CNC machining and 3D printing are two of the most widely used digital manufacturing technologies, but they operate in fundamentally different ways.

CNC machining is a widely used subtractive manufacturing process that utilizes rotating cutting tools to precisely shape a solid block of raw material—known as a blank—into finished or near-finished parts. Ideal for both one-off prototypes and medium to high-volume production runs, CNC machining delivers exceptional accuracy, repeatability, and surface quality. It also supports a broad selection of materials, post-processing methods, and surface finish options, making it a versatile solution for custom part manufacturing.

Did you know we offer local sourcing for CNC machining?

In contrast, 3D printing (3DP)—also known as additive manufacturing (AM)—builds parts layer by layer from digital designs. It requires no custom tooling or fixtures, making it a cost-effective choice for rapid prototyping and low-volume production, especially when design flexibility or complex geometries are required.

Despite their differences, CNC machining and 3D printing often overlap in use cases, particularly for prototypes and functional end-use parts made from plastics and metals. In this article, we’ll break down the key considerations—cost, materials, precision, scalability, and more—to help you determine which technology best suits your custom part needs.

3DP vs CNC: How do you choose the right manufacturing technology?

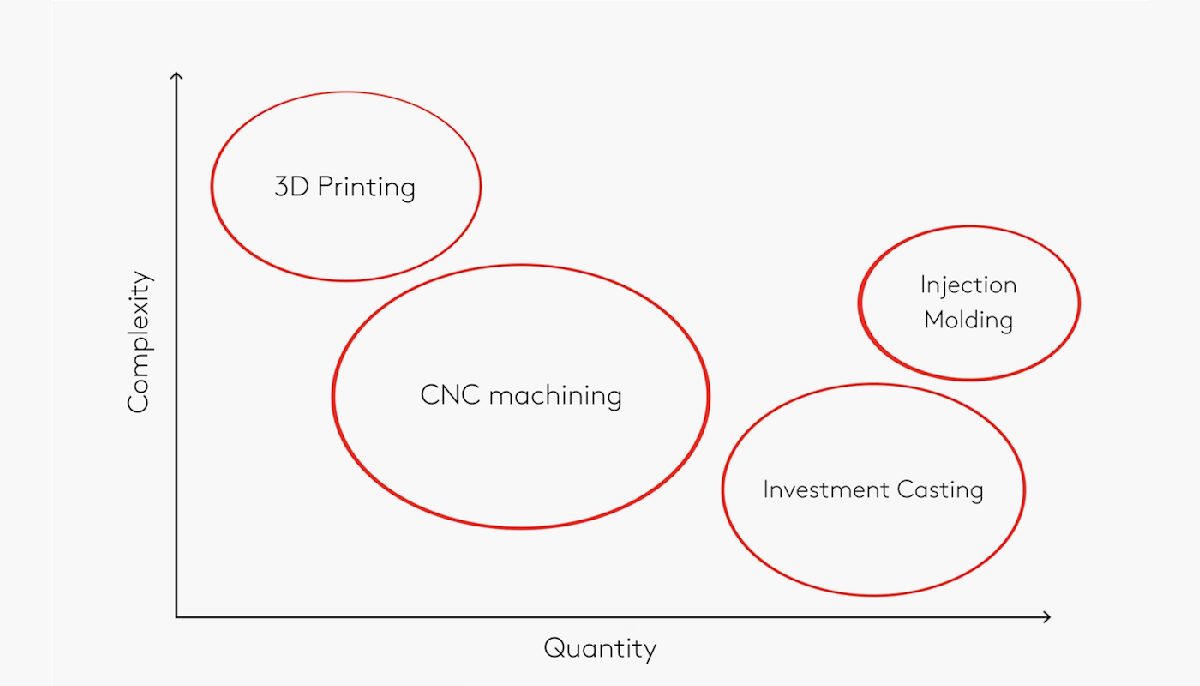

Selecting the right manufacturing process depends on several factors, including part complexity, volume, budget, lead time, and material requirements. We've outlined some practical guidelines below to help you decide between CNC machining and 3D printing—or even a combination of both.

As a general rule, CNC machining is often the better choice if a part can be easily produced using subtractive methods. CNC machining delivers superior dimensional accuracy and consistent mechanical properties across all three axes. However, this precision comes at a higher cost, especially for low-volume production or custom, one-off parts.

When to Choose 3D Printing:

3D printing is the ideal solution in the following scenarios:

-

Complex geometries: Parts with intricate designs, lattice structures, or topology-optimized features that are difficult or impossible to machine.

-

Rapid turnaround: Need parts fast? 3D printing can deliver prototypes within 24 hours.

-

Lower cost for small volumes: Additive manufacturing is typically more affordable than CNC for quantities under 10 units.

-

Specialty materials: Some materials, like flexible TPU or high-performance metal superalloys, are better suited to 3D printing than machining.

-

Budget constraints: When cost-efficiency is key, 3D printing offers a lower barrier to entry due to minimal setup costs and no tooling requirements.

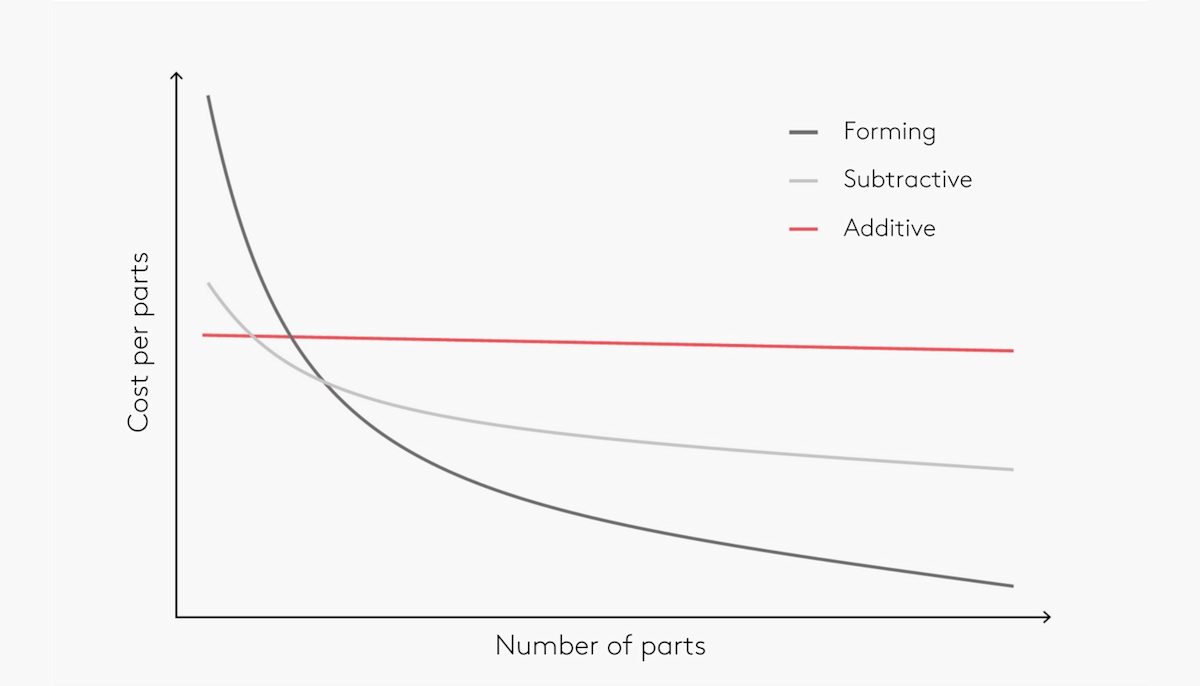

For high-volume production—hundreds to thousands of parts—neither CNC machining nor 3D printing may be the most cost-effective option. Often, injection molding or other traditional forming technologies offer the best economies of scale.

How many parts are you manufacturing? Choosing 3D printing or CNC machining

Production volume is one of the most important factors when deciding whether to use 3D printing or CNC machining for your custom parts. The optimal manufacturing method can vary significantly based on the number of parts you need, the materials you're using, and the complexity of the part geometry.

| Number of parts | 1-10 | 10-100 | 100-1000 | 1000+ |

|---|---|---|---|---|

| Plastic | 3D printing | 3D printing (consider CNC) | CNC machining (consider injection molding) | Inection molding |

| Metal | 3D printing & CNC machining* | CNC machining (consider 3D printing) | CNC machining (consider investment casting) | Investment or die casting |

| *this is highly dependent on part geometry |

Does 3D printing or CNC machining offer better dimensional accuracy?

If dimensional accuracy is a top priority, CNC machining generally outperforms 3D printing. CNC offers high precision, excellent repeatability, and tight tolerances across a wide range of part sizes—from micro-scale components to large structural parts. While CNC-machined internal corners typically have a radius due to tool geometry, external features can be sharp and machined to very thin profiles with high accuracy.

3D printing accuracy, on the other hand, varies depending on the technology and machine used. Industrial-grade additive manufacturing systems (such as SLA, SLS, or DMLS) can achieve excellent tolerances, but they generally don’t match the precision of CNC machining. For parts with tight tolerances or critical dimensions, a common approach is to oversize the printed areas and post-process them using CNC machining.

Other accuracy considerations for 3D printing include:

-

Minimum wall thickness is limited by the toolhead or laser spot size (e.g., nozzle diameter in FDM, laser in SLS).

-

Surface finish often includes visible layer lines, especially on curved surfaces or angled walls.

-

Build volume constraints limit the maximum part size, as many 3D printers require controlled environments to maintain dimensional stability.

In short, CNC machining is the better choice when tight tolerances and smooth surface finishes are essential. However, 3D printing can still be a strong contender for less dimensionally critical features or hybrid workflows.

| Technology | Tolerance | Minimum wall thickness | Maximum part size |

|---|---|---|---|

| CNC machining | ± 0.025 - 0.125 mm* | 0.75 mm | Milling: 2000 x 800 x 1000 mm Lathe: Ø 500 mm |

| SLS | ± 0.300 mm | 0.7 - 1.0 mm | 300 x 300 x 300 mm |

| FDM | Desktop: ± 0.500 mm Industrial: ± 0.200 mm | 0.8 - 1.0 mm | Desktop: 200 x 200 x 200 mm Industrial: 900 x 600 x 900 mm |

| SLM/DMLS | ± 0.100 mm | 0.40 mm | 230 x 150 x 150 mm |

| Binder jetting | ± 0.200 mm | 2.0 mm | 380 x 355 x 735 mm |

| *According to the specified level of tolerance |

Comparing materials: machining metals vs. printing plastics

3D printing and CNC machining are compatible with various materials, including metals and plastics. However, each technology handles materials differently, influencing performance, part quality, and cost.

CNC Machining Materials

CNC machining is especially well-suited for metal parts due to its high precision and excellent mechanical properties. It can also process a broad range of non-metals, including engineering plastics, woods, acrylics, modeling foams, and machining wax.

Material Considerations for CNC Machining:

-

Excellent mechanical and thermal performance, with fully isotropic properties

-

Dimensional constraints based on blank size (non-standard blanks can increase cost)

Common CNC Materials:

-

Plastics: ABS, Nylon, Polycarbonate, PEEK

-

Metals: Aluminum, stainless steel, titanium, brass

3D Printing Materials

3D printing supports a vast and growing selection of materials, from standard thermoplastics and thermosets to advanced metal alloys, ceramics, and even biomaterials. It excels in processing materials that are hard or expensive to machine, like TPU or metal superalloys.

Material Considerations for 3D Printing:

-

Diverse material options with varied physical and mechanical properties

-

Capable of printing materials that are difficult to machine

-

Parts often exhibit anisotropic properties, meaning they may be weaker along layer lines

Common 3D Printing Materials:

What's the best way to manufacture complex parts?

Part complexity is a crucial consideration when selecting between CNC machining and 3D printing. While both technologies have design limitations, CNC machining is generally more restricted in the types of geometries it can produce.

CNC Machining Design Limitations

CNC machining is constrained by factors such as:

-

Tool access and clearance limitations

-

Mounting requirements—parts often need to be repositioned multiple times

-

Rounded internal corners due to the circular shape of cutting tools

-

Inaccessible geometries, even with advanced 5-axis CNC machines

-

Custom fixtures and jigs are needed for complex orientations, which increase time and cost

Because of these constraints, certain intricate shapes and internal features may be impossible or cost-prohibitive to machine accurately.

3D Printing Design Freedom

3D printing, by contrast, offers exceptional geometric flexibility:

-

Easily produces complex, freeform, and organic shapes

-

No need for tool access or multi-sided machining

-

Some technologies (like SLS and MJF) don’t require support structures, enabling the creation of hollow structures, lattices, and internal channels

-

Support structures in processes like FDM or SLA can be removed during post-processing

One of additive manufacturing's greatest advantages is the ability to create highly complex geometries without increasing production cost or time. For applications requiring intricate designs, internal cavities, or lattice structures, 3D printing is often the superior choice.

Comparing manufacturing workflows for 3D printing and CNC machining

Understanding the manufacturing workflow is essential when choosing between CNC machining and 3D printing. Each process involves distinct steps influencing production time, labor requirements, and overall efficiency.

CNC Machining Workflow

CNC manufacturing is often labor-intensive and highly manual, requiring a skilled operator to manage several key variables:

-

Tool selection (end mills, drills, etc.) based on material and geometry

-

Spindle speed and cutting path programming

-

Workholding setup, including secure mounting and possible part repositioning for multi-axis access

-

Machining strategy to ensure tight tolerances and surface finish

-

Post-processing such as deburring, polishing, or surface treatment

These steps require technical expertise and hands-on setup, which can impact production speed, cost, and component quality, especially for complex parts or short runs.

3D Printing Workflow

In contrast, 3D printing is a more automated and digital-first process:

-

The operator begins by preparing the CAD file, selecting part orientation, and adding support structures if needed

-

The file is sent to the printer, which builds the part layer by layer with minimal operator input

-

After printing, parts undergo post-processing steps such as support removal, cleaning, curing, or surface finishing

While the actual build process is largely automated, post-processing can be time-consuming and labor-intensive, depending on the printing technology used (e.g., SLA, SLS, FDM).

Comparing post-processing for 3D printing and CNC machining

Post-processing is critical in enhancing both the functional performance and aesthetic quality of parts produced by CNC machining and 3D printing. Whether you aim for a smoother finish, added durability, or improved surface appearance, various finishing techniques are available depending on your chosen manufacturing method.

Common Post-Processing Methods for CNC Machining

-

Bead Blasting: Creates a uniform matte or satin surface finish by propelling abrasive material at the part. Ideal for removing machining marks.

-

Anodizing (Type II & Type III): Electrochemical process used primarily on aluminum parts. Type II offers corrosion resistance and color options; Type III (hard anodizing) improves wear resistance.

-

Powder Coating: Adds a durable, colored outer layer that improves aesthetics and protects against corrosion, abrasion, and chemical exposure.

Common Post-Processing Methods for 3D Printing

-

Media Blasting: Similar to bead blasting, used to smooth surfaces and remove powder residue (especially for SLS and MJF parts).

-

Sanding & Polishing: Manual or mechanical finishing used to improve surface texture, particularly on FDM and SLA parts.

-

Micro-Polishing: Used for detailed, high-precision parts, especially in SLA or DLP prints, where fine resolution matters.

-

Metal Plating: Adds a metallic layer (e.g., nickel, copper, chrome) for enhanced appearance and strength—commonly applied to plastic 3D prints for improved durability.

3DP vs CNC case study: what if you’re prototyping a plastic enclosure?

When developing a new consumer electronics product, creating functional prototypes—especially for plastic enclosures—is a critical part of the product development cycle. At this stage, speed and affordability are often more important than long-term durability.

Key Prototyping Features for Electronics Enclosures

Electronics housings typically include features like:

-

Snap fits

-

Living hinges

-

Interlocking joints and fasteners

These geometries can be effectively prototyped using both 3D printing (especially FDM and SLS) and CNC machining.

Best Prototyping Technologies for Speed and Cost

-

FDM 3D printing (particularly desktop systems) is the fastest and most cost-effective option for producing enclosure prototypes. It’s ideal for form, fit, and basic function testing—even if surface finish and precision are lower.

-

SLS 3D printing offers better accuracy and surface quality than FDM and doesn’t require support structures, but it comes at a higher cost and with longer lead times.

-

CNC machining provides high precision and a professional finish, making it suitable for cosmetic prototypes or when tight tolerances are needed—but it’s often too costly and time-consuming for early-stage iteration.

Conclusion

When rapidly prototyping electronics enclosures where mechanical performance isn’t the top priority, FDM printing is usually the most efficient option. CNC and SLS are best reserved for final-stage prototypes that require superior detail and appearance.

| Factor | CNC machining | Desktop FDM | SLS |

|---|---|---|---|

| Cost | $$ | $ | $$ |

| Common materials | ABS, Nylon | PLA, ABS, Nylon | Nylon |

| Lead time | 1-2 weeks | 1-3 days | Less than a week |

| Accuracy | ± 0.125 mm | ± 0.500 mm | ± 0.300 mm |

3DP vs CNC cast study: what if you’re manufacturing metal brackets and mechanical components?

Choosing Between CNC Machining and Metal 3D Printing for Mechanical Components

Performance under stress is key when manufacturing metal brackets, fixtures, and mechanical parts. These parts often need to handle high loads, elevated temperatures, and tight tolerances, which means your priority should be dimensional accuracy and reliable material properties.

When to Choose CNC Machining

CNC machining is typically the best choice when:

-

Your design features simple geometries

-

You need high mechanical strength and thermal performance

-

Tight dimensional tolerances are required

-

Cost efficiency is important for small-to-medium production runs

Machining metals like aluminum, stainless steel, or titanium yields strong, high-precision components—ideal for structural parts that don’t require intricate forms.

When to Consider Metal 3D Printing

Metal additive manufacturing (AM)—such as DMLS or SLM—is preferred when:

-

Your parts have complex, organic geometries that are hard or impossible to machine

-

You need lightweight, topology-optimized structures (e.g., aerospace brackets or heat exchangers)

-

You’re using exotic materials like Inconel or cobalt-chrome that are difficult to machine

-

You’re producing low volumes where tooling and fixturing costs are a concern

These technologies enable design freedom and material efficiency, especially for weight-sensitive applications.

Combining Technologies for Best Results

A hybrid approach can offer the best of both worlds:

-

3D print the complex core of the component

-

CNC machine the critical features (e.g., mounting holes, sealing surfaces) to achieve precise tolerances

This method balances design complexity, functional performance, and manufacturing accuracy, making it ideal for mission-critical parts.

| Factor | CNC machining | CSLM/DMLS | Binder Jetting |

|---|---|---|---|

| Cost | $$ | $$$$ | $$$ |

| Common materials | Aluminum, stainless steel, brass | Stainless steel, aluminum, titanium, Inconel, cobalt-chrome | Stainless steel, Inconel, cobalt-chrome, Tungsten carbide |

| Accuracy | ± 0.025 mm | ± 0.100 mm | ± 0.200 mm |

| Mechanical properties | Very good | Very good | Good |

Protolabs Network's top tips & tricks for choosing between 3D printing & CNC machining

We know that selecting the right digital manufacturing technology can be challenging. Whether you're designing a prototype or scaling to production, these expert guidelines will help you make the right call between 3D printing and CNC machining:

Choose CNC Machining When:

-

You're producing medium to high volumes (typically 250–500 parts or more)

-

Your part designs have simple or moderately complex geometries

-

You need tight tolerances and excellent mechanical properties

-

You're working with metal components, and dimensional accuracy is critical

Pro tip: CNC machining remains cost-effective for metals even at lower quantities—just watch out for design features that can’t be easily machined.

Choose 3D Printing When:

-

You're producing low volumes, one-off parts, or prototypes

-

Your part requires highly complex, organic, or topology-optimized geometries

-

You need fast turnaround times and lower upfront costs

-

You're working with materials that are difficult to machine, like TPU or metal superalloys

Note: Technologies like SLS and MJF offer excellent design freedom with minimal post-processing needs.

When to Consider Other Technologies:

-

If you’re printing or machining 500+ identical parts, it may be more cost-effective to shift to injection molding or another form-based manufacturing method

-

In some cases, a hybrid approach—combining CNC or 3D printing with forming or casting—offers the best balance of cost, speed, and scalability

Curious about the costs of 3D printing and CNC machining?

Frequently asked questions

Is CNC machining better than 3D printing?

It depends on your needs. CNC machining is better for parts requiring precision, smooth surfaces, and tight tolerances. 3D printing is ideal for complex geometries and rapid prototyping, with quality varying by printer type. Choose based on material, geometry, and production volume.

What’s the best 3D printing process for plastic parts?

For most prototyping and functional applications, industrial FDM and SLS are the best choices for printing plastic parts. These processes offer good strength, accuracy, and material variety.

What’s the best 3D printing process for metal parts?

SLM/DMLS and Binder Jetting are the top choices for producing functional metal parts and prototypes, offering high strength and precision.

Is 3D printing better than CNC machining for producing prototypes?

For cost and lead times, 3D printing is generally better than CNC machining in the prototyping phase, offering faster turnaround and lower costs.

Will 3D printing make CNC machining obsolete?

No, 3D printing hasn’t replaced CNC machining or traditional methods yet. While 3D printing is advancing with more material options, CNC machining remains the better choice for many applications.