Rapid prototyping, commonly carried out through additive manufacturing, allows a designer to develop multiple iterations of a prototype without the additional cost or time that comes with using traditional manufacturing and design techniques.

What are the different types of rapid prototyping?

The fidelity of a prototype—that is, how closely the prototype matches the final product—varies per project, on a spectrum from lower to higher fidelity.

What is lower fidelity prototyping?

We refer to lower fidelity when a prototype loosely matches the final product. The prototype may be used to test overall fit or function without optimizing the design for weight, manufacturability, or finish. The prototype may also be used to test the design only in key areas of concern to the designer or to create a scaled-down version of the final product. An advantage of lower fidelity prototypes is that they typically take much less time to print.

What is higher fidelity prototyping?

We refer to higher fidelity when a prototype closely matches the final product—including geometry, tolerance, and material properties. Higher fidelity prototypes usually take longer to print and have higher associated costs.

What is the right fidelity for your prototype?

The level of fidelity appropriate for a given design iteration depends on overall project goals, the maturity of the design, and the designer’s interests. Determining the appropriate level of fidelity in rapid prototyping can save time in the design process and also optimize resource allocation.

For a single iteration, different prototype attributes such as geometry, material properties, fit-up, and finish may be considered at different levels of fidelity. These considerations impact the prototype’s overall fidelity.

What are the most common rapid prototyping processes?

This high-level summary presents common additive manufacturing techniques typically used in rapid prototyping processes.

Rapid prototyping generally uses additive manufacturing to create test parts, models, or assemblies. However, depending on available resources and a designer’s needs, other more conventional manufacturing processes such as milling, grinding, or casting may be used.

The common prototyping processes can be divided into five groups:

-

Vat photopolymerization

-

Powder bed fusion

-

Material extrusion

-

Jetting

-

Binder jetting

More information for each process is detailed below. For an overview of these rapid prototyping processes, learn more about additive manufacturing technologies.

Vat photopolymerization

A part is created one layer at a time by using light to convert a photopolymer resin to a solid.

Stereolithography (SLA printing) can produce parts with very high dimensional accuracy and intricate details. However, they are generally brittle and their mechanical properties may degrade over time, making the parts typically unsuitable for functional prototypes. This process is best suited for rapid prototyping of design geometry and proof of concept of part interfaces. It is also suitable for details during the early stages of design and when mechanical properties are not the primary design focus.

Direct light processing (DLP) is similar to SLA, with the main difference being level of detail and material properties. Parts produced using DLP do not have the same intricate details as SLA, but do have similar dimensional accuracy and part strength considered equal to or greater than traditional injection molded parts. DLP is therefore best suited for rapid prototyping of design geometry and proof of concept when the design focus is overall geometry rather than specific details, or when mechanical properties are a priority.

Continuous DLP (CDLP), as with DLP, produces parts that do not have the same level of detail as SLA, but do have similar dimensional accuracy and part strength considered equal to or greater than traditional injection-molded parts. CDLP is therefore best suited for rapid prototyping of design geometry and proof of concept when the design focus is overall geometry rather than specific details or when mechanical properties are a design priority.

Powder bed fusion

Powder bed fusion (PBF) technologies produce a solid part using a thermal source that induces fusion, via sintering or melting, between the particles of a plastic or metal powder, one layer at a time. The main variations in PBF processes are determined by the differing energy sources (e.g. lasers or electron beams) and powders (plastics or metals).

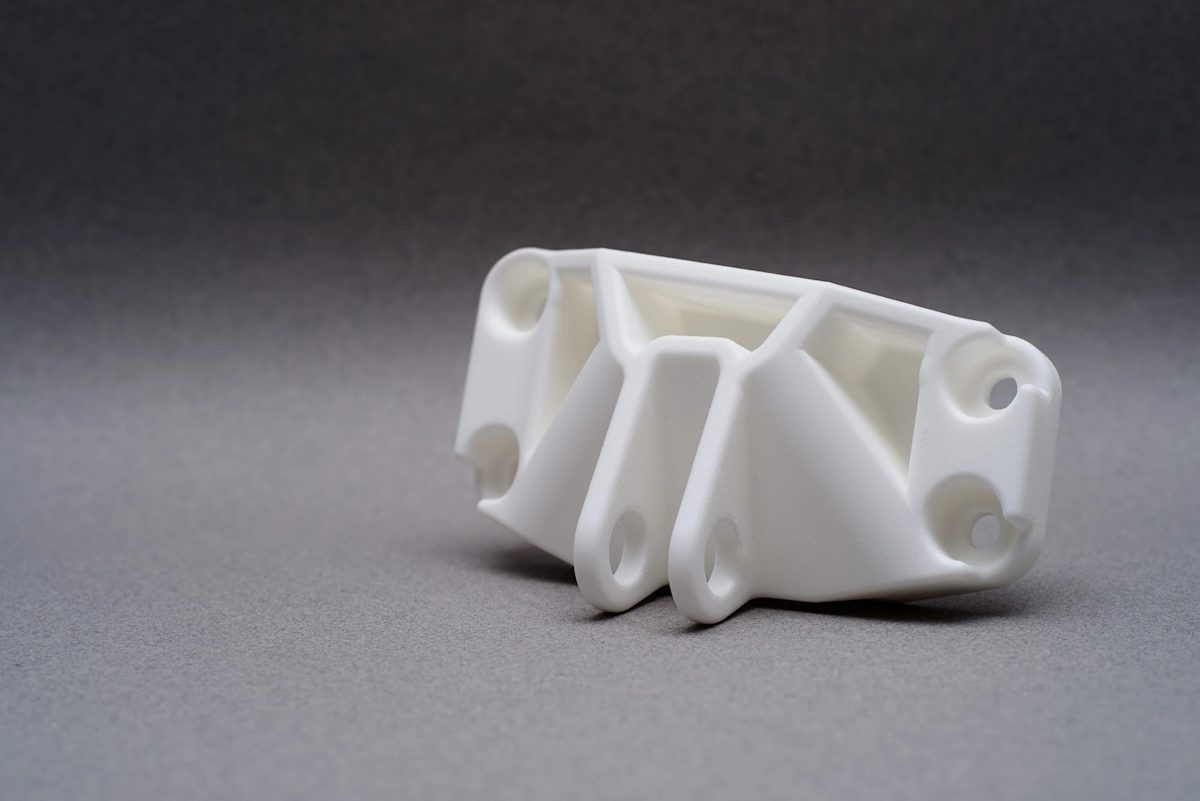

Selective laser sintering (SLS) uses thermoplastic polymer materials that come in granular form. Since SLS parts are printed using many layers, small variations can occur between parts. SLS may therefore be less effective for prototypes with intricate details or small tolerances. A smooth surface finish is also possible to achieve when post-processing is used. SLS is best suited for rapid prototyping when part geometry or overall fit and function are design priorities. SLS may also be advantageous for marketing or proof-of-concept prototypes if post-processing is feasible.

Selective laser melting (SLM) and direct metal laser sintering (DMLS) can be used for a wide variety of metal materials and typically require post-processing for surface finish. These processes are therefore best suited for rapid prototyping when material properties are a design priority. They can be cost-effective if part finish is not a concern.

Electron beam melting (EBM), like SLM and DMLS, is best suited for rapid prototyping when material properties are a design priority and can be cost-effective if part finish is not a concern. The main difference is that EBM has limited material applications (titanium or chromium-cobalt alloys), though may be the most appropriate option for specialty industries that require these materials, such as in the aviation and medical sectors.

Multi-jet fusion (MJF) is very similar to SLS, but with shorter cooling and post-processing times and greater accuracy and detailing. An in-depth comparison of SLS and MJF processes can be found here. As with SLS, MJF is best suited for rapid prototyping when part geometry or overall fit and function are a design priority and can also be used to support higher level of details or tighter tolerances than SLS.

Fused deposition modeling (FDM) is a very versatile process for a wide range of thermoplastic materials with a short production lead time. One downside is that FDM’s dimensional accuracy and resolution are lower than those of other additive manufacturing processes. FDM is best suited for earlier in the prototyping phase, when part geometry or overall fit and function are a design priority. It is also best suited when the final part’s material is similar to the prototype, but there is no concern about details such as functional or reliability testing.

Material jetting is considered one of the most accurate 3D printing technologies and can be used with a wide array of materials in varying colors and finishes. However, material properties are not suited for functional prototypes. Material jetting is best used for rapid prototyping when part geometry or fit is a design priority and part strength is not required. It is also best suited when there is no concern about material properties, such as proof of concept or marketing prototypes.

Nanoparticle jetting (NJP) deposits a liquid that contains metal nanoparticles or support nanoparticles onto the build tray in extremely thin layers of droplets. The build envelope is exposed to high temperatures, which cause the liquid to evaporate and leave behind the metal part structure.

Drop-on-demand (DOD) material jetting printers have two print jets: one to deposit the build materials (typically a wax-like liquid) and another for dissolvable support material. DOD printers deposit material in a pointwise path and employ a fly cutter that trims the build area after each layer to prepare the surface for the next layer.

Binder jetting

Parts made with binder jetting have a high finish and form, though they are brittle. Binder jetting is best suited for rapid prototyping when overall fit or part geometry are a design priority and there is no concern about material properties, such as proof of concept or marketing prototypes.

What are the advantages and disadvantages of rapid prototyping?

Compared to traditional manufacturing and design techniques, rapid prototyping uses modern manufacturing techniques that improve the design process, including improvements in overall cost and time. But when considering rapid prototyping, avoid the pitfalls of overuse, misuse, and misrepresentation.

Here’s an overview of the advantages and disadvantages.

Advantages of rapid prototyping

-

Earlier 3D visualization and testing

-

More design iterations at a lower cost

-

Cost-effective tool for product design and research and development

Disadvantages of rapid prototyping

-

Overuse may not have a positive impact on saving costs or time

-

Not beneficial to all stages of the prototyping process

What are the commercial applications of rapid prototyping?

Applications of rapid prototyping for 3D design and manufacturing are limited only by a designer’s creativity. They can be used throughout all stages of the design and manufacturing process. The most popular use cases are given below.

Proof of concept

One common application is proof of concept. 3D prototypes can be produced quickly and earlier in the design process to evaluate product viability, facilitate design team discussions, generate interest from key stakeholders (e.g. marketing and investment parties), and compare different design alternatives. The primary advantage that rapid prototyping processes provide for proof of concept applications is improvements in cost and time for 3D prototypes.

Design optimization

Rapid prototyping is also a cost-effective way to accelerate optimization, including product design and research and development. A design team can evaluate overall product functionality or focus on key attributes (e.g. geometry, fit, material properties, manufacturability) earlier in the design process without incurring costs associated with traditional manufacturing processes.

High-fidelity prototypes

Due to the versatility of additive manufacturing processes and materials, rapid prototyping can be used to create high-fidelity prototypes that closely match the final product. This often enables designers to demonstrate product functionality or perform reliability testing at lower cost or more quickly than traditional manufacturing processes.

Want to prototype like a pro? Watch this video about FDM 3D printing.