When engineers need cylindrical parts with tight tolerances and smooth finishes, CNC turning machines deliver precision that's hard to beat. These workhorses of the manufacturing world excel at creating everything from simple bolts to complex camshafts, often faster and more cost-effectively than other machining processes.

Understanding CNC machining

Knowing the fundamentals of CNC (Computer Numerical Control) machining helps engineers choose the right process for their parts.

CNC machining service is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from solid blocks, creating precise parts directly from CAD files. The two main types of CNC machining are milling and turning, each optimized for different part geometries.

CNC milling uses rotating cutting tools to shape stationary workpieces, making it perfect for complex prismatic parts with intricate features. The cutting tool spins while moving along multiple axes to carve away material.

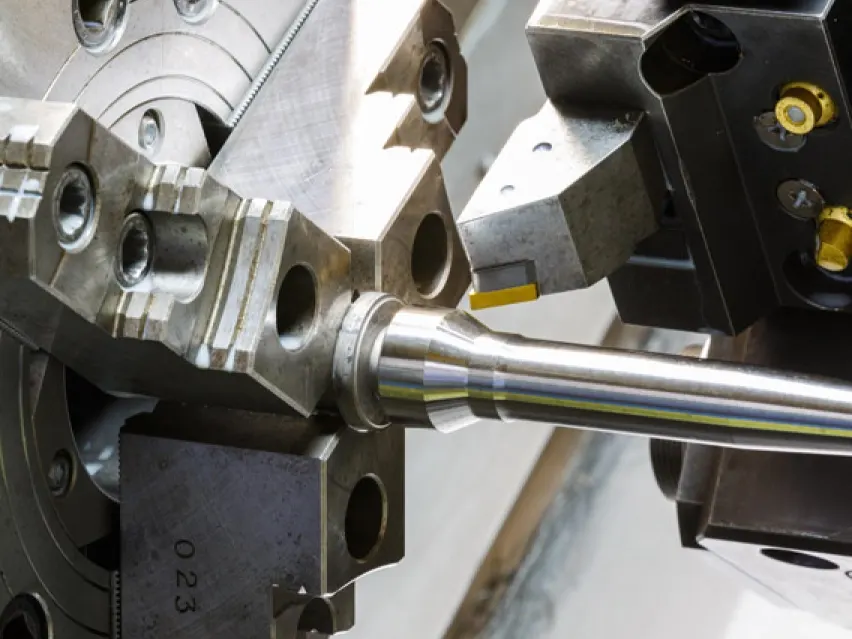

CNC turning flips this approach. The workpiece spins at high speed while stationary cutting tools shape it into the right geometry. Think of it like a high-tech pottery wheel, except instead of clay, you're working with metals and plastics, and instead of hands, you're using computer-controlled cutting tools. This makes turning perfect for cylindrical parts like shafts, pins, and threaded connectors.

Unlike milling, where the cutting tool rotates and the part stays fixed, turning is ideal for parts with rotational symmetry. If you can imagine your part spinning around a central axis without looking different, chances are turning is your best bet.

How CNC turning machines work

The accuracy and repeatability of CNC turning machines comes from the way they coordinate motion, tooling, and cutting parameters. In simple terms, the machine spins a piece of material at high speed while stationary tools shape it. A cylindrical blank (the raw material) is clamped into a chuck—a powerful grip that holds the workpiece steady—while it rotates at thousands of revolutions per minute. As the workpiece spins, cutting tools move along linear axes (X for radial, Z for lengthwise) to carve out the programmed design. Unlike CNC milling, where the tools rotate, here it’s the part itself that turns while the cutting edges do the shaping.

The process usually happens in two stages:

-

Roughing passes: Quickly remove extra material to get the general shape.

-

Finishing passes: Fine-tune the details, hitting tolerances of ±0.025–0.125 mm (±0.001–0.005") and achieving surface finishes around 0.8–3.2 μm Ra.

Different cutting tools step in depending on the job:

-

Face cutting tools: Square off ends and create flat surfaces.

-

Threading tools: Create internal or external threads.

-

Grooving tools: Cut channels and undercuts.

-

Boring tools: Expand internal features and holes.

Engineers guide all of this by programming a digital model into G-code, which the CNC machine executes with precision and consistency.

And while the tools do the cutting, a few key subsystems keep everything running smoothly:

-

Spindle: This is what spins the workpiece. The faster it goes, the more parts you can produce in less time.

-

Turret: Think of it as the tool rack. It can hold several tools at once and swap them in quickly, which keeps cycle times short.

-

Coolant system: Keeps everything cool, helps tools last longer, and leaves a cleaner finish on the part.

CNC turning machines come in different configurations to suit part complexity and production needs:

-

Basic CNC lathes: Best for simple cylindrical parts like shafts, pins, and bushings. Cost-effective with excellent finishes at high volumes.

-

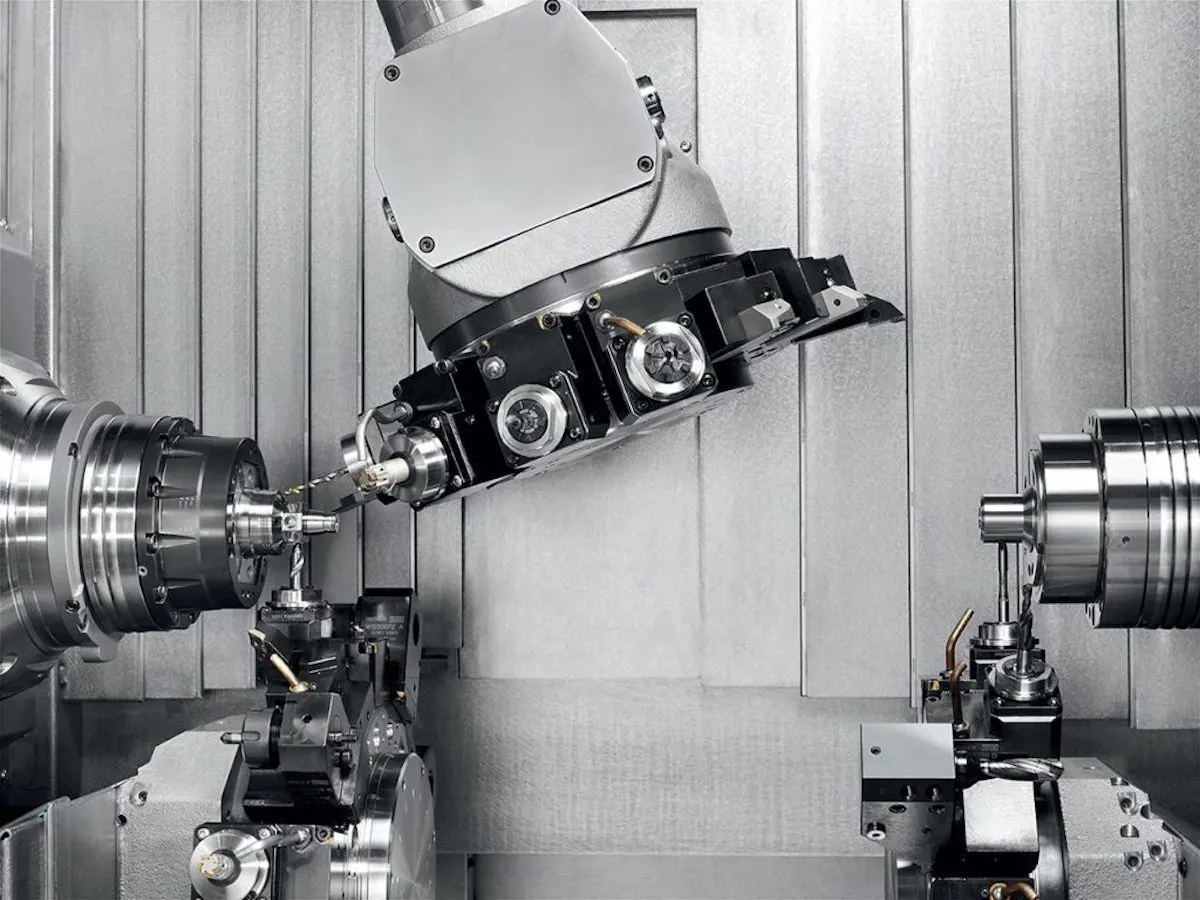

Multi-axis turning centers: Add flexibility with live tooling, cross-drilling, and flat milling. Good when you need multiple features in fewer setups.

-

Mill-turn centers: The most versatile option, offering full 5-axis capabilities. Ideal for complex geometries, reducing handling, and producing intricate parts in a single setup

At the end of the day, all CNC turning machines follow the same principle: rotating material against a cutting tool. The machine you choose depends on whether you need the efficiency of a simple lathe, the added features of a turning center, or the versatility of a mill-turn machine.

CNC turning machines across industries

CNC turning machines show up in just about every industry that needs round parts, which is pretty much all of them. They're reliable, precise, and leave a smooth finish, making them the go-to choice for critical components.

-

Aerospace manufacturing: Turbine shafts, landing gear pins, and hydraulic fittings all have to survive tough conditions. Turning is perfect here because it delivers consistent accuracy on parts that absolutely can't fail.

-

Automotive manufacturing: Crankshafts, brake rotors, and engine parts all need to spin smoothly. Turning makes sure they stay perfectly round and balanced, which keeps cars running safely.

-

Medical manufacturing: From implants to surgical tools, many medical parts are small and cylindrical. Turning gives them the fine detail and smooth finishes needed for patient safety and comfort.

-

Electronics manufacturing: Connectors, sensor housings, and tiny shafts need to be both precise and compact. Turning handles these small, detailed parts with ease.

-

Robotics and automation: Joints, shafts, and actuators have to fit together perfectly for smooth motion. Turning creates the tight fits and clean surfaces that keep robots moving the way they should.

-

Industrial machinery: Pump shafts, rollers, and couplings are built for nonstop work. Turning makes them tough, accurate, and reliable enough to keep machines running day in and day out.

If it's round and needs to spin, there's a good chance a CNC turning machine made it possible.

Advantages and disadvantages of CNC turning

Understanding when CNC turning excels, and when other processes might be better, helps engineers make smart manufacturing decisions. Below we've broken down the main advantages and disadvantages to guide your decision-making.

Advantages

Turning offers several benefits that make it the go-to choice for cylindrical components:

-

Speed and efficiency: For cylindrical parts, turning achieves very high material removal rates thanks to continuous cutting action

-

Superior surface finish: The consistent tool-to-work contact produces excellent surface finishes, often eliminating secondary operations

-

Cost-effectiveness: Especially at medium to high volumes, turning delivers lower per-part costs than milling, with shorter setup and cycle times

-

Material utilization: Using round bar stock minimizes waste compared to milling rectangular blocks

-

Excellent concentricity: Features machined in a single setup maintain perfect concentricity, critical for rotating assemblies

Disadvantages

Despite its strengths, CNC turning isn't always the best fit. Keep these drawbacks in mind:

-

Geometric limitations: Parts without rotational symmetry or those requiring prismatic features are better suited for CNC milling

-

Limited feature accessibility: Internal features not reachable from the ends of a part may be difficult or impossible to machine with turning

-

Fixturing challenges: Very short, thin, or unusually shaped parts can be difficult to secure, affecting accuracy and tolerances

By weighing these pros and cons, engineers can decide whether CNC turning is the right solution or if another process like milling, sheet metal fabrication, or injection molding will deliver better results.

Turning vs. other manufacturing processes

CNC turning is a powerful way to make round parts with speed and precision, but it’s not the only option out there. Depending on the shape, complexity, and volume of your part, milling or another process might be a better fit.

Turning compared to milling

| Factor | CNC Turning Machines | CNC Milling Machines |

|---|---|---|

| Best for | Cylindrical/round parts | Prismatic/complex geometries |

| Material removal rate | High (continuous cutting) | Lower (interrupted cutting) |

| Surface finish | Excellent (0.8–3.2 μm Ra) | Good (1.6–6.3 μm Ra) |

| Tolerances | ±0.025–0.125 mm (±0.001–0.005") | ±0.025–0.125 mm (±0.001–0.005") |

| Maximum part size | Ø431 mm × 990 mm (Ø17" × 39") | 2000 × 800 × 1000 mm (78" × 32" × 40") |

| Setup complexity | Lower | Higher |

| Cost per part | Lower for round parts | Higher overall |

| Maximum complexity | Limited to rotational features | Very high with 5-axis |

When to consider other processes

If CNC machining isn’t the best fit, here are some alternatives:

-

3D printing: Ideal for complex geometries, rapid prototyping, and low-volume production.

-

Sheet metal fabrication: Best for flat, thin-walled, or bent parts where speed and cost-efficiency matter.

-

Injection molding: The most economical choice for high-volume production of plastic parts with consistent quality.

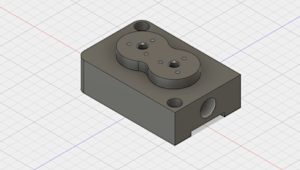

Design considerations for CNC turning machines

A few smart design decisions early on can go a long way in keeping costs down and making sure your parts work as intended. Here are some key things to keep in mind when designing for turning:

-

Tolerances: Standard tolerances are about ±0.05 mm (±0.002"), and you can push that down to ±0.025 mm (±0.001") with finishing passes. But be selective because specifying ultra-tight tolerances everywhere will only drive up cost without adding value.

-

Wall thickness: Aim for at least 0.8 mm in metals and 1.5 mm in plastics. Thicker walls are easier to machine, hold their shape better, and help reduce vibration.

-

Length-to-diameter ratio: Keep it under 10:1 if you can. Anything longer usually needs tailstock support, and going beyond that adds complexity (and cost).

-

Internal corners: Expect a radius that matches the tool nose (typically 0.4–1.6 mm). If you really need sharp corners, that usually means special tooling or a secondary operation.

-

Threads: M6 or larger is the sweet spot. Very small threads, like M2, are possible but drive up machining time and cost because they require specialised tools.

-

Material choice: Turning works with a wide range of metals and plastics. Softer materials like aluminium and Delrin machine quickly and leave great finishes, while tougher options like stainless steel need careful programming to avoid work hardening.

What's new with CNC turning machines

The CNC world keeps turning, and the latest innovations are making these machines smarter, faster, and more versatile than ever. Recent upgrades bring real advantages to engineers and manufacturers alike:

-

IoT and AI integration: Machines can now monitor themselves in real time, predict when maintenance is needed, and even make small adjustments on the fly. That means less downtime and more consistent output.

-

Hybrid mill-turn centers: By combining turning and milling in one setup, these machines make it possible to tackle complex parts without juggling multiple processes.

-

Smart tooling and wear detection: Built-in sensors and AI models track tool wear, so you can swap tools before quality drops or failures happen, extending tool life in the process.

-

Automation upgrades: From faster bar feeders to robotic arms, automation has made it easier than ever to keep machines running around the clock with minimal supervision.

These innovations keep CNC turning machines relevant for both high-volume manufacturing and precision applications, giving engineers access to capabilities that weren't possible just a few years ago.

Why use Protolabs Network for CNC turning

From prototyping to production, our comprehensive turning capabilities and quality standards ensure your cylindrical components meet exact specifications.

-

Advanced CNC turning network: Access to everything from basic 2-axis lathes to sophisticated 5-axis mill-turn centers with live tooling.

-

50+ materials available: From common aluminum alloys to specialized materials like titanium and Inconel, matching your application requirements.

-

Tight tolerances: Precision down to ±0.0008" (±0.02 mm) for critical features.

-

Rigorous quality assurance: Parts are inspected on-site with documentation available. Protolabs Network is AS 9100 D / ISO 9001: 2015 certified and additional certifications are available through our manufacturing partners.

-

Instant quoting: Transparent pricing and lead times upfront for informed manufacturing decisions.

-

Complete finishing services: Surface finishing options from anodizing to polishing.

-

Scalable volumes: From single prototypes to production runs with consistent quality.

Our network delivers the precision, speed, and reliability engineers need to bring cylindrical components from concept to production.

Need a material that holds up under pressure? Upload your CAD file to get a free, instant quote.

Get a quoteFrequently asked questions

What’s the difference between CNC turning and CNC milling?

In turning, the workpiece rotates while the tool stays still. In milling, the tool rotates while the workpiece stays fixed. Turning is ideal for round parts, while milling is better for prismatic or complex shapes.

What’s the difference between a CNC lathe and a mill-turn center?

A CNC lathe handles basic two-axis turning, perfect for simple cylindrical parts. A mill-turn center combines turning and milling, with live tooling and multi-axis movement for more complex geometries in one setup.

What tolerances can CNC turning achieve?

Standard tolerances are ±0.125 mm (±0.005"), with achievable tolerances down to ±0.025 mm (±0.001") on critical features using finishing passes.

What surface finishes can you get with CNC turning?

Turned parts naturally achieve excellent surface finishes (0.8–3.2 μm Ra). Post-processing like anodizing or bead blasting can further enhance appearance and performance.

What’s the maximum size part you can turn?

Our network can produce turned parts up to 431 mm (17") in diameter and 990 mm (39") in length, with some specialized machines capable of even larger sizes.

What's the best material for learning CNC turning?

Aluminum 6061 offers excellent machinability, good surface finish, and forgiving cutting characteristics, making it ideal for both learning and production applications.