In CNC machining, whether producing a single prototype or scaling to high volumes, reducing manufacturing cost is often the priority. Design choices help keep pricing down. By following design for machinability (DFM) guidelines, cost-effective parts can be manufactured while meeting functional performance requirements.

This article provides practical CNC machining design tips. It outlines the main cost drivers in CNC machining and presents proven guidelines to reduce project cost.

Did you know we offer local sourcing for CNC machining?

How much does CNC machining cost?

A quote for CNC machined parts depends on several factors:

-

Machining time: Longer cycle times increase cost. Machining time is often the primary cost driver in CNC machining, especially in high volume production where minor design issues can reduce economies of scale.

-

Start-up costs: These cover CAD file preparation and process planning. They are significant at low volumes but remain fixed. If the design and surface finish scale efficiently, unit price decreases through economies of scale.

-

Other manufacturing costs: Tight tolerances and hard-to-machine features, such as very thin walls, can require special tooling, stricter quality control and extra operations at lower cutting speeds. These increase total machining time and overall cost.

-

Material cost: Raw material price and machinability significantly influence CNC machining cost. Selecting a machinable material and optimizing the design to minimize waste reduces expense.

Understanding CNC machining cost drivers helps engineers optimize designs and reduce total cost, especially for outsourced CNC production

How to reduce CNC machining cost

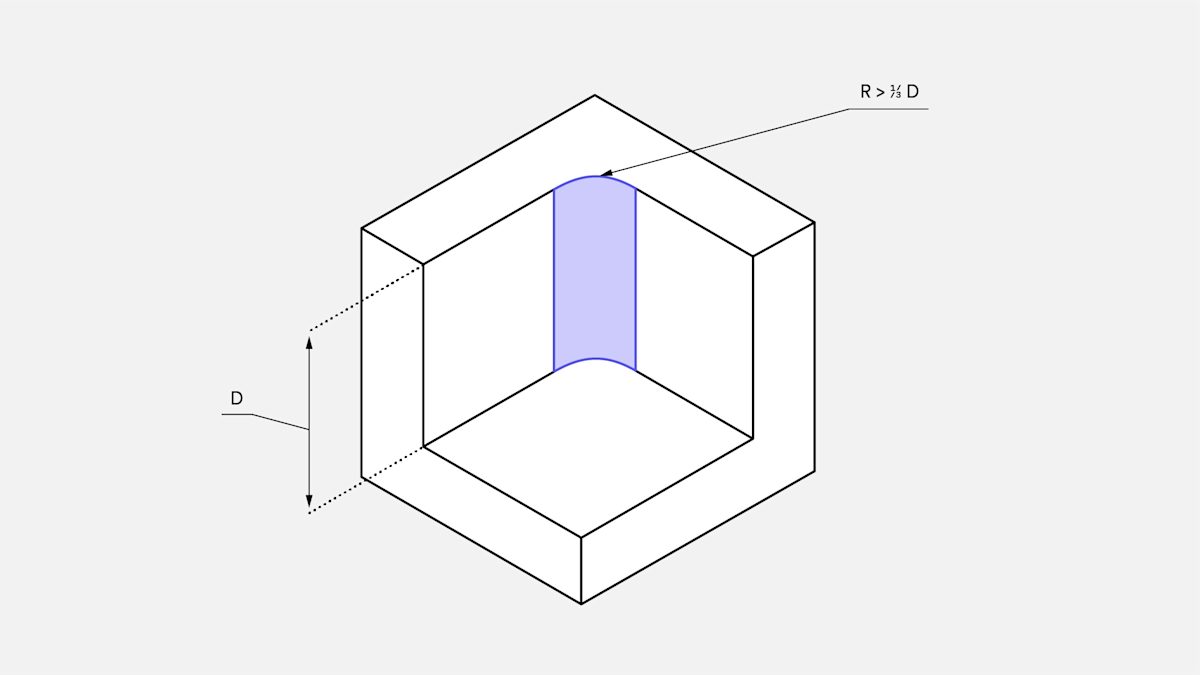

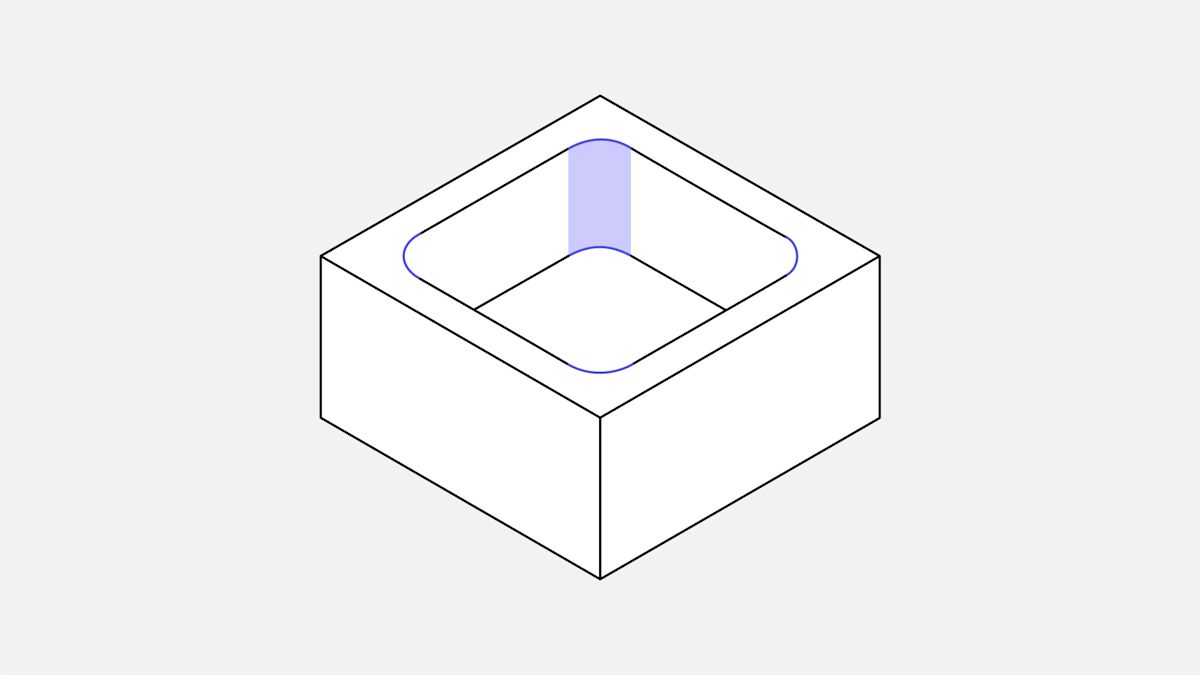

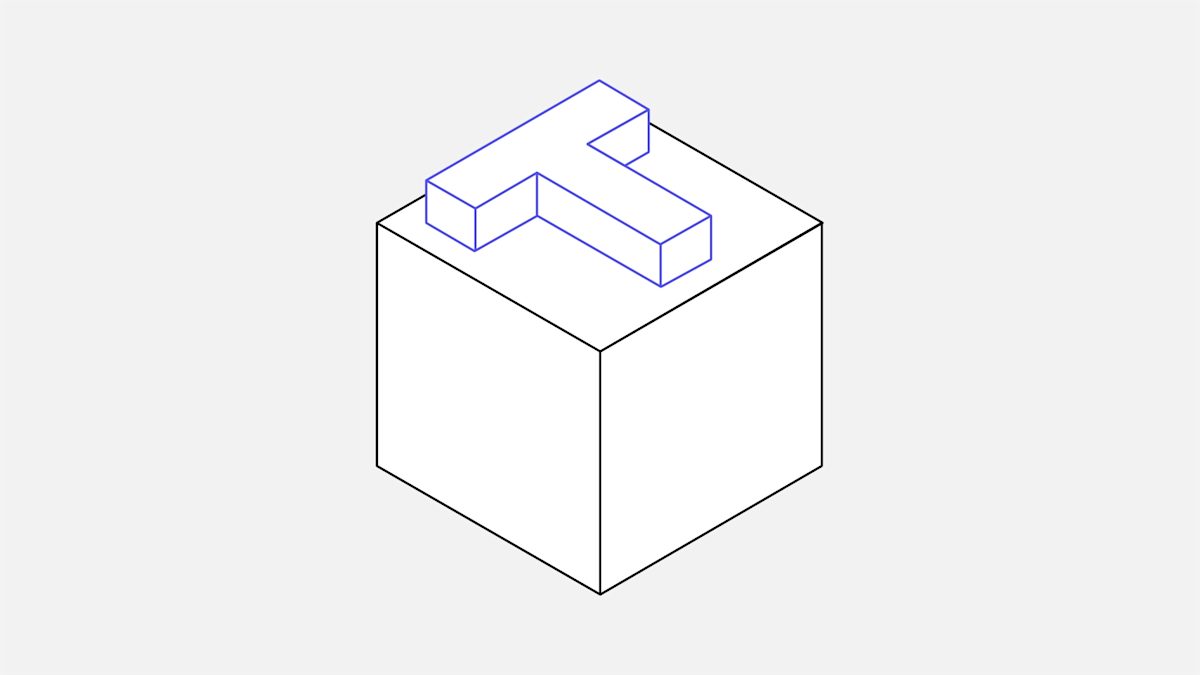

1. Add a radius in internal vertical edges

CNC milling tools are cylindrical and leave an internal radius in pocket corners. Reducing the corner radius requires a smaller diameter tool, which needs multiple passes at lower speeds because smaller tools remove less material per pass. This increases machining time and cost.

To minimize cost:

-

Specify a corner radius at least one third of the cavity depth; larger radii lower machining time.

-

Use the same radius on all internal edges to eliminate tool changes.

-

At the cavity floor, apply a small radius (0.5 or 1 mm) or none.

Good to know: Specify a corner radius slightly larger than the cutter radius to reduce tool load and cost. For a 12 mm deep cavity, use a 5 mm or larger corner radius. This lets an 8 mm diameter tool run at higher speeds.

Pro tip: When sharp internal corners are required, such as fitting a rectangular part in a cavity, add reliefs or undercut features instead of reducing the internal corner radius, as shown below.

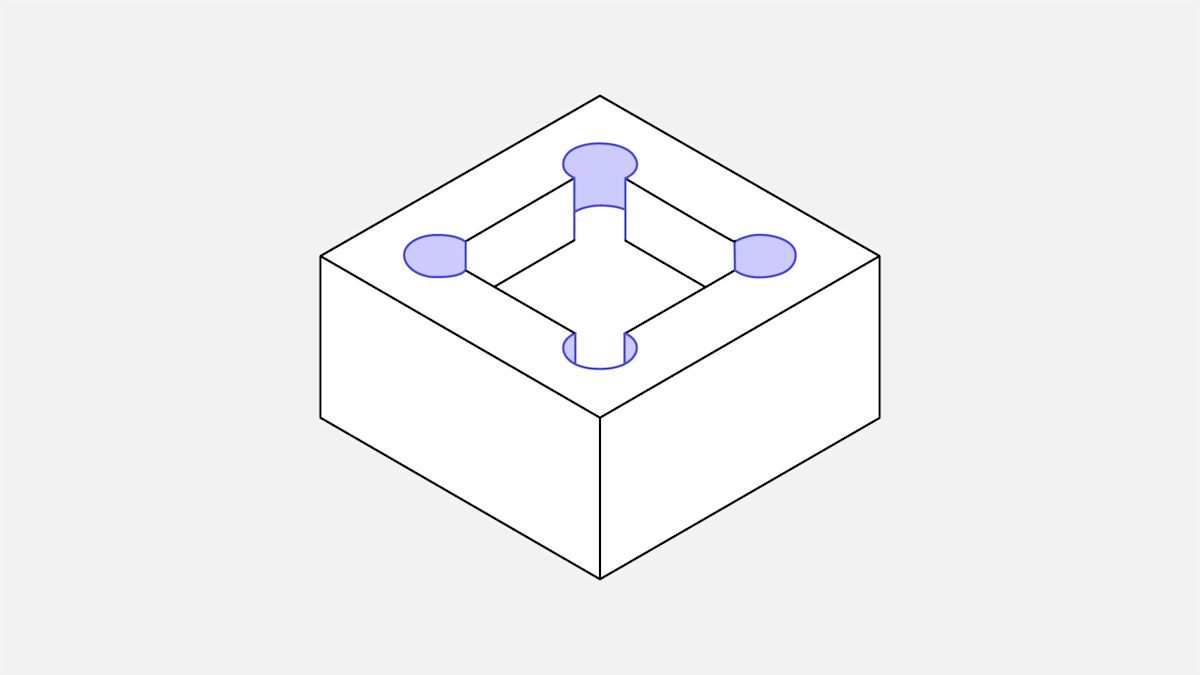

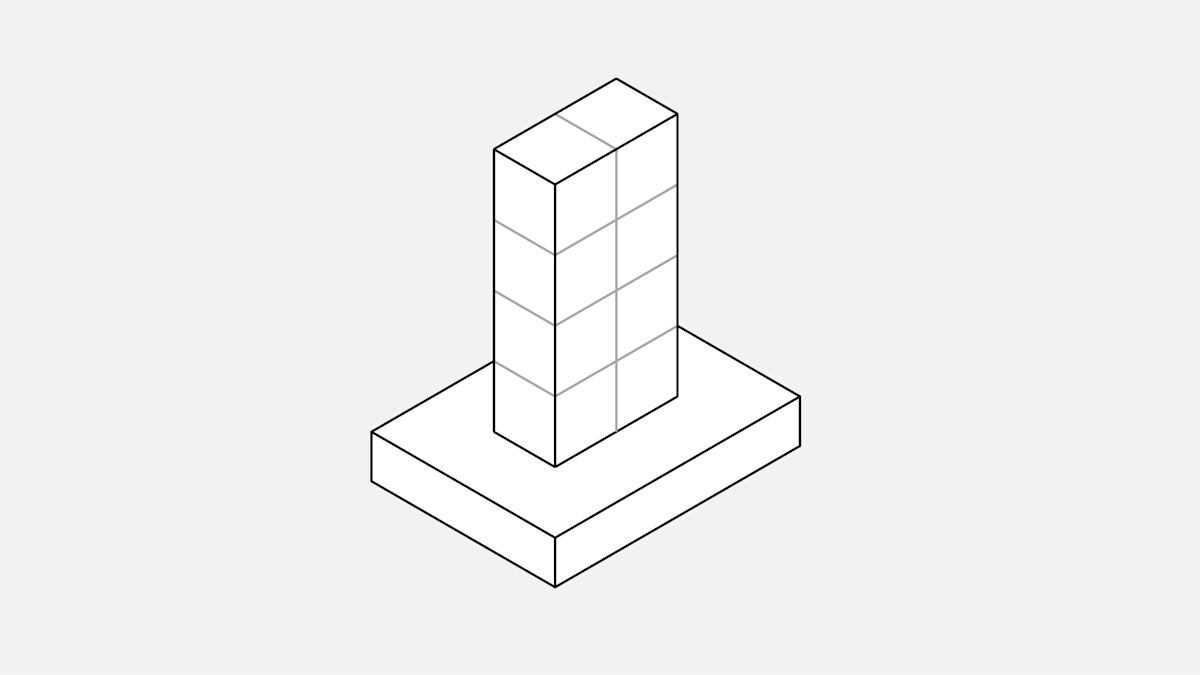

2. Limit the depth of cavities

Machining deep cavities increases CNC machining cost because removing large volumes of material is time consuming and wasteful.

CNC tools have limited cutting length and perform best when cavity depth is about two to three times the tool diameter. For example, a 12 mm end mill can machine cavities up to about 25 mm deep. Deeper cuts, up to four times the diameter or more, are possible but increase cost because special tooling or multi-axis CNC systems are required.

To minimize cost:

-

Limit cavity depth to no more than four times the feature length, defined as the largest dimension in the XY plane.

-

Adjust internal corner radii accordingly and refer to tip 1 if needed.

3. Increase the thickness of thin walls

Unless weight is a primary requirement, thicker solid sections improve stability and reduce machining cost. Thin walls require multiple passes at low cutting depths to limit deformation or fracture. Thin features are also prone to vibration, which makes accurate machining difficult and increases cycle time.

To minimize cost:

-

For metal parts, design walls thicker than 0.8 mm to improve stability and reduce machining time.

-

For plastic parts, keep minimum wall thickness above 1.5 mm.

Good to know: The minimum achievable wall thickness is about 0.5 mm for metals and 1.0 mm for plastics. Assess the machinability of these features case by case.

Important: Thin walls can cause issues when holes or threads are placed near an edge. Allow adequate edge distance in CNC machining design.

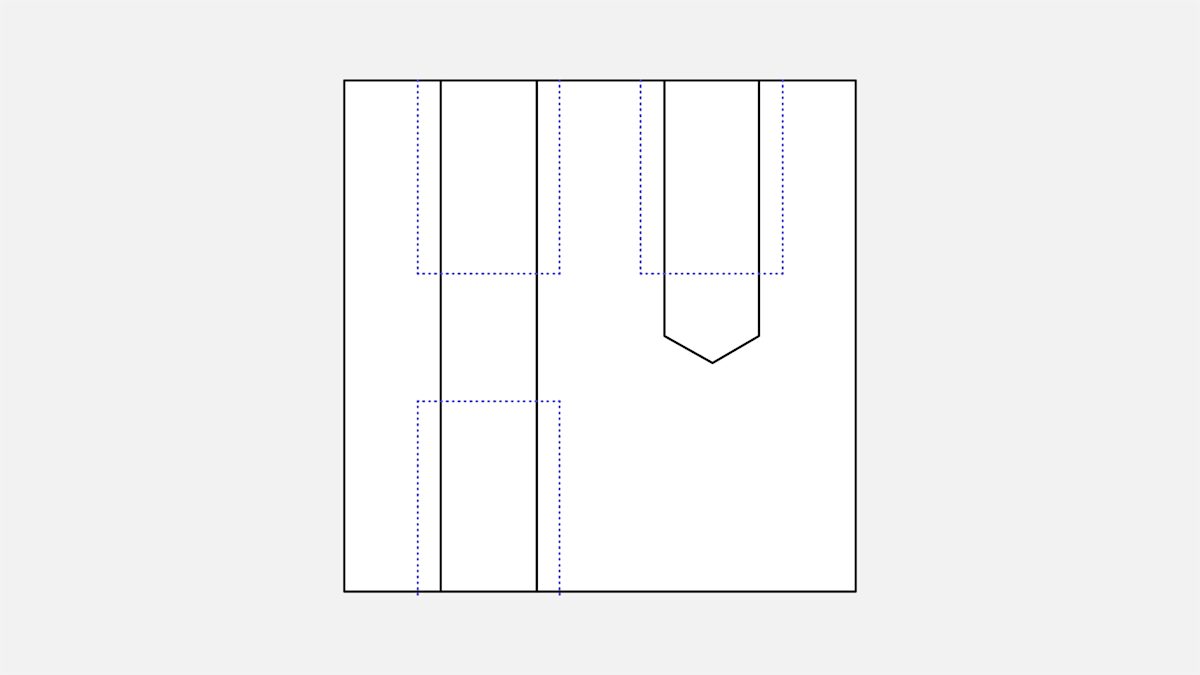

4. Limit the length of threads

Excessive thread length increases CNC machining cost due to special tooling and longer cycle times. Thread engagement beyond 1.5 times the hole diameter offers little additional joint strength.

To minimize cost:

-

Limit thread length to no more than three times the hole diameter.

-

For blind holes, leave an unthreaded relief at the bottom at least half the hole diameter.

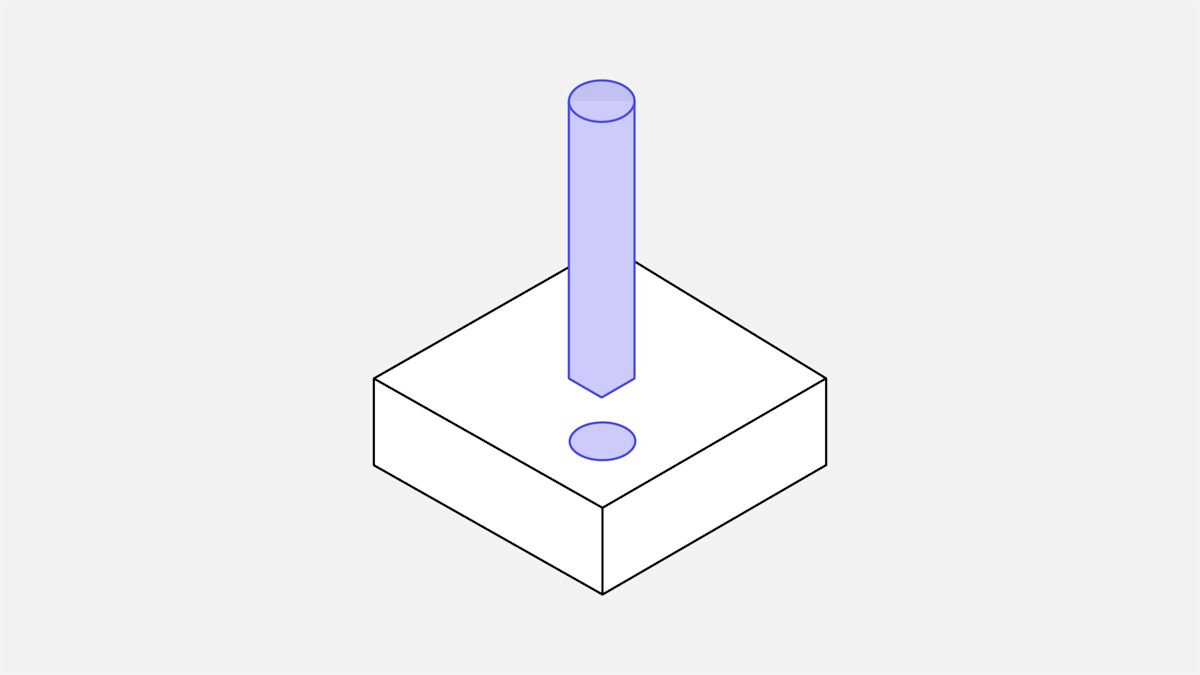

5. Use standard hole sized

Holes can be CNC machined quickly and accurately with standard drill bits. Nonstandard diameters require an additional machining step, which increases cost. When possible, specify through holes instead of blind holes because they are easier to machine.

Limit hole depth to four times the diameter. Deeper holes, up to about 10 times the diameter, are possible but increase cost due to longer machining time.

To minimize cost:

-

Specify hole diameters in 0.1 mm increments up to 10 mm, and in 0.5 mm increments above 10 mm.

-

When designing in inches, use standard fractional sizes or consult a fractional drill bit size chart.

Using standard thread sizes in CNC designs reduces lead time, shortens machining time, and lowers overall cost.

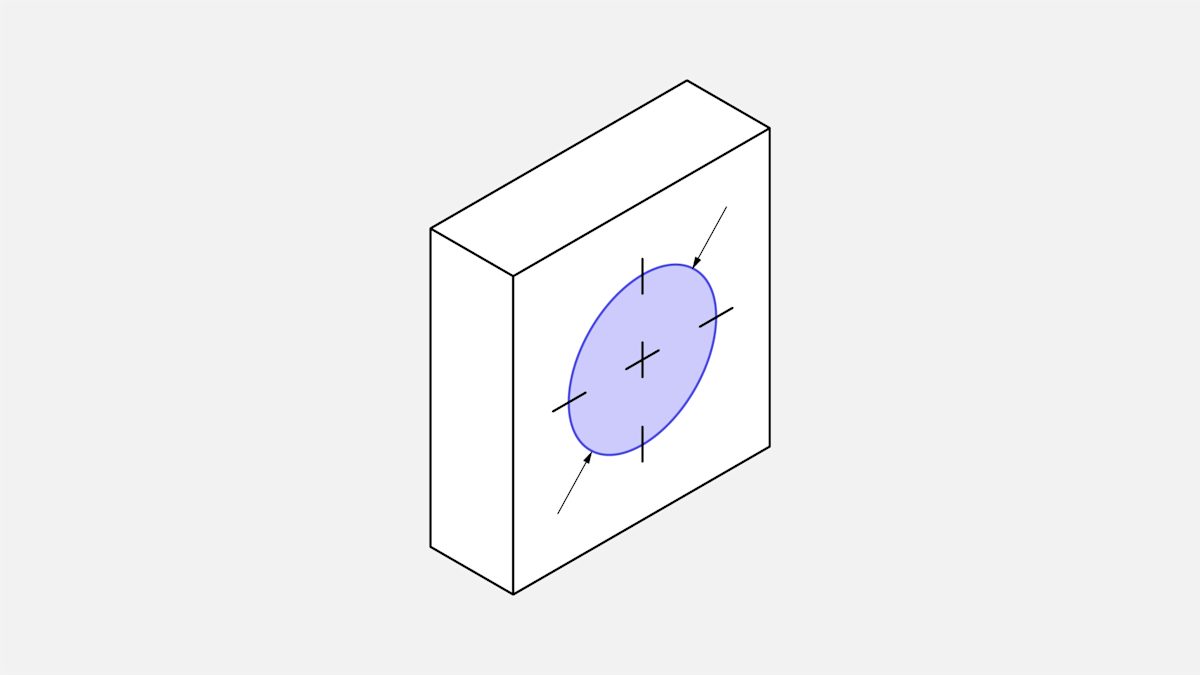

6. Only specify tolerances when necessary

Tight tolerances increase CNC machining cost and should be applied only when required. If no specific tolerance is defined on the technical drawing, parts are machined to a standard tolerance (±0.125 mm or better), which is sufficient for most noncritical features.

To minimize cost:

-

Apply tighter tolerances only when function requires them.

-

Use a single datum, such as the intersection of two edges, as the reference for all toleranced dimensions.

Pro tip: Use geometric dimensioning and tolerancing (GD&T) on technical drawings to reduce CNC machining costs. GD&T controls features such as flatness, straightness, circularity and true position. It often allows looser size tolerances while meeting function, but it requires advanced design knowledge to apply effectively.

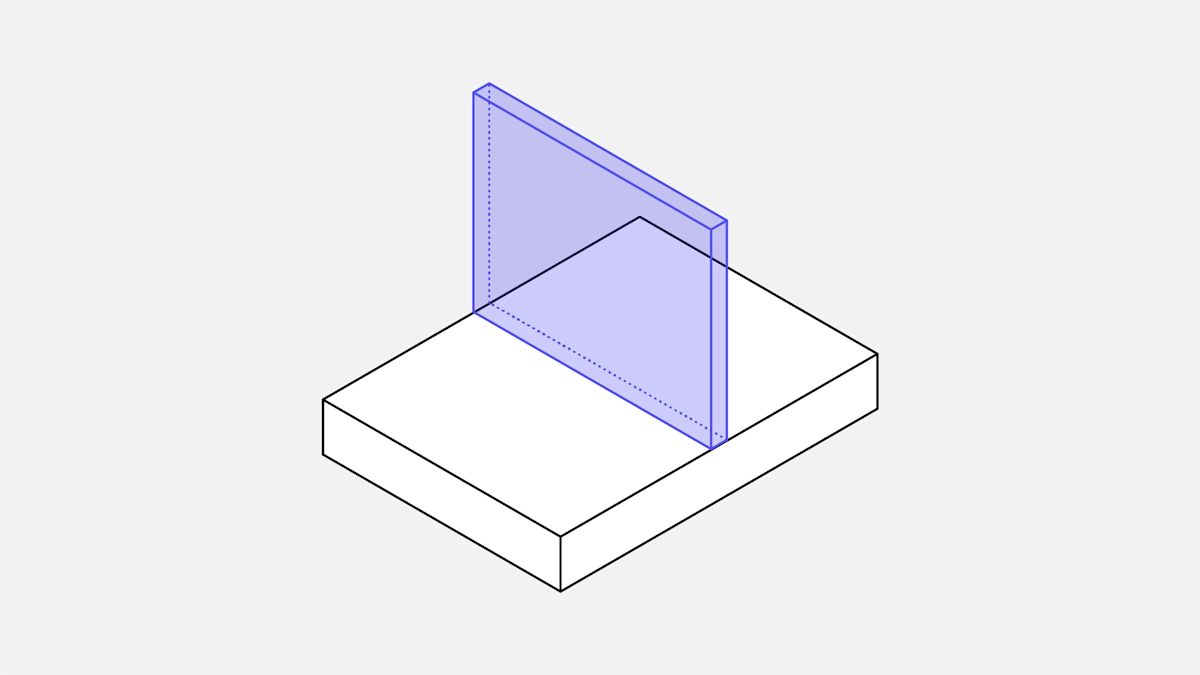

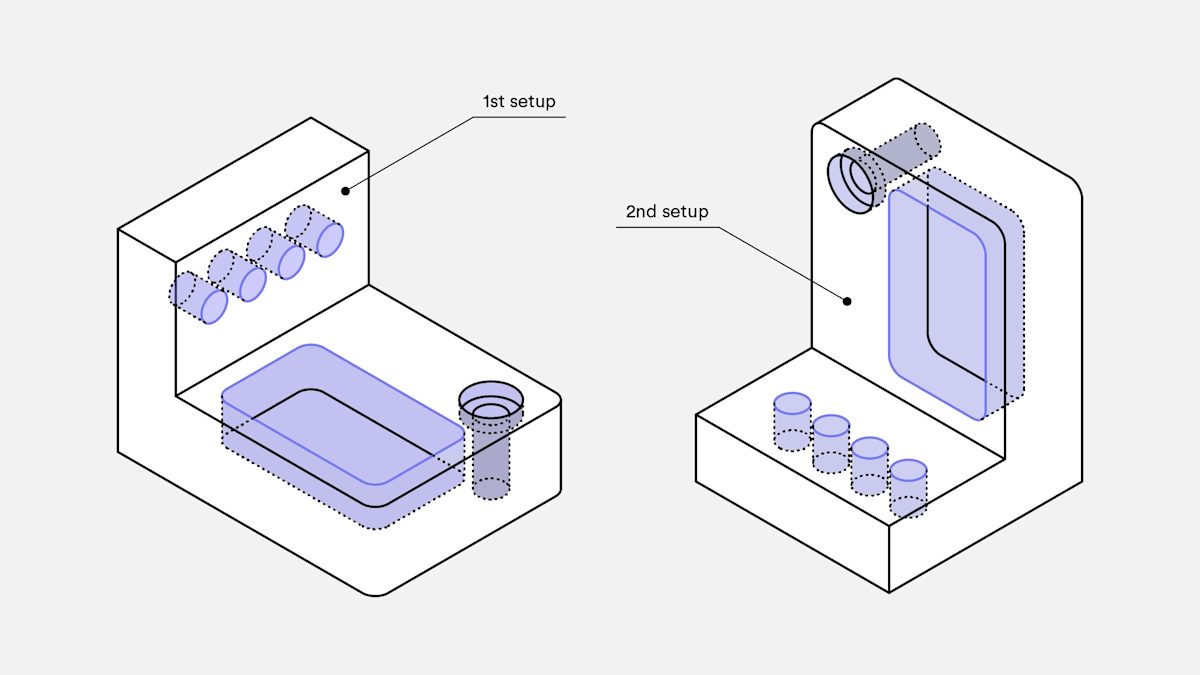

7. Minimize the number of machine setups

Design parts for CNC machining in as few setups as possible, ideally a single setup. For example, blind holes on both faces require two setups because the part must be rotated to access each side.

Rotating or repositioning a part increases CNC machining cost because it is often a manual step. Complex geometries may require custom fixturing, which adds expense. Highly complex shapes may need multi-axis CNC machining, further increasing cost.

Consider splitting the design into multiple components that can each be CNC machined in a single setup, then bolted or welded together. This also helps for parts with very deep pockets.

To minimize cost:

-

Design parts with simple 2.5D geometry that can be machined in a single setup.

-

If a single setup is not feasible, split the design into multiple components for post-machining assembly.

8. Avoid small features with high aspect ratio

Small, slender features with a high width-to-height ratio are prone to vibration, which makes precise machining difficult.

To minimize cost:

-

Maintain a width-to-height aspect ratio below 4:1 for small features.

-

Add bracing around small features or tie them to a wall to increase stiffness.

9. Remove all text and lettering

Adding text to a CNC machined part can significantly increase cost because it requires additional toolpaths and machining time. Surface finishing methods such as silk screening or painting are more cost-effective for adding text to CNC machined parts.

To minimize cost:

-

Remove text and lettering from CNC machined parts.

-

If text is required, use engraving rather than embossing.

-

Use a sans serif font at least size 20, such as Arial or Verdana.

10. Consider the machinability of the material

Machinability describes how easily a material can be cut in CNC machining. Higher machinability enables faster cutting and lowers cost. It depends on the material’s physical properties. In general, softer and more ductile metal alloys are easier to machine.

C360 brass has excellent machinability and supports very high cutting speeds. Aluminum alloys such as 6061 and 7075 machine easily at slightly lower speeds than C360.

Stainless steel generally has lower machinability than aluminum in CNC machining and often takes at least twice as long to machine. Machinability varies by grade. For example, 304 stainless steel has a machinability index around 45%, while 303 stainless steel, with similar composition, is about 78% and machines more easily.

In CNC machining, plastic machinability depends on thermal properties and stiffness, as many polymers can melt or deflect during cutting.

POM (Delrin) is the easiest plastic to machine, with ABS a close second. PEEK and nylon 6 are common engineering plastics that are more difficult to machine.

To minimize cost:

-

When possible, select a material with higher machinability, especially for larger production runs.

11. Consider the price of the bulk material

Bulk material cost can significantly affect the price of CNC machined parts.

The table below summarizes prices for common metal alloys and plastics in CNC machining for a 6 in x 6 in x 1 in sheet (approximately 150 x 150 x 25 mm).

| Material | Price |

|---|---|

| Aluminum 6061 | $25 |

| Aluminum 7075 | $80 |

| Stainless steel 304 | $90 |

| Stainless steel 303 | $150 |

| C360 brass | $148 |

| ABS | $17 |

| Nylon 6 | $30 |

| POM (Derlin) | $27 |

| PEEK | $300 |

Source: McMaster

Aluminum 6061 is among the most cost-effective options for CNC machined metal prototypes due to its low material cost and excellent machinability.

Metals with high machinability, such as 303 stainless steel and C360 brass, generally cost more and are better suited to larger production runs in CNC machining. At scale, faster cycle times and shorter machining offset the higher material cost.

For plastics, ABS, nylon, and POM (Delrin) are priced similarly to aluminum 6061, but they are more difficult to machine, which can increase overall CNC machining cost. PEEK is a high-cost material and should be specified only when its performance is essential.

To minimize cost:

-

Select a material with low raw material cost, especially for low-volume orders.

12. Avoid multiple surface finishes

Surface finishes improve the appearance and environmental resistance of CNC machined parts, but they add cost. Specifying multiple finishes on the same part increases cost further because it requires extra steps such as masking. For a summary of finish options and benefits, see our CNC surface finishes article.

To minimize cost:

-

Choose the standard "as machined" surface finish where possible.

-

Request multiple surface finishes only when necessary.

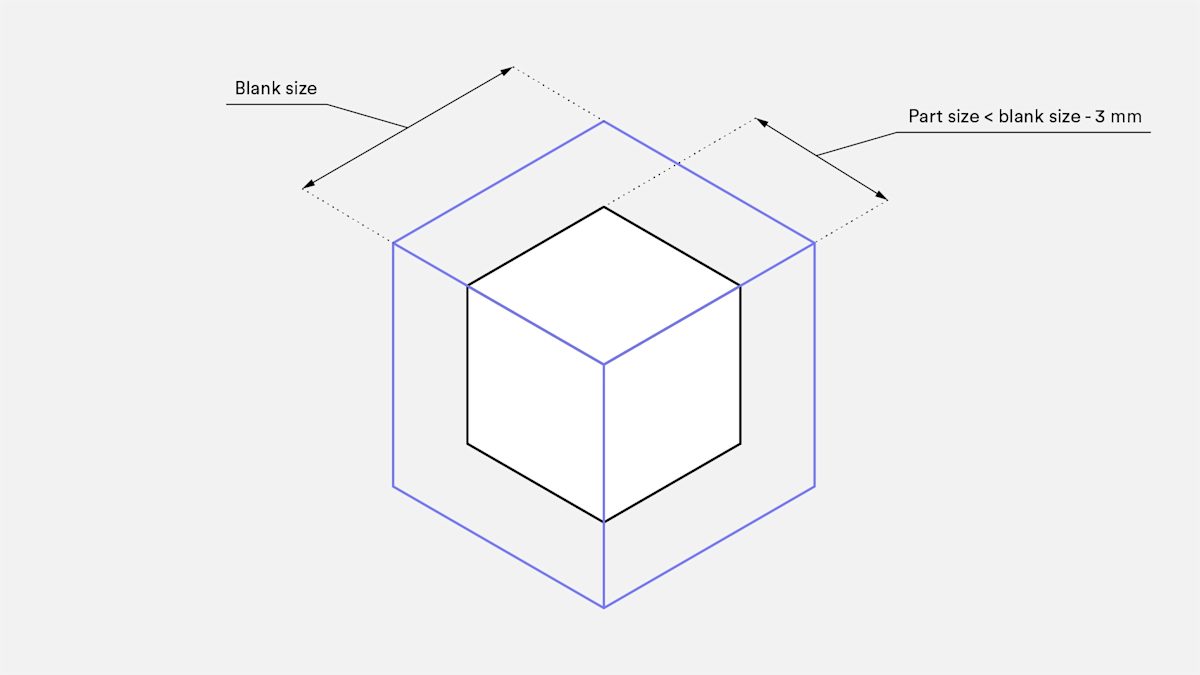

13. Account for blank size

Blank size affects overall cost. As a rule of thumb, select stock at least 3 mm larger than the finished part in all dimensions. This allows material to be removed from every edge to achieve final size and accuracy.

For example, a part with a 30 x 30 x 30 mm envelope typically requires a larger blank cut from a 35 mm sheet. If the envelope is reduced to 27 x 27 x 27 mm, a 30 mm sheet can be used instead, which saves material and reduces cost.

To minimize cost:

-

Design parts at least 3 mm smaller than the nearest standard blank size.

14. Take advantage of economies of scale

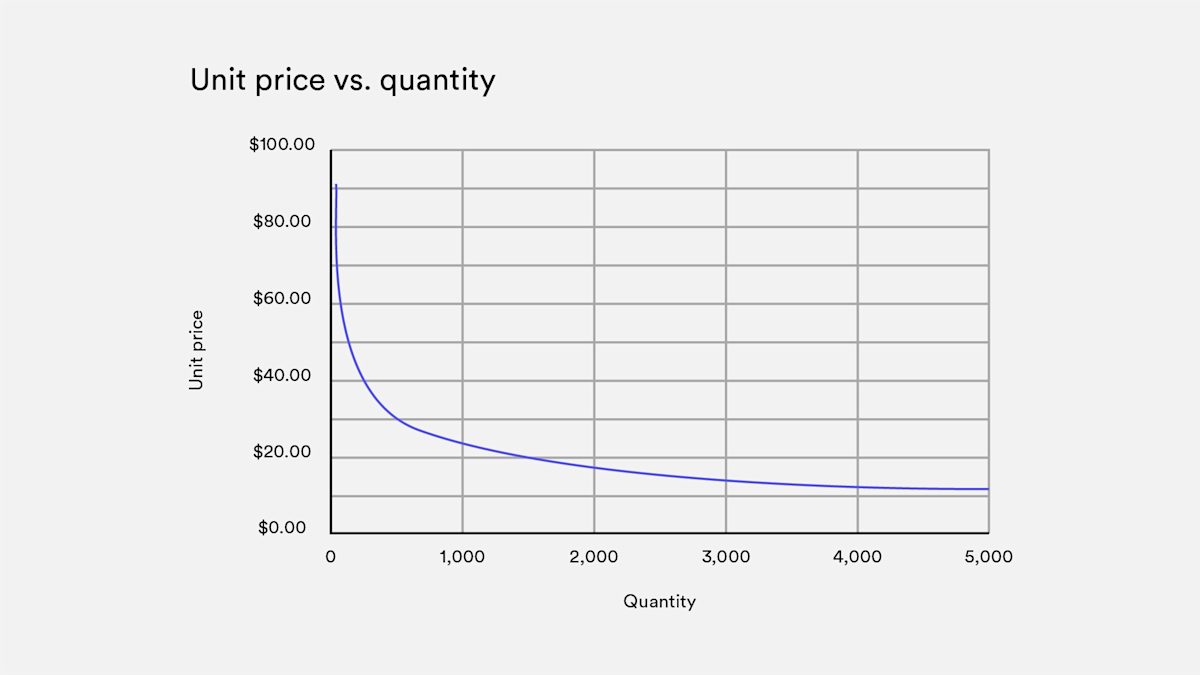

In CNC machining, order quantity strongly affects unit price. Start-up costs are relatively high, so at low volumes they make up a large share of the cost per part. As volume increases, these fixed costs are spread across more parts, reducing the unit cost.

The chart below shows the average unit price for 12 CNC machined parts in 304 stainless steel.

Unit price drops rapidly with quantity: increasing the order from one to five can cut price by about half, and very high volumes over 1,000 parts can reduce unit cost by five to ten times.

To minimize cost:

-

Take advantage of economies of scale by ordering higher volumes.

Best practices for lowering CNC costs

In conclusion, keep your CNC machining simple.

Complexity increases cost. Features that require special tooling or fixtures, multiple machine setups, or specialty materials raise pricing.

To reduce CNC machining cost, review these questions before requesting a quote:

-

Is the part designed to design for machinability (DFM) guidelines?

-

Are all features essential, or can any be removed or simplified while maintaining function?

-

Can the design be split into multiple parts that are easier to machine and assemble?

-

Can the design be modified to avoid multiple machine setups or special tooling?

-

Is there a lower cost or more machinable material that still meets the design requirements?

The present & the future of CNC machining

CNC machining capabilities continue to expand. Advances in tooling enable threading holes to full depth, and holes of almost any diameter can be produced with minimal impact on price using plunging tools and profile interpolation, such as a helical toolpath.

This article covers design for manufacturability tips that apply to any CNC system. Use these practical guidelines to design parts efficiently and prepare them for production. .

Download the CNC checklist for reducing costs

If you found this article useful and want an offline reference, download our CNC machining cost reduction checklist.