How is nylon made?

Nylon is synthesized through the polymerization of adipic acid and hexamethylene diamine. These raw materials are combined to form nylon salt, which is then heated to create the nylon polymer.

The polymer is then melted and extruded through a spinneret, solidifying into long strands. These strands are drawn to enhance their strength and elasticity. When the material is cooled, its fibers solidify, and the material is ready for use.

Are there different types of nylon?

There are various types of nylon, often referred to as “grades.” These have been developed to suit different applications, and as such offering unique properties and characteristics.

-

Nylon 6. Known for its excellent mechanical properties, toughness, and resistance to chemicals. It is commonly used in applications such as automotive components, textiles, and industrial parts. It is one of the most commonly used nylons in manufacturing.

-

Nylon 6/6 (PA 6/6). Offers high strength, stiffness, and thermal resistance, making it suitable for applications requiring mechanical stability, such as gears, bearings, and structural components. Along with Nylon 6, it is one of the most commonly used nylons in manufacturing.

-

Nylon 4/6 (PA 4/6). A blend of Nylon 4 and Nylon 6, providing enhanced heat resistance and chemical stability. It is often used in high-temperature applications, including automotive under-the-hood components and industrial parts subjected to elevated temperatures.

-

Nylon 6/10 (PA 6/10) and Nylon 6/12 (PA 6/12). Offers improved moisture resistance and lower water absorption compared to other nylon types. They are commonly used in the production of tubing, hoses, and other fluid-handling components.

-

Nylon 11 (PA 11) and Nylon 12 (PA 12). Specialty grades of nylon known for their exceptional resistance to impact, abrasion, and chemicals. They also possess excellent flexibility and low moisture absorption properties. These grades are frequently used in applications such as fuel lines, hydraulic hoses, and pneumatic tubing, particularly in the automotive and industrial sectors.

What manufacturing processes are commonly used with Nylon?

Nylon is used in several manufacturing processes. At Hubs, we focus on the following.

-

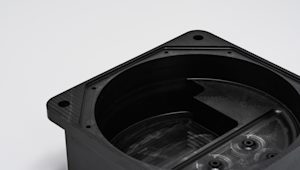

CNC machining. CNC machining with nylon is commonly used to produce high-precision components, gears, bushings, and other mechanical parts for engineering, manufacturing, and industrial applications.

-

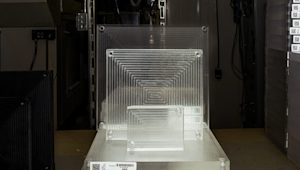

3D printing. Nylon is a popular material for 3D printing, known for its strength, flexibility, and durability. It is used in SLS printing service and FDM 3D printing, enabling the production of prototypes, functional parts, and components used in industries such as automotive, aerospace, and consumer goods. However, it can be difficult to print with and requires high temperatures and special printing conditions.

-

Injection molding. Because it is known for its durability and heat resistance, nylon is commonly used in injection molding. This process allows for the efficient production of sturdy, intricate components.

What are the material properties of nylon?

Nylon’s popularity is in part due to its versatile properties, which often prove beneficial to a wide variety of industrial applications. Let’s take a look at them.

-

Strength and durability. Nylon exhibits high tensile strength compared to most other plastics, making it a robust and durable material for use in applications requiring mechanical strength and resistance to wear, impact, and abrasion.

-

Flexibility and resilience. Nylon is known for its flexibility, allowing it to be formed into various shapes without breaking. It also has a high degree of resilience, enabling it to return to its original shape after being deformed.

-

Chemical resistance. Nylon is resistant to many chemicals, oils, and solvents, making it suitable for use in industrial environments.

-

Heat resistance. Nylon can withstand relatively high temperatures compared to other plastics without significant deformation, making it suitable for applications where thermal stability is essential.

-

Electrical insulation. Nylon exhibits good electrical insulating properties, making it suitable for applications where electrical insulation is required, such as in electronic components and wiring.

How is nylon used? What can you make with nylon?

Nylon is a very versatile material, and as such is used in a great number of industries for a wide variety of applications. Here are a few industries in which nylon is often used.

-

Automotive. Nylon is used for manufacturing components like gears, bearings, engine covers, and fuel lines, thanks to its strength and heat resistance.

-

Consumer goods. Nylon is used in the production of consumer goods including ropes, fishing lines, toothbrush bristles, and zippers, due to its high tensile strength, flexibility, and abrasion resistance.

-

Industrial manufacturing. Components such as rollers, conveyor belts, and machine parts are often manufactured out of nylon, as the material is tough, chemical-resistant, and can withstand high levels of stress and friction.

-

Electronics. Because it is electrically insulating and temperature-resistant, applications in the electronics industry commonly use nylon to produce components such as connectors, insulators, and circuit board fasteners.

-

Aerospace. Nylon is used in the aerospace sector for producing components such as fasteners, bearings, and structural parts that require lightweight materials with high tensile strength and resistance to harsh environmental conditions.

What are the drawbacks of nylon parts?

Understanding the limitations of nylon helps designers, engineers, and manufacturers make informed decisions when selecting materials for specific applications. Here are a few of the drawbacks commonly associated with parts made from nylon.

-

Moisture absorption. Nylon has a tendency to absorb moisture from its surrounding environment, which can lead to dimensional changes and a reduction in some of its mechanical properties if the environment is too moist. However, moisture is also what gives nylon its pliability and toughness.

-

Susceptibility to UV radiation. Nylon can degrade under prolonged exposure to UV radiation with wavelengths of 290–315 nanometers. This can lead to a decrease in its mechanical strength and overall performance. Additionally, nylon will yellow when exposed to constant sunlight.

-

High shrinkage rate. During the cooling process, nylon can experience significant shrinkage, which may cause challenges in maintaining precise dimensional tolerances in molded parts due to warping, especially in larger parts.

-

Brittleness. Nylon can become brittle and stiff when used under its glass transition temperature, leading to part failure or mechanical instability.

What post-processing techniques are commonly used with nylon?

Several post-processing techniques are frequently used with nylon to improve a part’s properties and achieve specific characteristics. Some common post-processing techniques for nylon include the following.

-

Annealing. Annealing is often used to relieve internal stresses in nylon components, which can improve dimensional stability, reduce warping, and enhance overall mechanical properties.

-

Surface treatment. Plasma treatment, chemical treatments, and vapor smoothing can be used to modify the surface properties of nylon, enhancing adhesion for coatings, paints, or adhesives.

-

Machining and finishing. CNC milling, turning, and grinding can be used to achieve precise dimensions and smooth finishes on nylon parts.

-

Dyeing and coloring. Nylon parts can be dyed or colored to achieve desired aesthetic appearances and to provide additional protection against UV radiation or other environmental factors.

What are design considerations for nylon parts?

By addressing these design considerations, you can optimize the performance, manufacturability, and overall quality of your nylon parts.

-

Material selection. Choose the right type of nylon for the specific application. Various grades of nylon offer different properties such as impact resistance, stiffness, heat resistance, and chemical resistance. Understanding the specific requirements of the part can help in selecting the most suitable nylon type.

-

Wall thickness. Maintain uniform wall thickness to prevent issues like warping, sink marks, or voids during the molding process. Additionally, consider wall thickness in consider to the proportions of the part you are designing.

-

Draft angles. If injection molding using nylon, incorporate draft angles into the design to facilitate easy ejection from the mold. Draft angles typically range from 0.5 to 1 degree per side, depending on the texture and geometry of the part. Including appropriate draft angles helps in avoiding surface defects and reducing production costs.

-

Rib design. Integrate ribs into the part design to enhance structural integrity and stiffness without adding excessive weight. Properly designed ribs can improve the overall strength-to-weight ratio of nylon parts.

-

Tolerance and shrinkage. Account for the dimensional changes that occur during the cooling process of nylon parts. Understand the specific shrinkage rates for the chosen nylon grade and adjust the part dimensions accordingly. Incorporate appropriate tolerances to ensure the accurate assembly and functionality of the final product.

Get custom nylon parts

Order CNC machined, 3D printed or injection molded parts using nylon. Just upload a CNC file too receive pricing and lead times. You can also read more about choosing the right materials for your application and our guide to plastics.

Frequently asked questions

How durable is Nylon?

Nylon is highly durable, offering excellent resistance to wear, chemicals, and tough conditions.

Is Nylon brittle?

Nylon can become brittle when used below its glass transition temperature.

How resistant is Nylon?

Nylon exhibits high resistance to chemicals and heat.

What are the common industrial uses of nylon?

Nylon finds widespread use in industrial mechanical parts due to its strength and wear resistance.

Does Nylon have any electrical insulating properties?

Yes, Nylon exhibits good electrical insulating properties, making it suitable for use in electrical components and devices.