Once you’ve decided to use 3D printing to manufacture your part, you’re faced with the choice of the specific type of 3D printing to use. Your decision should be informed by your part’s requirements, such as mechanical and aesthetic properties, design complexity, and any post-processing your part may need.

What are the types of resin 3D printing?

There are three main types of resin 3D printing. The various processes create parts with slightly different properties.

-

Stereolithography (SLA). The most popular form of resin 3D printing, SLA uses a laser to cure and solidify liquid resin, layer by layer. It’s a great choice for parts – even very large ones – that need high degrees of detail and accuracy.

-

Digital Light Processing (DLP). Uses a digital projector to cure entire layer of resin at the same time, from a single source of UV light (as opposed to SLA, which cures point by point). This means DLP is often faster than SLA, especially when printing larger parts.

-

Liquid Crystal Display (LCD). Also known as masked stereolithography (mSLA), LCD 3D printing uses an LCD screen to project specific light patterns and selectively cure resin layer by layer. This method combines aspects of both SLA and DLP – and aims to be a solution the challenges presented by using a single source of UV light, as with DLP. It’s faster than SLA, and can create parts with high degrees of accuracy and complexity with an entire layer being exposed to UV light at once. LCD 3D printing is usually best for creating larger prints.

What are the benefits of resin 3D printing?

Using resin in 3D printing enables you to create parts that are very accurate, with high degrees of detail and smooth surface finish.

-

High accuracy and detail. Resin 3D printing offers exceptionally high resolution and detail, making it ideal for intricate designs and small parts. In SLA’s case, this means resolutions as high as 25 microns. This means it can create parts with very fine features.

-

Smooth surface finish. Because of its high resolution, resin-printed parts have smoother surfaces compared to parts created with FDM 3D printing.

-

Material versatility. Printable resins are available and relatively easy to access, with specific properties like flexibility, toughness, biocompatibility, and high temperature resistance. There are also special resins for dental, medical, and engineering applications.

-

Rapid prototyping. Resin 3D printing is usually faster than FDM 3D printing, making it well suited to rapid prototyping during the design phase of manufacturing.

-

Complex geometries. In addition to intricate details, resin 3D printing can create parts with complex geometries, making it a good choice for functional prototypes, or sacrificial patterns for casting.

What are the limitations of resin 3D printing?

Here are a few potential drawbacks to consider when making a decision about using resin 3D printing to create your part.

-

Durability. Resin-printed parts are typically weak and brittle when compared to parts created with FDM 3D printing. This means the technology is not usually recommended to print end-use parts.

-

Post-processing. Parts printed in resin often require additional steps after printing, such as washing in isopropyl alcohol to remove excess resin and curing under UV light, so the material fully hardens.

-

Material cost. Resin materials can be more expensive than the filament used in FDM 3D printing.

-

Maintenance and safety. Resin 3D printing often requires more maintenance than 3D printers, as they are more complex machines. Additionally, properly handling and using resin is trickier than filament, as it is potentially toxic or hazardous (although some filaments also present health concerns). You may need to use protective gear and equipment, such as hoods and enclosures.

When should you use resin 3D printing?

Now that we’ve covered the benefits and limitations of resin 3D printing, we can look at the situations in which the technology would work best.

-

Aesthetic or visual prototypes. Resin 3D printing, like many forms of 3D printing, is a good choice for creating prototypes of parts. However, resin-printed parts work best when they do not serve a functional purpose. Instead, the high resolution and smooth surfaces that resin 3D printing can achieve mean that parts created with it often closely resemble an end product. This means resin-printed parts are often used to create visual prototypes.

-

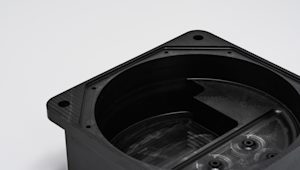

Sacrificial casting patterns. Resin 3D printers are often used to create sacrificial patterns for investment casting. A sacrificial pattern is a temporary that is destroyed or melted away during casting, leaving behind a cavity or mold into which molten metal or other materials are poured to create the final part.

-

Molds and tooling . From master patterns for silicone molds to short-run injection molding tools and inserts, parts created with resin 3D printers are well-suited to creating parts used in injection molding.

-

Medical and dental applications. Resin-printed parts are biocompatible, and as such are used to create custom surgical guides, orthodontic aligners, and custom-fit shells for hearing aids, and other medical parts or tools that must be very accurately designed.

-

Electronics and PCB prototypes. Molds created with resin 3D printers can be used to protect sensitive electronic components in machines or computers. Additionally, resin-printed fixtures and holders are often used to align and test printed circuit boards (PCBs) during the prototyping phase.

Want to learn more about 3D printing with resin? Read our complete guide to 3D printing, or explore the many articles in our Knowledge Base about 3D printing.

Get custom resin 3D printed parts

To receive instant pricing and lead times for your 3D printing project, simply upload your design to our online Quote Builder. We’ll match your request with a manufacturer in our network that is experienced in working with resin. You can also receive personalized advice by contacting networksales@protolabs.com.

Frequently asked questions

How should I design parts for resin printing?

You can optimize designs for resin 3D printing by minimizing overhangs, adding adequate supports, and ensuring there are drainage holes for uncured resin.

What software is best for designing resin-printed parts?

Software like Autodesk Fusion 360, Blender, or ZBrush are great choices for designing parts specifically tailored to resin 3D printing.

What design considerations are important for complex geometries?

Design with support structures in mind to prevent print failures, ensuring that intricate features will be properly supported during printing.

What surface finishes are achievable with resin printing?

Resin printing can produce smooth surface finishes, but you can request post-processing techniques like sanding or polishing to further optimize your part. Refer to our guide to post-processing SLA 3D printed parts.

What are common design mistakes to avoid for resin-printed parts?

Avoid sharp corners, thin walls, and unsupported overhangs.