strength, 2 mm (0.079 in) is recommended. For rigid walls, specify 2.5 mm (0.098 in).

What are the maximum working temperatures allowed for Delrin parts?

Delrin parts have a working temperature range of −40 degrees Celsius to 120 degrees Celsius.