CNC machining is a widely used subtractive manufacturing technology for producing custom metal and plastic components with precision, reliability, and versatility. Guided by digital CAD models, CNC machines use cutting tools to remove material from solid blocks with high accuracy. Engineers often source CNC machining through outsourced manufacturing partners to meet tight tolerances and quality requirements.

This process supports tight tolerances and strong material performance, making it suitable for prototyping and low-to-medium volume production. While CNC machining offers high repeatability, it has design constraints compared with additive manufacturing because material is removed rather than added.

This guide explains how CNC machining works, its core advantages and challenges, and the differences between its two main methods, milling and turning.

Did you know we offer local sourcing for CNC machining?

How does CNC machining work? Let's talk milling and turning

CNC machining uses computer-controlled tools to remove material from solid stock, producing parts with precise dimensions. The process primarily uses two methods: milling and turning. Each method suits specific part geometries and production objectives.

The sections below outline how parts are manufactured on these two machine setups.

How does CNC milling work?

CNC milling is the most widely used type of CNC machining and is often what people mean when referring to CNC. Milling machines use high-speed rotating cutting tools to shape a stationary workpiece mounted on a machine bed.

Most machines operate along three linear axes (X, Y, and Z). Advanced 5-axis CNC mills add rotational movement, which enables the production of complex geometries and reduces the need for multiple setups.

Here’s how a CAD model becomes a finished part through CNC milling:

-

The digital CAD model is converted into G-code, the machine-readable language that guides tool paths.

-

A precisely sized material block, also called a blank or workpiece, is securely mounted to the bed using a vise or clamps.

-

Proper alignment is critical. Tools such as touch probes ensure accurate positioning before machining begins.

-

High-speed cutting tools remove material in multiple stages. A rough pass prioritizes speed, followed by finishing passes for precision.

-

If features cannot be reached from one side, the workpiece is repositioned or flipped for additional operations.

After machining, milled parts require deburring. Deburring is the manual process of removing small defects from a finished part. These defects, generally found on sharp edges, result from material deformation during machining. For example, when a drill exits the far side of a through hole, it leaves blemishes that need removal. This is a standard part of the process when ordering CNC milled parts from Protolabs Network.

Critical dimensions are then inspected to verify that the correct tolerances are achieved. After this, the part is ready for use or for post-processing.

There is more to explore on coatings and finishes for CNC machined parts, so here are helpful resources:

-

Part marking for CNC machining

-

Types of surface finishes for CNC machining

-

Heat treatment for CNC machined parts

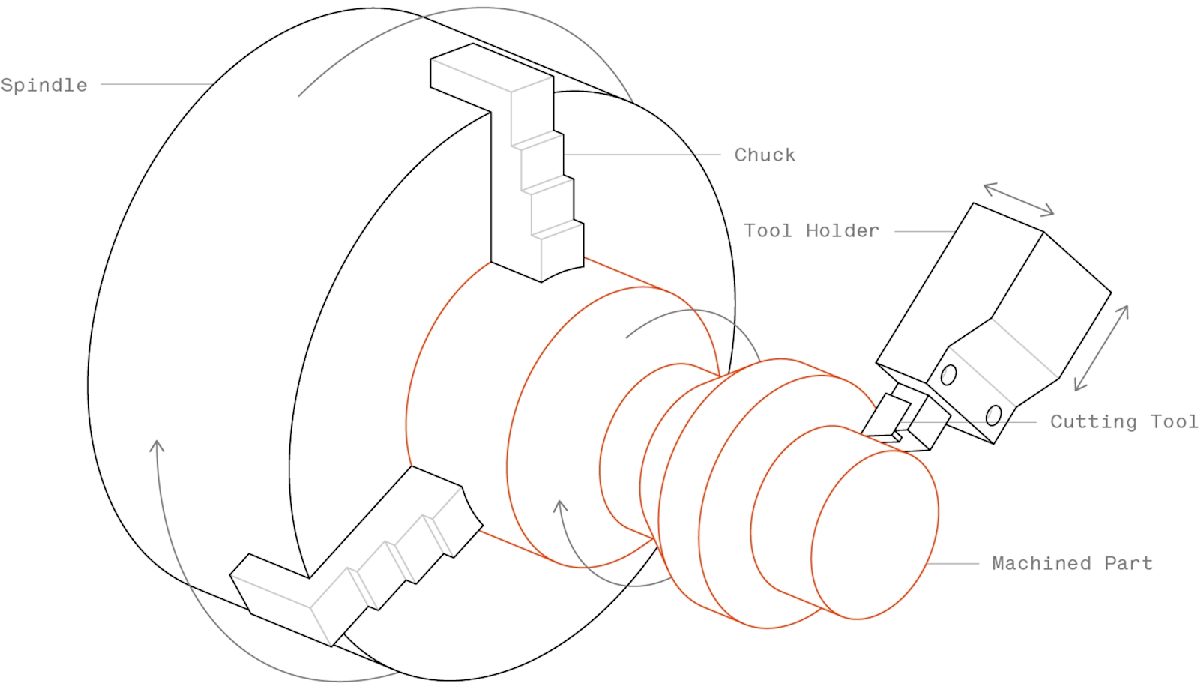

How does CNC turning work?

CNC turning is a subtractive manufacturing process that uses a rotating workpiece and stationary cutting tools to shape parts. It is ideal for components with rotational symmetry. The material is mounted in a spinning chuck, while precise tools cut it to the required geometry.

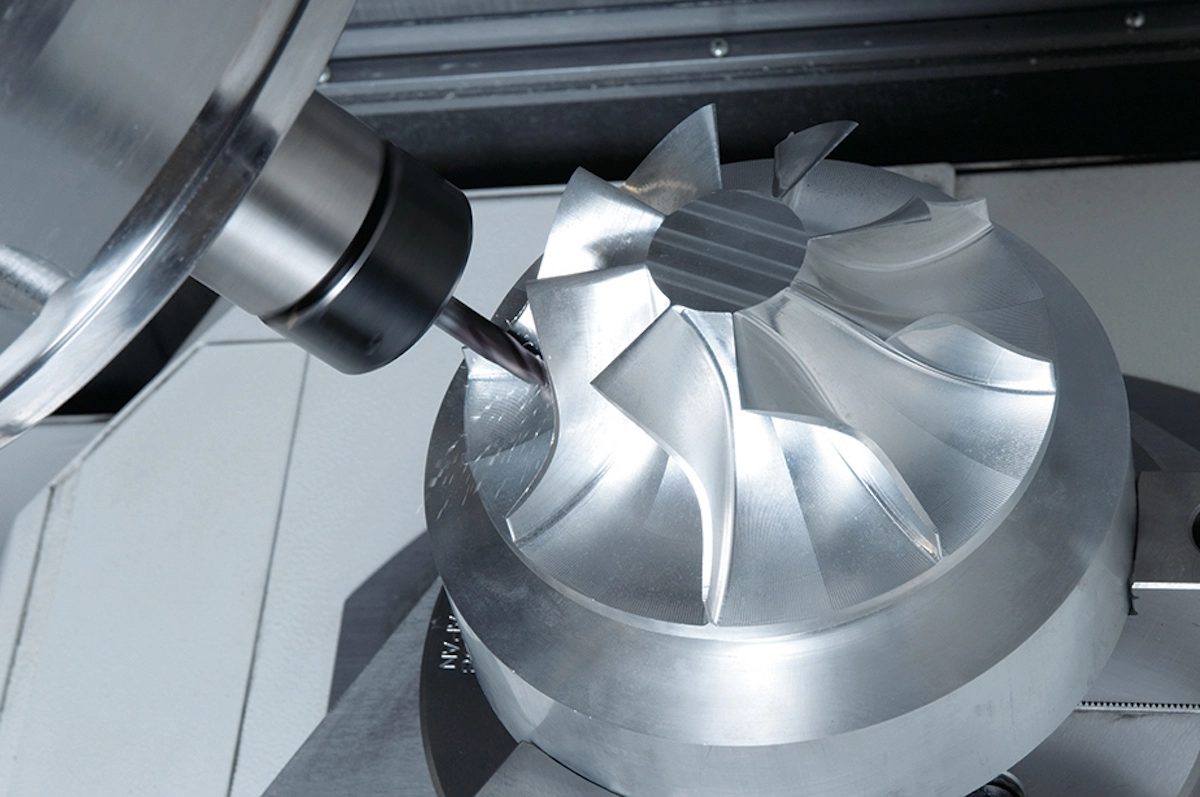

CNC turning, also called CNC lathing, is commonly used to produce cylindrical parts quickly and cost effectively. Advanced multi-axis turning centers can integrate milling to machine complex geometries, enabling parts such as camshafts or impellers in fewer operations. Here is how CNC turning works:

-

The CAD model is translated into G-code that instructs the machine.

-

A cylindrical blank is loaded and spun at high speeds.

-

Stationary cutting tools shape the exterior and can drill along the center axis.

-

For more complex shapes, the part may be flipped or repositioned.

-

Once machining is complete, the part is ready for inspection or post-processing.

A quick guide to CNC machining parameters

CNC machining parameters are typically defined during G-code generation and directly affect part accuracy, quality, and build capacity. Two key considerations are machine build size and dimensional tolerance.

CNC machines offer large build volumes, significantly larger than most 3D printers. For example, CNC mills can handle parts up to 2,000 x 800 x 1,000 mm (78 x 32 x 40 in), while CNC turning can turn parts up to Ø 500 mm (20 in).

CNC machining is known for high precision. Tolerances can be as tight as ±0.025 mm (0.001 in). If no tolerance is specified on the technical drawing, manufacturers typically default to ISO 2768 standards, usually around ±0.125 mm (0.005 in).

What are the most common cutting tools for CNC machining?

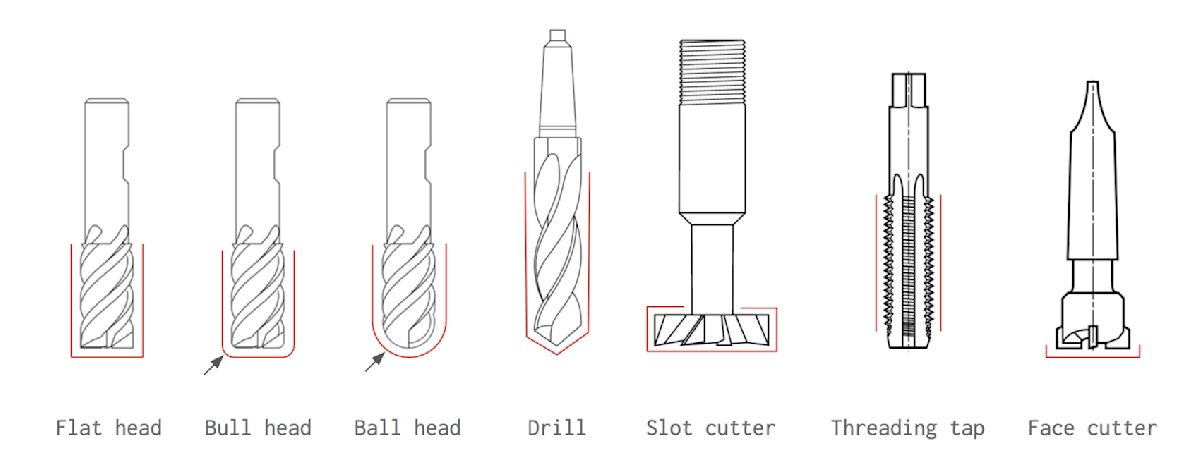

To produce a wide range of part geometries in outsourced CNC milling, shops use a variety of cutting tools tailored to specific operations. In CNC milling, common tools include:

-

Flat end, bull nose, and ball nose end mills: Used to machine grooves, cavities, and vertical walls. Flat and bull nose tools suit sharp or slightly rounded edges, while ball nose tools are essential in 5-axis milling for freeform or contoured surfaces.

-

Drill bits: Used to create holes quickly and efficiently. For non-standard diameters, a plunging flat end mill following a helical toolpath can be used.

-

Slot cutters: Feature a cutting edge wider than the tool shank to remove material from the sides of vertical walls. This is ideal for T-slots and undercuts that standard tools cannot reach.

-

Threading taps: Used to cut internal threads in predrilled holes. Accurate threads require tight synchronization between spindle rotation and tool feed. Many workshops still use manual tapping for high-precision threading.

-

Face milling cutters: Used to machine wide, flat surfaces. Larger diameters than standard end mills allow faster material removal with fewer passes, which reduces cycle time. Face milling is often used early to square the block or prepare a smooth surface for subsequent operations.

CNC turning tools support face cutting, threading, and grooving. These tools are optimized for rotational symmetry and enable high-speed material removal.

CNC machining parts with geometric complexity: what are the design restrictions?

CNC machining provides high precision and strong design freedom, but there are limits compared with additive manufacturing. Greater complexity increases cost and lead time, driven by added setups, tool changes, and part reorientation.

Tool geometry constraints

Most cutting tools are cylindrical with limited cutting depth. Sharp internal corners are difficult to machine, so designs typically include internal radii that match the tool diameter. This constraint can affect feature resolution and detail.

Machine accessibility

In 3-axis machining, tools approach the part vertically, which restricts accessible surfaces unless the part is repositioned. 5-axis machines offer greater flexibility by allowing simultaneous movement along multiple axes, improving access to difficult geometries.

Thin walls and fine features

Thin walls and delicate features are prone to vibration and breakage during machining. Minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics is recommended. Designing beyond these minimums improves manufacturability and durability.

Understanding these limits helps engineers specify CNC friendly parts that meet tight tolerances without unnecessary cost or rework. Additional guidance on optimizing designs for outsourced CNC manufacturing is available in our resources.

What are the characteristics of CNC machining?

One of the key strengths of CNC machining is its compatibility with a wide range of materials, including metals and plastics. For prototypes and end-use parts, CNC machines can process most engineering materials, from aluminum and stainless steel to engineering plastics such as POM, nylon, and ABS.

CNC machining often focuses on metals for both prototyping and production. Aluminum, brass, and titanium are common choices due to their strength, durability, and machinability.

Plastics can also be CNC machined, but they are more challenging because of lower stiffness and melting temperatures. A common use case is machining functional plastic prototypes to validate performance before moving to injection molding for full-scale production, which helps avoid costly design changes later.

Unlike 3D printing, CNC machined parts retain the isotropic mechanical properties of the original bulk material. This makes CNC machining a strong choice for parts that require structural integrity and tight tolerances.

How much do CNC machining materials cost?

Material pricing for CNC machining varies widely by alloy or polymer and by how the material machines. Each material has a different price per blank and also influences total production cost through machinability, cycle time, and tool wear.

For metal parts, aluminum 6061 is often the most cost-effective option because high machinability reduces runtime and tooling costs.

Stainless steel offers excellent strength and corrosion resistance but is significantly harder than aluminum. Higher hardness increases machining time and tool wear, which raises overall cost.

The Protolabs Network platform provides a summary of commonly used CNC machining materials with key characteristics such as strength, machinability, and typical applications. This helps engineers select materials that balance performance and price.

| Material | Characteristics | Cost comparison |

|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low hardness | $ |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine | $$$ |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance | $$ |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents | $$ |

| Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance | $$ |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties, relatively brittle | $$ |

How can I learn more about materials for CNC machining?

Protolabs Network offers a wide range of CNC machining materials with defined properties and advantages. Whether you want to review specific materials or compare options, our resources support material selection for outsourced CNC manufacturing.

For a deeper overview, watch our materials videos on our YouTube channel. These videos explain characteristics, applications, and benefits to help you make informed decisions for your CNC machining projects.

Post-processing and surface finishes for CNC machining

CNC machined parts often show visible tool marks when they come off the machine, which may not meet aesthetic or performance requirements for some engineering applications. To improve appearance, durability, and function, post-processing can be applied to outsourced CNC parts.

Common finishing techniques include anodizing, bead blasting, and powder coating. These finishes enhance surface quality and improve wear resistance, corrosion resistance, and chemical resistance, which is critical for parts used in harsh environments.

This guide offers a general overview. For more detail, see our explainer on common post-processing techniques and surface finishes used in CNC machining to select the right finish for custom parts.

What are the advantages and disadvantages of CNC machining?

While CNC machining is a versatile and reliable process for many applications, from prototyping to medium-scale production of end-use parts, it also has limitations. This section outlines both the advantages and the constraints of this subtractive manufacturing method.

Advantages of CNC Machining

CNC machining offers high accuracy and repeatability. Whether using CNC milling or CNC turning, the process produces parts with tight tolerances, which suits industries such as aerospace, aviation, and automotive. Parts made with CNC machining retain fully isotropic material properties, supporting strength, durability, and precision for demanding engineering applications.

For outsourced production, CNC machining is often efficient for low to medium volumes of metal parts, from single prototypes to batches of up to about 1,000 units.

Disadvantages of CNC Machining

CNC machining has limits due to its subtractive nature. Complex geometries can be costly or impractical to manufacture. Setup costs are typically higher than those of 3D printing. For low-cost plastic prototypes, 3D printing may be faster and more economical because startup costs are lower.

Lead times for CNC machining are also longer than for 3D printing. A typical CNC lead time is about 10 days, while 3D printing often delivers in 2 to 5 days. CNC machines are less widely available than 3D printers and require specialized expertise to operate.

What are Protolabs Network's rules of thumb for CNC machining?

This section outlines the key parameters to consider for CNC machining of custom metal and plastic parts.

| Key CNC parameter | What Protolabs Network says |

|---|---|

| Dimensional accuracy | Typical: ± 0.125 mm (.005’’) Maximum: ± 0.02 mm (.0008’’) |

| Minimum wall thickness | Metals: 0.75 mm (0.030") Plastics: 1.5 mm (0.060") |

| Maximum build size | Milling: 2000 x 800 x 100 mm (78’’ x 32’’ x 40’’) Turning: Ø 500 mm (Ø 20’’) |

Ready to get your CNC parts into production?

Get a Quote

Ready to explore pricing and lead times for your next CNC machining project? Upload a CAD file to get a free, instant quote.

Frequently asked questions

What's the best application of CNC machining?

CNC machining suits one-off parts and low to medium volumes, from hundreds up to about 1,000 units. It is cost effective for metal prototypes and for parts that require tight tolerances.

What are the most common CNC machining cutting tools?

Common tools include drills, slot cutters, threading taps, face milling cutters, and flat end, bull nose, and ball nose end mills.

Which industries use CNC machining the most?

CNC machining is widely used in aerospace, automotive, aviation, transportation, and other industrial sectors. Aircraft components, for example, require high precision to ensure system performance.

Is CNC machining completely automated?

CNC machining is highly automated and relies on preprogrammed software. CAD data defines the part geometry that the machine follows. Limited operator input is needed for setup, fixturing, and inspection, and complex designs may require additional manual steps.

What's the general surface texture of CNC milled and turned parts?

Milled parts typically have a surface roughness around 3.2 µm, or about 1.6 µm on newer machines. Turned parts can reach about 0.8 µm, which supports consistent cutting speeds without adjustments.

How do you speed up CNC manufacturing?

Cycle time depends on part design and required surface finish. Using fillets instead of sharp internal corners allows standard tooling and reduces tool changes, which shortens machining time.