3D printing is used for prototyping and end-use components in aerospace and aviation, especially when engineers outsource production to qualified additive suppliers. Additive parts can achieve high strength-to-weight ratios compared to machined or cast parts when designed for SLS, MJF, or metal LPBF.

Aerospace adopted industrial 3D printing early and continues to advance process and material development. The sector began using 3D printing in 1989, and in 2015 it accounted for about 16 percent of the $4.9 billion global additive market.

This article explains how industrial 3D printing impacts aerospace and aviation, from prototyping to production. We outline engineering requirements for aircraft components and provide design guidance for common and specialized applications, including strain limits, tolerance selection, build direction and fastening. We review qualified materials for flight hardware and ground support equipment, and present a case study from an outsourced production network.

Implementing 3D printing in the aerospace design workflow

Engineers in aerospace and aviation can apply industrial 3D printing at every stage of the design workflow. The major stages below indicate where outsourced additive manufacturing reduces lead time and supports qualification.

Design communication

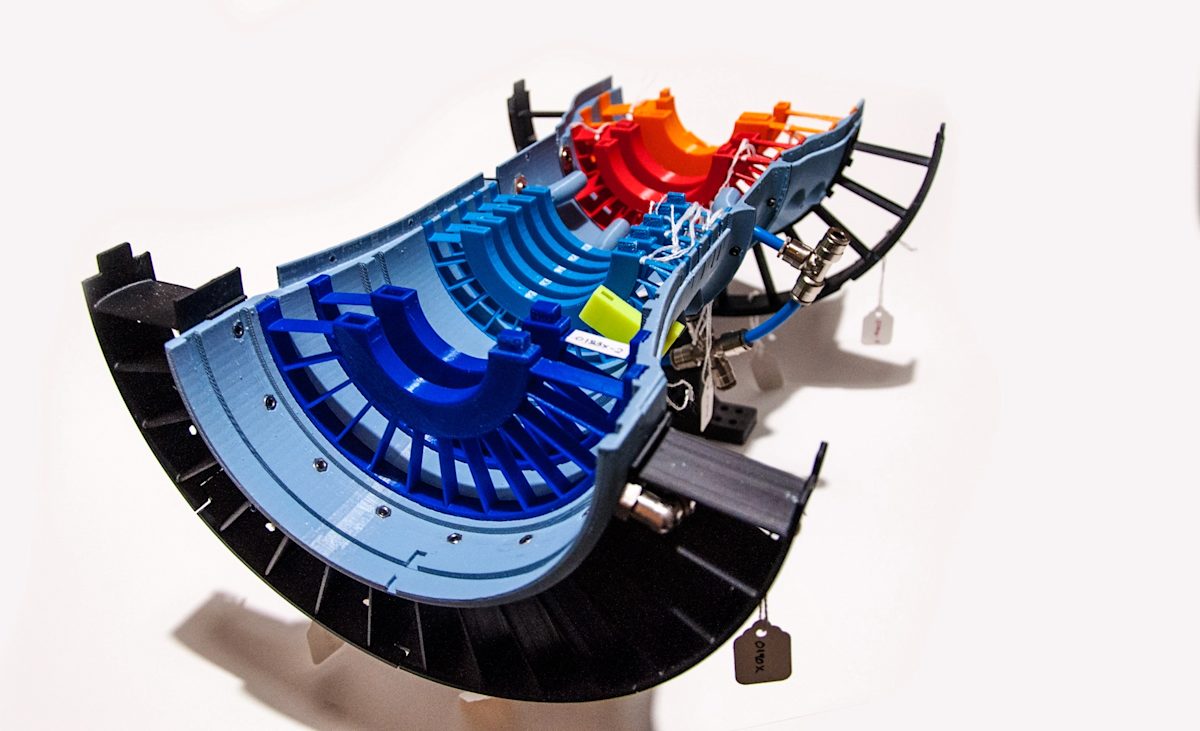

Aerospace designs often start with concept models that represent an aircraft component. These models are also used for aerodynamic testing in wind tunnels, where surface quality and accuracy are critical. SLA and material jetting produce smooth, high‑detail scale models with tight tolerances suited for aero evaluation. Accurate parts communicate design intent and show overall form, and outsourced production with a qualified supplier network supports rapid, repeatable iterations.

Validation

Prototyping with industrial 3D printing is standard across aerospace programs. Applications range from a full-size landing gear enclosure printed quickly with cost-effective FDM to a high-detail, full-color control board concept model. A suitable additive process exists for each prototype. Engineering-grade materials support functional tests and validation, and an outsourced supplier network shortens lead time while maintaining traceability.

Pre-production

Industrial 3D printing is an effective route to rapid tooling for injection molding, thermoforming, and jigs and fixtures. For aerospace programs, outsourced additive tooling enables fast, low cost production of mold inserts, trim tools, drill jigs and assembly fixtures that support low to medium runs. This reduces risk before committing to high cost hard tooling at the production stage and can also deliver production components in volumes up to 5,000 to 10,000 parts, with process traceability.

Production

Production volumes in aerospace can exceed 70,000 parts per year, so historically industrial 3D printing served mainly for rapid prototyping rather than flight hardware or other end-use components.

Today, larger industrial printers, faster build rates, and qualified materials make additive manufacturing viable for medium-sized production orders, particularly for high-end interior assemblies, when executed through an outsourced supplier network that offers repeatable quality, process traceability, and aerospace-compliant documentation.

Customization

Industrial 3D printing delivers value in aerospace when a measurable performance gain justifies the cost of producing highly complex one-off components, especially when production is outsourced to a qualified additive supplier.

Corporate aircraft average about 75,000 miles per month. A single aerodynamically optimized component produced with 3D printing can reduce drag by 2.1 percent and lower fuel costs by 5.41 percent.

Parts are tailored to a specific aircraft, such as custom lightweight brackets, or to an aircraft type including cargo, passenger, or helicopter. Industrial 3D printing via an outsourced supplier network provides part consolidation and topology optimization for custom aerospace components.

How is 3D printing used in aerospace engineering?

Jigs & Fixtures

Industrial 3D printing is used to produce aircraft jigs and fixtures, including guides, templates, and gauges. For each aircraft, hundreds of these tools are outsourced to additive suppliers and 3D printed, delivering 60 to 90 percent reductions in cost and lead time compared to conventional manufacturing.

Surrogates

Surrogates are placeholder parts used during production that represent components later installed in the final assembly. They are primarily used for training and build practice. Aerospace programs, including NASA and Air Force facilities, commonly use 3D printed surrogates produced on demand through qualified outsourced suppliers.

Mounting brackets

Outsourced industrial 3D printing produces structural, low-volume metal brackets with DMLS or SLM that secure critical life-saving systems to interior aircraft structures.

High detail visual prototypes

Material jetting 3D printing produces multicolor prototypes with a surface finish comparable to injection molding and fine feature resolution. These models enable accurate assessment of form and fit before production decisions.

This high accuracy prototyping method is well suited for aerodynamic testing and analysis because the surface finish achieved with industrial 3D printing is often representative of the final part.

Industrial 3D printing is routinely used to manufacture aerospace components where aesthetics take priority, such as door handles, light housings, control wheels, and full interior dashboard assemblies.

How does 3D printing improve aerospace manufacturing?

Geometric design freedom

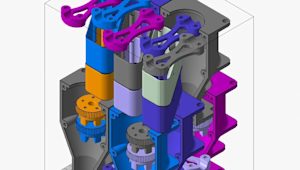

Aerospace applications use advanced engineering materials and complex geometries to reduce weight and improve performance. Additive manufacturing enables internal channels for conformal cooling, integrated internal features, thin walls, and complex curved surfaces.

3D printing can produce these features and supports the fabrication of highly complex, lightweight structures with high stability. This design freedom enables topology optimization and the integration of functional features into a single component.

In addition, processes such as SLS, DMLS/SLM, and binder jetting support small batch production at reasonable unit costs.

Consolidating assemblies into a single part

Design freedom in industrial 3D printing enables consolidation of multiple parts into a single component. This reduces weight and cost and lowers inventory across production and spares.

Surface finish

Controlling surface finish is critical in aerospace, and 3D printed parts can be post processed to a very high surface quality. Material jetting can produce an injection molding like finish directly from the printer with minimal post processing. High performance metal parts produced with DMLS/SLM, and low cost metal parts produced with binder jetting, can be smoothed and polished, or CNC machined, after printing to improve accuracy and surface finish.

Part orientation

For functional load-bearing parts, orientation on the build platform is critical. Due to the layer-by-layer nature of 3D printing, most parts have anisotropic mechanical properties and are weaker in the Z direction. Factor this into the design to meet strength and durability requirements.

Support structures

Support structures provide a stable base for depositing material above overhangs and at steep walls above 45 degrees. In metal 3D printing, support is critical to anchor parts to the build plate and to limit distortion and warping during the build.

Surfaces printed on support structures typically have lower surface quality and may show witness marks after support removal. If that is not acceptable for the application, consider processes that do not require supports, such as SLS or binder jetting.

What are the best materials for 3D printing aerospace and aviation parts?

Engineers select industrial 3D printing materials with high strength-to-weight, thermal stability, and FST compliance for aerospace and aviation components. See the table below for a detailed comparison of materials used to 3D print custom parts.

| Application | Example part | Requirements | Recommended Process | Recommended Material |

|---|---|---|---|---|

| Engine compartment | Tarmac nozzle bezel | Heat resistant functional parts | SLS | Glass-filled Nylon |

| Cabin accessories | Console control part | Customized functional knobs | SLA | Standard Resin |

| Air ducts | Air flow ducting | Flexible ducts and bellow directors | SLS | Nylon 12 |

| Full size panels | Seat backs & entry doors | Large parts with smooth surface finish | SLA | Standard Resin |

| Casted metal parts | Brackets and door handles | Metal parts casted using 3D printed patterns | SLA & Material Jetting | Castable Resin or Wax |

| Metal components | Suspension wishbone & GE Jet Engine | Consolidated, lightweight, functional metal parts | DMLS/SLM | Titanium or Aluminum |

| Bezels | Dashboard interface | End use custom screen bezels | Material Jetting | Digital ABS |

| Lights | Headlight prototypes | Fully transparent, high-detail models | Material Jetting & SLA | Transparent Resin |

3D printing in practice: Printing parts for satellites

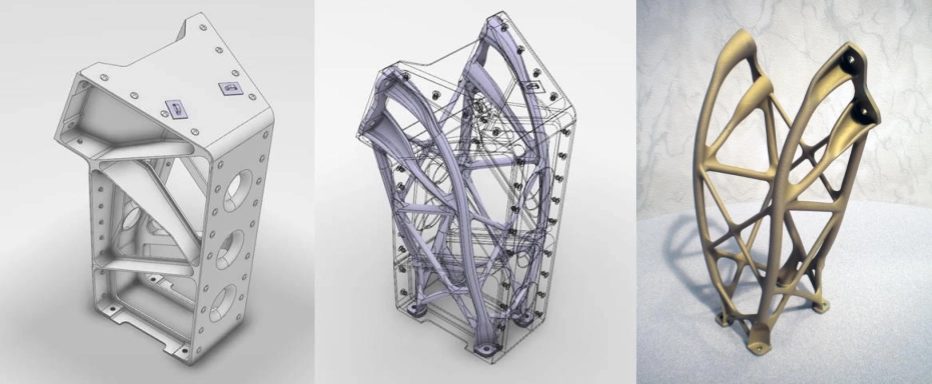

Satellite designs include geometrically specific brackets that link the satellite bus to reflectors and feed assemblies at each end. Producing these critical brackets presents two primary challenges.

These brackets must securely attach reflector and feed components to the satellite bus. They also must withstand thermal cycling across temperatures from -170 to 100 degrees Celsius and the resulting mechanical stress. Few materials can meet these performance requirements.

Airbus engineers addressed these challenges by 3D printing the brackets in titanium, selecting additive manufacturing to meet strength and thermal cycling requirements. Producing the parts additively reduced raw material waste compared to machining, consolidated multiple subcomponents into a single bracket to simplify assembly, and enabled geometry optimization that preserved load paths while removing noncritical mass. The result is a lighter bracket that maintains mechanical performance. Lower part weight and fewer manufacturing steps reduced production cost, and the mass reduction will save fuel over the satellite life cycle.

Ready to make custom parts faster & lighter?

Explore our 3D printing capabilities Get a free, instant quote today