Snap-fit joints connect two 3D-printed components using interlocking features. They are a low-cost and time-saving connection method that can reduce part count in an assembly. They also enable rapid assembly and disassembly.

This article covers the basics of snap-fit joints for 3D printing, what to consider when designing snap-fits with plastics and thermoplastics, and which 3D printing process is optimal for manufacturing high performing snap-fits.

Watch before you read: does Protolabs Network have a snap-fit tutorial?

Yes. We have a tutorial to help engineers design high-performance snap-fits. Before or after this guide, watch the video for step-by-step instructions on 3D printing snap-fit connectors.

What are snap-fit joints (or connectors/clips)?

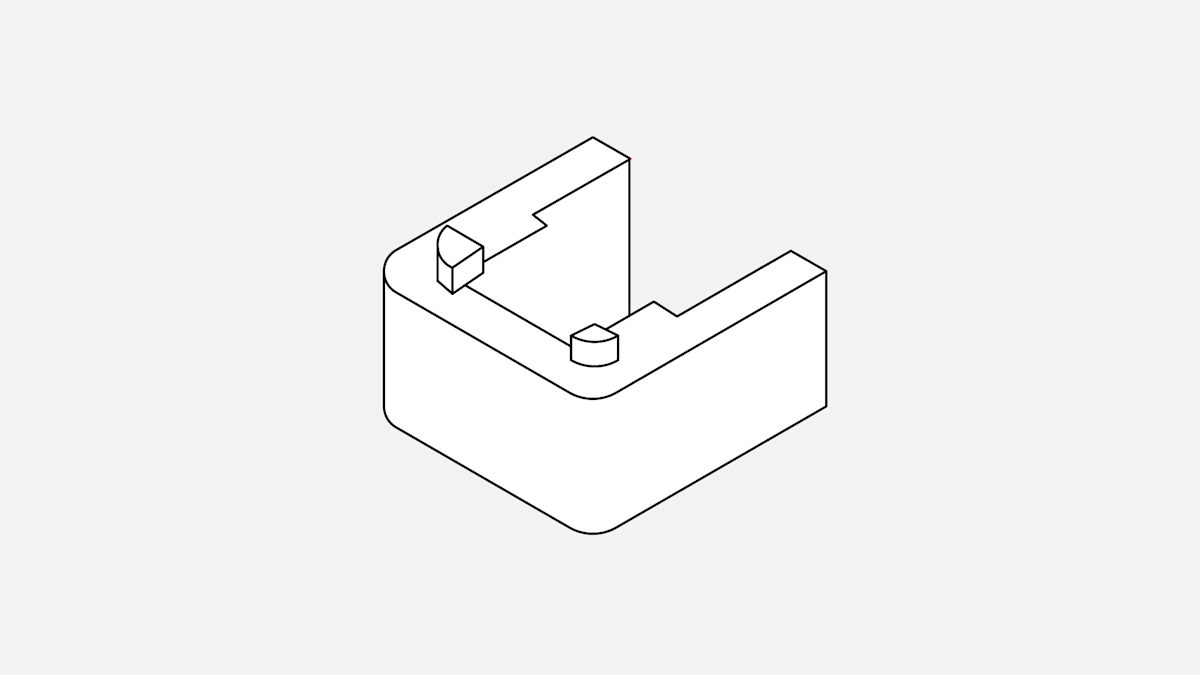

A snap-fit joint is a cost-effective and simple way to attach two 3D printed plastic components. Also called a connector or clip, a snap-fit typically uses a small, flexible protrusion such as a bead, stud or hook, and a matching recess that deflects and captures the protruding feature. When the features click into place, they form a robust interlocking connection.

After engagement, an integral undercut retains the two components. Depending on the undercut geometry, the connection can be designed as permanent. With proper design and material selection, a snap-fit can be cycled many times without noticeable mechanical fatigue.

There are many snap-fit types and geometries that follow the same principle of two interlocking features.

Common types of snap-fits: cantilever and annular joints

The two most common and effective snap-fit connectors for 3D printed parts are cantilever and annular joints. The sections below explain each type.

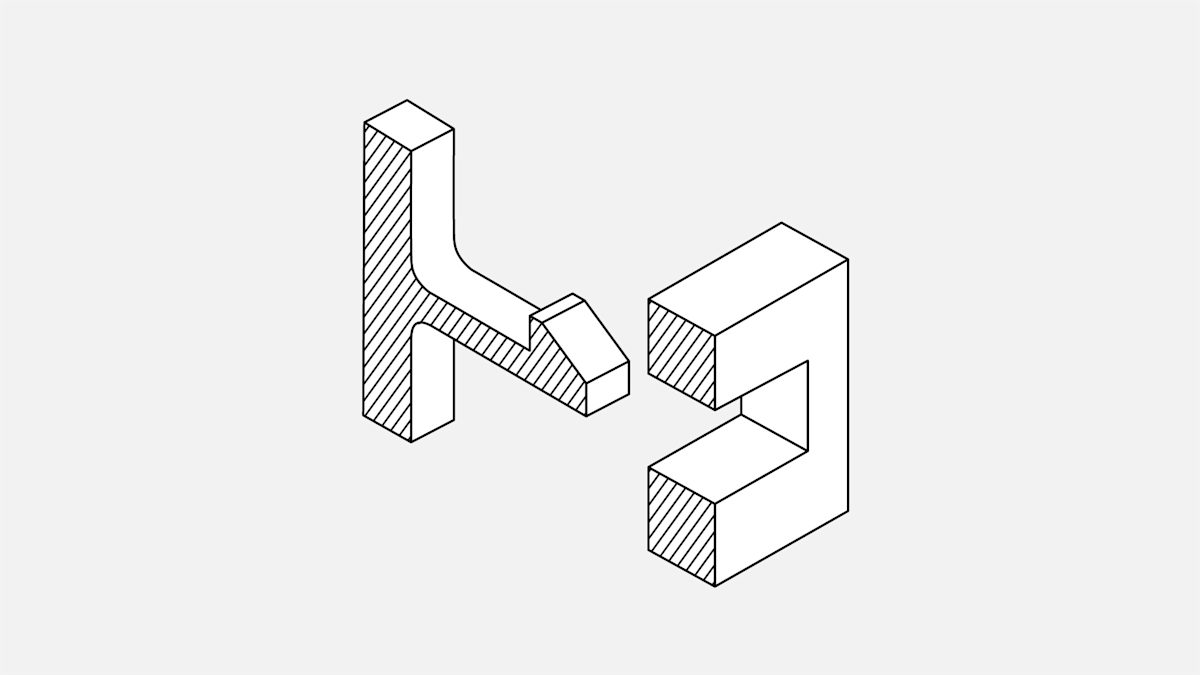

Cantilever snap-fit joints

The most common snap-fit is the cantilever. It uses a flexible protrusion, such as a bead or hook, at one end and a structural support at the other. During assembly, the protrusion deflects as it enters the opening, then returns to engage an undercut and lock the connection in place.

Cantilever snap-fits are straightforward to design and intuitive to assemble and disassemble. For many applications, cantilever snap-fit connectors are the most cost-effective way to join 3D printed components.

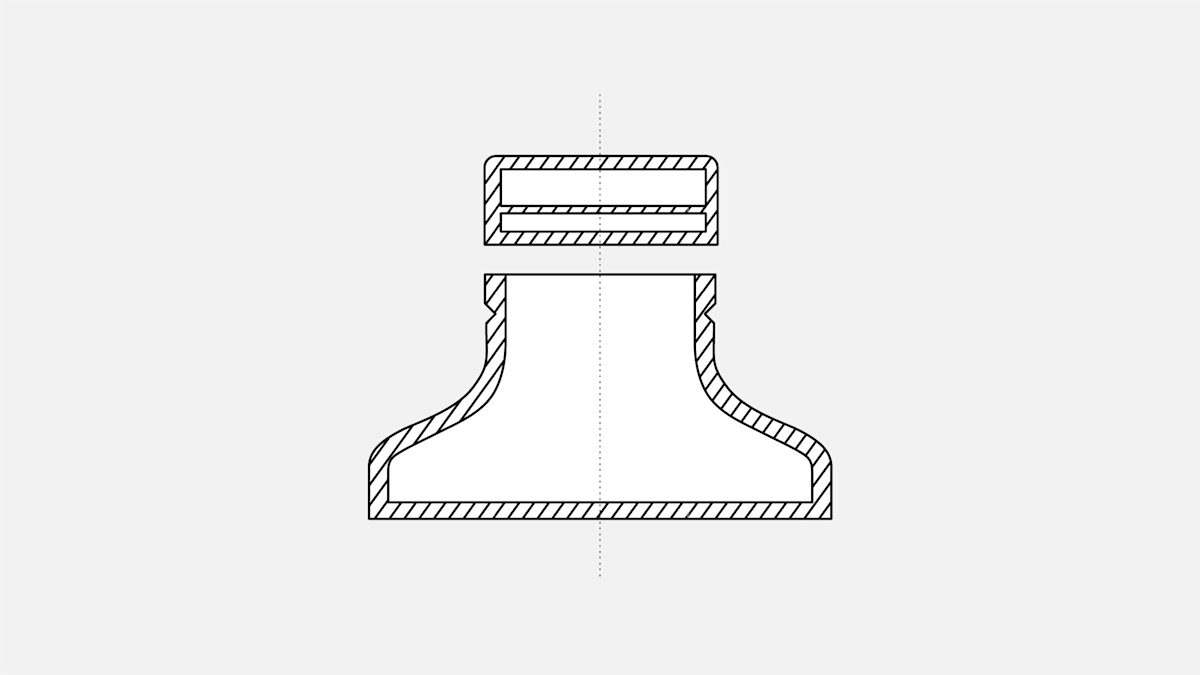

Annular snap-fit joints

Annular snap-fit joints use hoop strain to retain a press-fit part. Common examples include bottle caps and pen caps. With proper geometry and material selection, an annular snap-fit can provide a watertight seal at the joint.

What are the advantages of snap-fitting with 3D printing?

While injection molding is often the more robust method for production snap-fit joints, 3D printing is a viable alternative with the right design and material.

3D printed snap-fits avoid many injection molding constraints, such as required draft, parting lines, uniform wall thickness and limits on undercuts, and they can be modified quickly. This makes them well suited to rapid prototyping and design validation where clearance and fit are critical. For this reason, engineers often 3D print snap-fits for enclosures during development.

What materials are used for 3D printing snap-fit joints?

Each 3D printing process has advantages and limitations for snap-fit connectors, driven largely by the materials it uses. Material selection determines flexibility, fatigue resistance and durability, which are critical for reliable snap-fit performance.

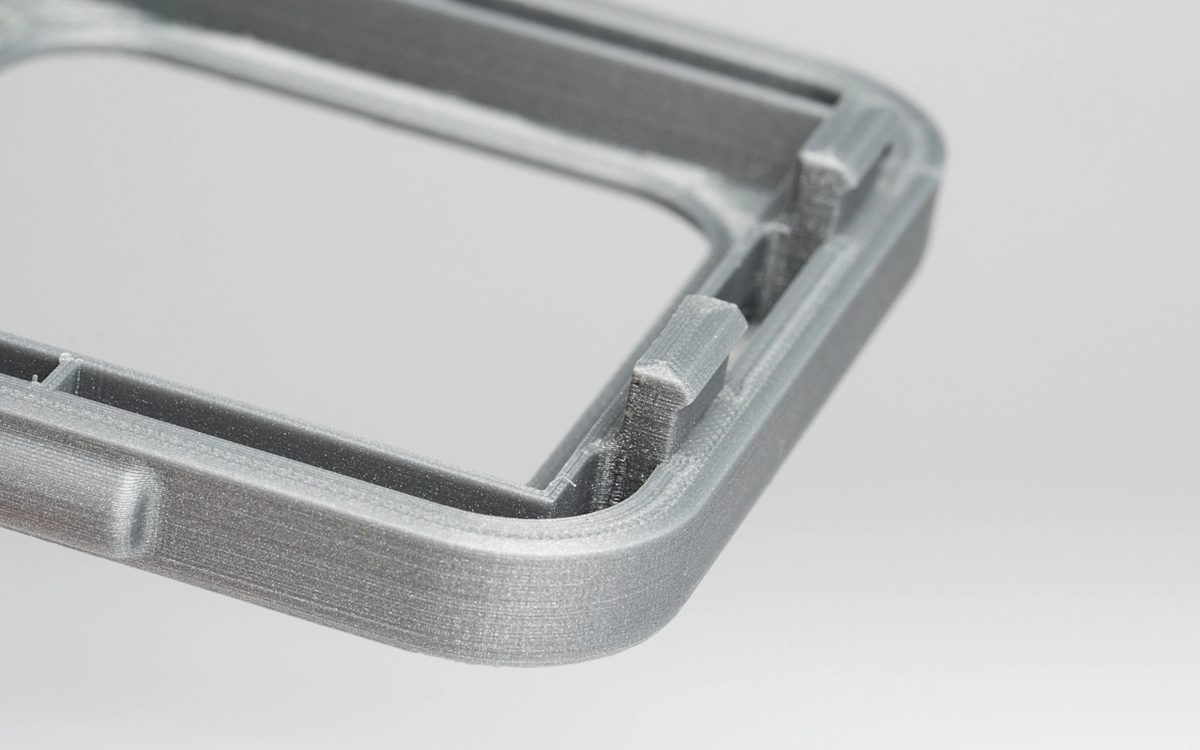

FDM is often the most cost-effective method to 3D print snap-fit connectors. It is effective, but accuracy is lower than other processes. When using FDM, choose strain-resistant materials such as ABS, nylon and TPU.

SLA resins can be used for snap-fit joints, but they are relatively brittle, which increases the risk of failure under repeated cycling. When using this process, choose a durable SLA resin for improved performance.

SLS is generally more suitable than FDM and SLA for functional snap-fit prototypes and end-use parts that will be opened and closed many times. For maximum tear resistance, specify SLS nylon.

Similar to SLS, MJF (HP Multi Jet Fusion) is well suited for manufacturing snap-fit connectors. MJF produces robust parts in nylon PA 12 and select nylon and polypropylene options. Follow key design guidelines for best results. For example, use a minimum thickness of 1 mm at the cantilever base and a minimum common overhang depth of at least 1 mm.

What are common problems with designing snap-fit joints?

The snap-fit design process varies by technology, material and application. Engineers often encounter these challenges with 3D printed snap-fits:

-

Sharp internal corners concentrate stress in the cantilever, increasing the risk of breakage.

-

Constant loading causes creep in plastics and thermoplastics, which weakens the joint over time.

-

Incorrect gaps and clearances create tolerance issues that hinder proper fit.

-

Frequent assembly and disassembly introduce fatigue, leading to potential failure.

In general, snap-fits experience the highest stress during engagement and should return to a neutral position once assembly is complete. Depending on undercut geometry, snap-fit joints can be designed to be permanent. With proper geometry and material selection, a snap-fit can be cycled many times without noticeable fatigue.

What are the right tolerances for snap-fit joints?

3D printing properties vary with printer calibration, material and process, so there are no universal tolerance rules for snap-fit joints and connectors.

We recommend these nominal clearances:

-

FDM (fused deposition modeling): 0.5mm

-

SLA (stereolithography), SLS (selective laser sintering) and MJF: 0.3mm

What are the best practices for designing 3D-printed snap fits?

When designing snap-fit joints for 3D printed parts, account for features that reduce stress and strain in the assembly. The following guidance outlines best practices for engineers designing snap-fit joints for additive manufacturing and outsourced production.

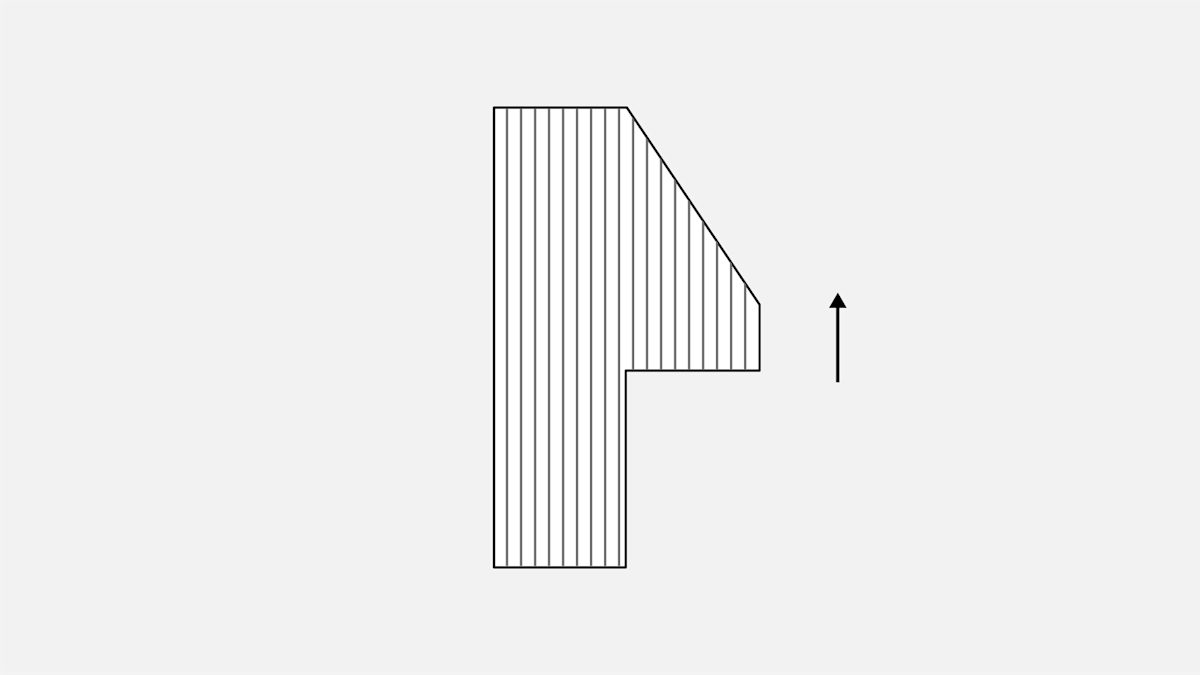

Taper the design

A constant-thickness snap-fit cantilever produces uneven strain, with peaks at the root. Taper the beam so the cross-section decreases toward the tip. This reduces material use, lowers peak stress and evens strain distribution along the cantilever.

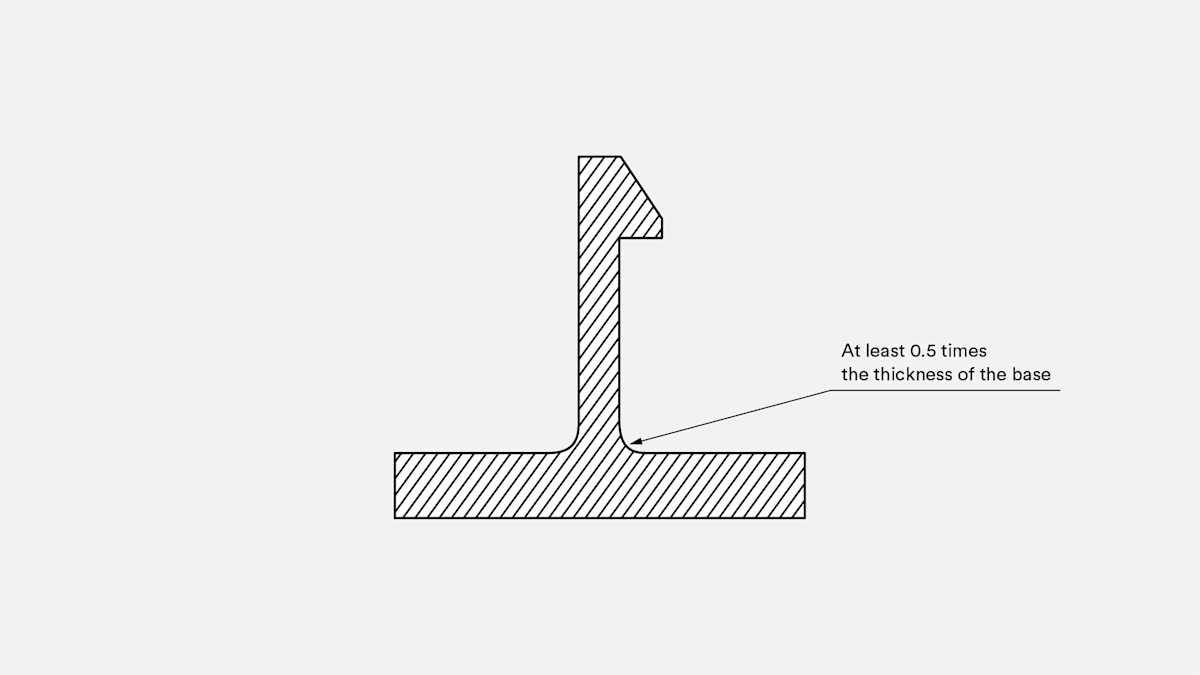

Fillet the base of the cantilever:

Add a fillet at the cantilever root to distribute stress over a wider area and strengthen the connection. Specify a fillet radius at least 0.5 times the cantilever base thickness.

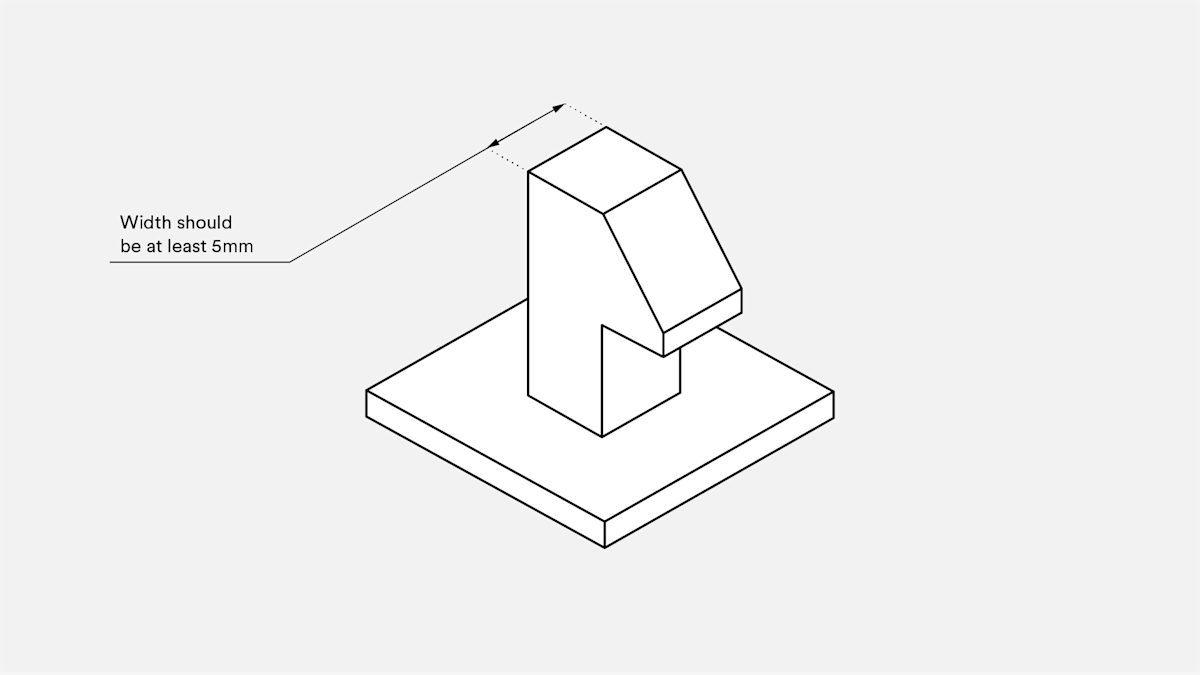

Increase the width:

Where feasible, increase the clip width to improve strength. Iterate to reach the required stiffness, and use a minimum width of 5 mm.

Deflect during assembly:

To minimize stress and increase joint strength, the snap-fit cantilever is deflected only during assembly, not while components are engaged in service, for durable, reliable performance in production assemblies.

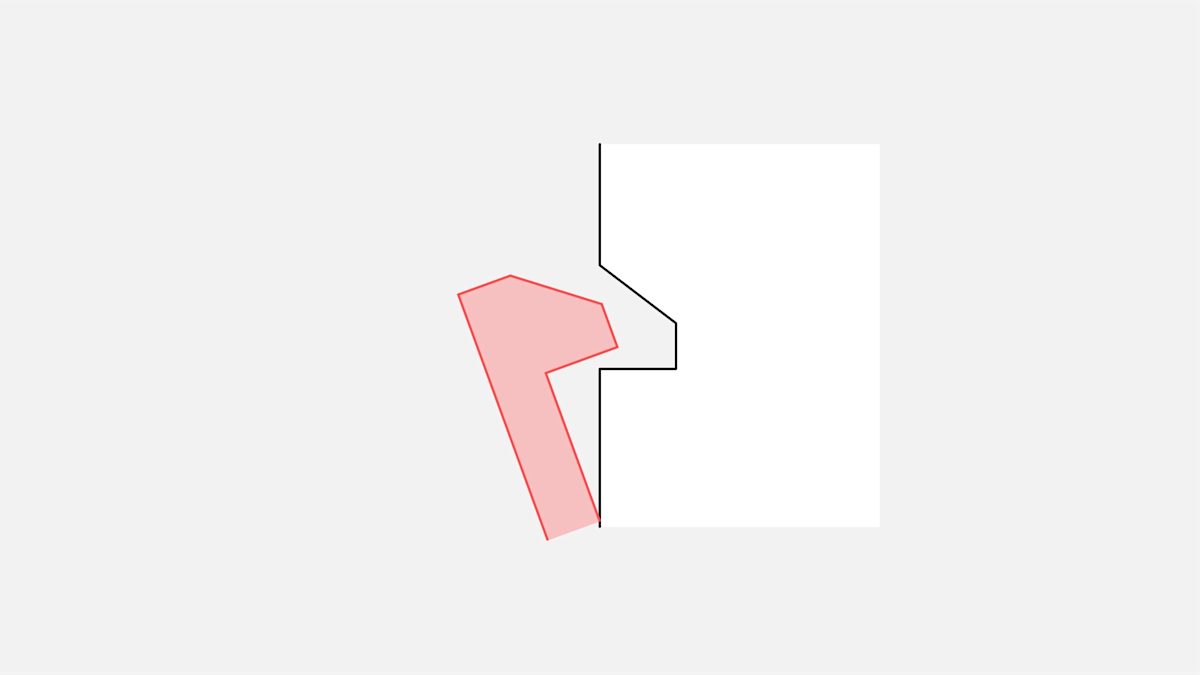

Consider build direction:

If feasible, avoid snap-fit cantilevers built vertically in the Z direction. Anisotropy from layer bonding in 3D printing lowers strength and raises the risk of fracture.

Add lugs:

Add lugs to the assembly to improve component alignment and to transfer part of the shear load that would otherwise be carried by the snap-fit clips.

Our top tips & tricks for designing snap-fit joints

-

Apply sound design practices that limit stress and strain in engineered snap-fit joints. Use fillets, select a favorable build direction, and include locating lugs; control strain with tapered profiles and adequate cantilever width.

-

Set process-appropriate tolerances. Use 0.5 mm for FDM snap-fit connectors and 0.3 mm for SLS, SLA, MJF, and material jetting to support consistent assembly in industrial 3D printing.

-

Select materials with the application in mind. Prototyping plastics confirm geometry but are typically weaker than SLS nylon or material jetting resins, so choose functional or end-use grades for connectors that will be opened and closed repeatedly.

To explore 3D printing further, check out our full guide for a comprehensive overview and detailed design and manufacturing tips.

To learn more about industrial 3D printing, read our guide for process selection, design rules, and manufacturing guidance. When ready to move into production, upload CAD models to the Protolabs Network platform for an instant quote and built-in DFM analysis, or contact networksales@protolabs.com to be connected with a specialized account manager.

Frequently asked questions

What are snap-fit joints used for?

Snap-fit joints mechanically connect 3D-printed and injection molded plastic components quickly and cost-effectively for production assemblies.

How long do snap-fit joints last?

Snap-fit joints undergo cyclic bending in service and will fatigue over time. Service life depends on material properties, 3D printing technology, geometry and strain limits, and environmental conditions; with sound design, build orientation, and process control, 3D-printed snap-fits can rival injection molded connectors.

What materials are best for designing snap-fit joints?

Tough, ductile polymers such as ABS, PETG, and nylon (e.g., PA12) are preferred for snap-fit connectors, while brittle grades like PLA and standard SLA resins are less suitable. Select material based on required deflection, fatigue life, and joint type.

What are the right tolerances for snap-fit joints?

For FDM snap-fit connectors, specify 0.5 mm clearance. For SLS, SLA, MJF, and material jetting, specify 0.3 mm to support consistent assembly.

Is 3D printing better than injection molding for producing snap-fit joints?

3D printing has fewer design constraints than injection molding, enabling complex geometries and fast iteration for prototyping and low volumes, while molding is preferred for high-volume, repeatable snap-fit production.

How do you design better snap-fit joints for 3D printing?

For industrial 3D printing, reduce stress and strain in the joint to improve service life and assembly consistency. Use tapered profiles, add fillets at the cantilever root, and include locating lugs to aid alignment and share shear load.

What's the best material for 3D printing snap-fit joints?

SLS nylon (PA12) is recommended for many applications because it offers high tear resistance and good fatigue performance.