Design for manufacturing or manufacturability (DFM) refers to an engineering method of creating a part or tool with a design-first focus, enabling a final product that is more effective and cheaper to produce. Taking a DFM approach enables engineers and designers to create, iterate, simplify and optimize parts before they are made, making the entire manufacturing process more efficient.

Ideally, the DFM process engages all stakeholders of a particular project, including engineers and designers, as well as manufacturers, material suppliers and any other manufacturing-related party that has a vested interest in a successful outcome.

Let’s explore how DFM works and how you can get the most out of the process.

Is your design ready for our platform's DFM analysis?

How does design for manufacturability (DFM) work?

The design for manufacturability (DFM) process works by examining five key principles: process, design, material, environment and compliance and testing. This enables designers and engineers to create custom components that are easier and more cost-efficient to manufacture.

Process

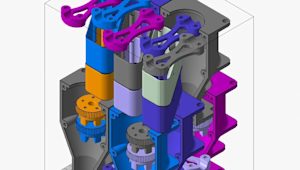

For DFM to be most effective, you must be sure that you’re using the right manufacturing process for any given project. Are you looking to create a high-volume batch of a certain part? Perhaps injection molding is your best option. On the other hand, low-volume, highly detailed parts may be most successfully achieved with a 3D printing process such as Multi Jet Fusion (MJF) or selective laser sintering (SLS).

The manufacturing process you choose will have a great effect on the final cost and efficiency of your project, so be sure to factor in details, such as materials needed, part quantity and properties of the parts or tools that will be created to help you choose the one that best fits your needs.

Design

Once you have chosen a manufacturing process, you can begin designing the actual part you will produce. It’s important, however, to consider the principles related to your particular manufacturing process – think wall thickness, surface details, texture or transitions.

It’s also important to note that, as a rule, DFM operates on a “the simpler, the better” philosophy. Obviously, not every design can be extremely simple, but the more complex a design, the riskier it becomes to produce. Some designs may fail in the manufacturing process, or be so complex that your overall costs get significantly higher.

Choosing the right design software is also integral to the success of your part. For example, if you are designing a part for sheet metal fabrication, but don’t use software specific to that technology, your design may cause errors in Protolabs Network's auto-pricing process.

The way you design parts directly impacts the cost

Material

The right material for your project should be considered when examining the overall manufacturing, as you should also take time to take an in-depth look at the properties your part will need. Heat resistance, water resistance, strength, flexibility – the exact properties will depend on the application and use of the final part.

Environment

Environmental factors will greatly affect the design of the part you intend to create. Will the final product be subjected to a great deal of stress or force, as you might expect in an industrial environment? Or will it be used in an office? Basically, you need to consider where and how your parts will be used.

This DFM principle ensures that your part or product can function properly in its intended environment over an optimal lifespan.

Compliance and testing

Your parts may need to adhere to industry-specific, internal and/or third-party standards. If your components will be used in an environment in which food is present, for example, your product must comply with all food-safe standards and regulations. Consider all standards, and plan for testing to ensure that these standards are met, during the DFM process.

Successful DFM analysis minimizes cost while retaining – or even increasing – the performance of a part or product. In addition to the five main principles, these factors will also affect the DFM process:

-

Number of parts: A lower number of parts may require higher relative start-up costs, meaning higher unit prices. The more units you make, the lower the unit price becomes.

-

Product or design complexity: Again, DFM is all about simplifying – meaning the more complex a design, the higher the risk of a costly (or less efficient) production process.

-

Material and component availability: How easy or difficult – in terms of both cost and time – will it be to source the materials and components? The answer will affect the entire DFM process.

-

Design reusability: Will you be able to reuse your design for other projects? Try to think modularly during the design phase, so that future projects may benefit from aspects of the original design.

-

Aesthetics: Does your part’s cosmetic appearance matter? Adding surface finishes, color, custom markings and other aesthetic properties will make production more expensive and time-intensive. It’s best to think about cosmetic qualities during the design process, well before production starts.

What are the benefits of DFM?

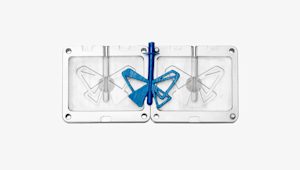

The DFM process reduces costs, lowers lead times and improves the quality of custom parts. This is accomplished by taking steps to minimize the number of parts in your final product, standardize parts for consistency, create modular designs that can be used in future products, facilitate a streamlined manufacturing process and more.

Successful DFM analysis will give you a design that is optimized for production, meaning you will enjoy reduced costs and increased efficiency without sacrificing the efficacy of your parts and products.

How do you get the most out of DFM?

Getting the most out of DFM will depend on the manufacturing process you use: DFM for 3D printing will require different considerations than CNC machining, injection molding or sheet metal fabrication.

DFM for sheet metal, for example, will often require you to factor in locations of bends and fillets, as well as spacing between holes. When using a DFM approach with 3D printing, however – especially when creating a part for prototyping – will benefit from closer examination of mechanical properties such as strength and flexibility.

What’s important here is to be sure that you are familiar with your manufacturing process and its advantages and limitations. DFM can be seen as a preventative measure in avoiding high costs and long lead times. To make the most of it means knowing the ins and outs of your particular use case, application and manufacturing process.

How does Protolabs Network's DFM analysis work?

The Protolabs Network quote building platform uses proprietary Design for Manufacturing (DFM) software to detect potential design issues before production begins, minimizing costs and mitigating potential delays.

This way, you can be certain that you always receive the best price possible at the fastest turnaround times for your custom parts.

Frequently asked questions

What does DFM stand for?

DFM stands for “Design For Manufacturing” or “Design for Manufacturability.” It’s a design-first process that enables designers and engineers to create, iterate, simplify and optimize parts before they are manufactured.

What are the advantages of DFM?

Well-planned and well-executed DFM will result in cost reduction, shorter lead times and improved quality for custom parts

How long does it take to do a DFM check?

DFM checks can take days or even weeks in particular cases, depending on what kind of parts you’re intending to manufacture.

Is DFM analysis expensive?

A DFM analysis requires upfront costs, which vary depending on part and project, but almost always results in saved time and money during actual production.

How does DFM reduce manufacturing costs?

DFM reduces manufacturing costs by simplifying and optimizing a part before it enters production, reducing cost-adding factors like specialized tooling and potential manufacturing failure.