Part marking, also known as direct part marking (DPM), is a secondary manufacturing process for adding logos, lettering or other customized designs to your custom CNC-machined parts. Two of the most common methods for part marking are laser engraving and silk screening.

Typically, part marking is a required step in manufacturing full-scale production parts (if you have a lot of parts, you’re probably adding serial numbers or some other identifiers). Of course, you’re likely to find this customization across the full spectrum of CNC projects, especially with the relative ease and cost-effectiveness of most part marking processes.

This article covers common ways to mark parts and also provides practical tips on how to get the most out of part marking techniques. For more in-depth knowledge on CNC machining, head to our comprehensive guide, perfect for new engineers and seasoned ones looking for a handy refresher.

What is laser engraving? Adding logos, serialization and part numbers

Laser engraving is one of the most common methods of part marking. With laser engraving, a laser vaporizes a thin layer of material to create a tracking code, by sending a highly localized laser pulse onto your part.

Instead of adding a raised micro-surface on the material of your part, laser engraving digs into the material. In general, laser engraving can reach a depth of 500 microns. Common applications for laser engraving include steel and aluminum parts.

Benefits

Drawbacks

What is screen printing? Also known as silk screening

Screen printing uses a mesh to transfer ink onto a substrate. The process meets many Mil-Spec requirements for industrial marking methods.

Screen printing machines move a squeegee glade across a screen mesh to fill the open mesh and graphic areas with ink. The screen mesh uses a blocking stencil or emulsion outfitted with an image. After this, a similar print stroke is used, which causes the screen to touch the substrate quickly, pushing ink through the mesh openings and transferring the image onto the substrate.

This method is most commonly seen on parts that have already gone through several metal post-processing rounds. It’s more versatile than traditional printing methods, such as lithography or etching, as it doesn’t require printing under pressure. You can use a variety of different inks to silk screen almost any material or object. Silk screening works well on many plastic and metal materials.

Benefits

Drawbacks

Ready to start producing customized, custom parts?

Our online part marking service Upload a CAD file for a free, instant quote

What is dot peen marking? Also known as pin marking or impression marking

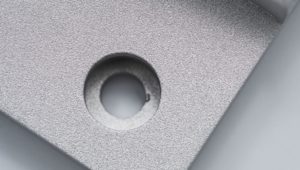

Dot peen marking lets manufacturers make permanent impressions in an impressive range of materials. This is generally for identification and traceability purposes. Dot peening machines use a vibrating tool to produce a series of evenly spaced, small indentations in the surface of a part.

With dot peening, the material of your part is pushed back into a recess and not burned or milled, so you’re not left with excess material shavings.

Benefits

Drawbacks

What is pad printing?

Pad printing uses a silicone pad to transfer a 2D image onto a 3D object. The silicone pad is able to pick up the image from a flat surface and transfer it to a variety of surfaces including flat spherical, cylindrical, textured, concave and convex surfaces.

This process achieves a similar result to silk screening, so we often opt for the latter.

Benefits

Drawbacks

What is laser etching?

Laser etching creates black and white marks on a part and is the most efficient process to permanently add logos and other customized designs to most materials. Etching is faster than engraving because it requires less energy from the laser beam, though the result is pretty similar.

To etch a part, you use a laser to heat and distort the micro surface of the material you’re marking. This expands and creates a texture on the etched surface. Laser etching works with virtually any metal material, apart from SS.

Benefits

Drawbacks

What is laser annealing?

A less common part marking technique, laser annealing is the only solution for marking stainless steel and chrome-plated components. This is because it’s the only process that creates permanent markings while maintaining the part’s natural resistance to corrosion.

Laser annealing heats metal instead of engraving it, chemically modifying the steel located under the initial chromium oxide layer.

To do this, laser annealing heats the surface until it temporarily melts. In this short time span (we’re talking milliseconds), oxygen travels below the surface, creating a controlled form of oxidation beneath this top layer. When the surface cools down and solidifies, oxidation has modified the color of the part’s surface. The result is permanent, chromatic and cosmetic.

Most importantly, laser annealing doesn’t remove any material from the surface of the part, as opposed to laser engraving, which ablates material. This means that any protective layers remain unaffected.

The difference between annealing and etching is that annealing is a chemical reaction and that it does not melt the material’s surface. The difference is subtle to the eye. Common applications include SS and chrome-plated metals.

Benefits

Drawbacks

What is ink stamping?

A relatively simple process for customizing parts, ink stamping consists of pressing an inked stamp onto the surface of a part. It’s the automated version of hand stamping and works well for a variety of plastic and metal materials.

Benefits

Drawbacks

For custom part marking, remember to upload an SVG file with the required text or logos, and a technical drawing that specifies where and how you want your part to be marked. You can also add part marking specifications in a CAD file, though the former method is much preferred.

Did you know we offer local sourcing for CNC machining?

Frequently asked questions

What part marking options are available through Protolabs Network?

We currently offer laser engraving and silk screening for your custom parts.

How much does part marking cost?

In general, laser engraving will add roughly 6% to the final cost of your parts, while silk screening will bring the price up by around 15%.

What’s the difference between laser etching and laser engraving?

The main difference between laser etching and laser engraving is that laser etching melts the micro surface of a part to create raised marks, while laser engraving removes material to create recesses in the surface. Both laser engraving and laser etching use high heat to leave permanent markings on metal surfaces.

What’s the most common technology used for part marking?

The most common technology used for part marking is laser engraving, which we offer at Protolabs Network.

What type of documentation should you provide to Protolabs Network for part marking?

For part marking, you should provide a vector file (AI, Autocad (DWG) and DXF files) as well as a PDF that indicates the exact positioning of the marking.

Does part marking affect lead times?

Part marking will extend the lead time of your custom part orders. Laser engraving will add a minimum of 1 day to your lead times, while silk screening will take an extra 1 to 3 days or more.